Chameleon fiber fabric processing technology

A color-changing fiber and processing technology, which is applied in the direction of synthetic resin layered products, textiles and papermaking, layered products, etc., can solve the problems of high cost, poor versatility, and inability to widely apply various fabric substrates, etc. Low consumption, good consumption, convenient and fast production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and a preferred embodiment.

[0021] The color-changing fiber fabric processing technology includes: the step of preparing the grafting mixture and the step of coating and transferring the grafting mixture, wherein:

[0022] The step of described grafting mixture preparation is:

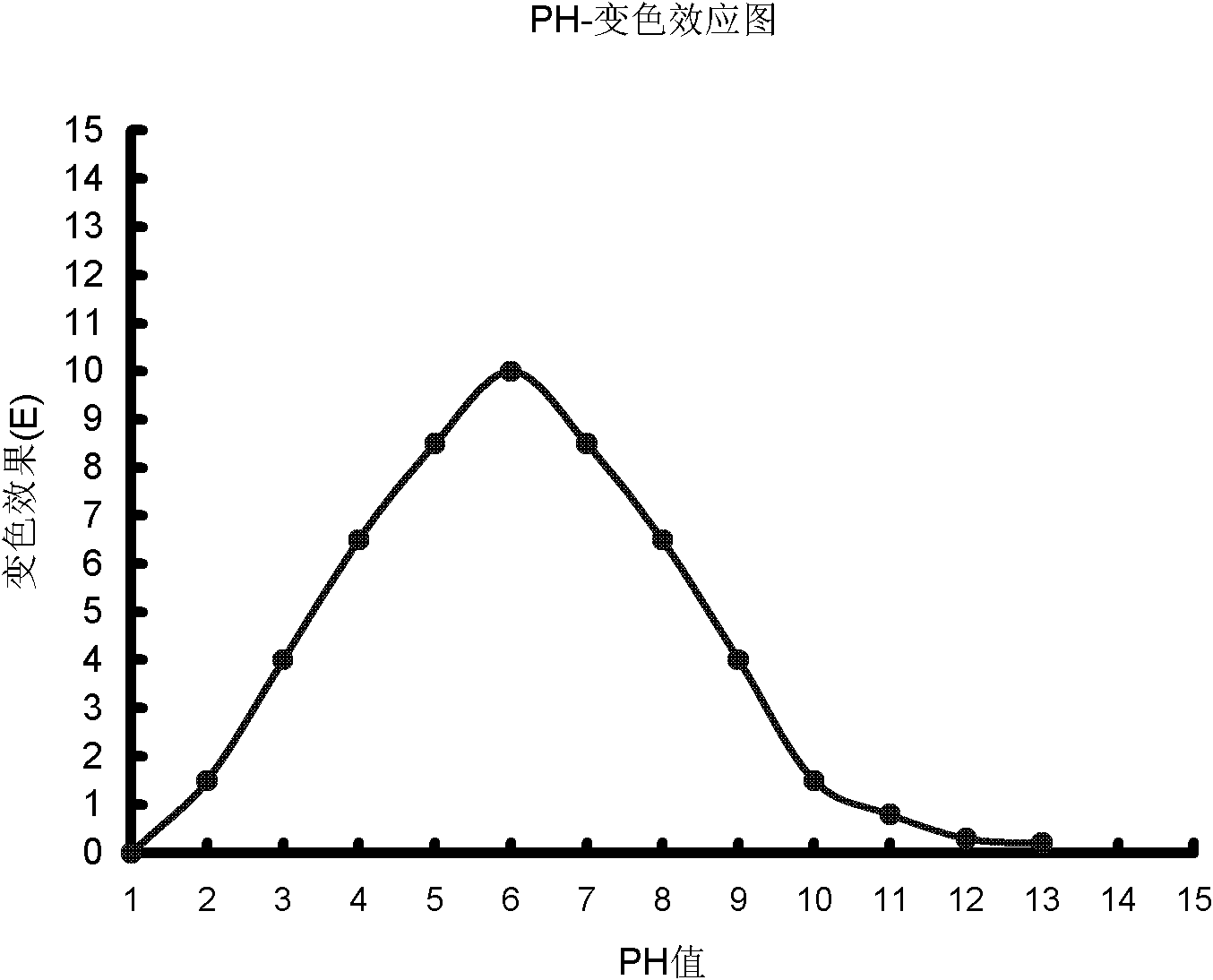

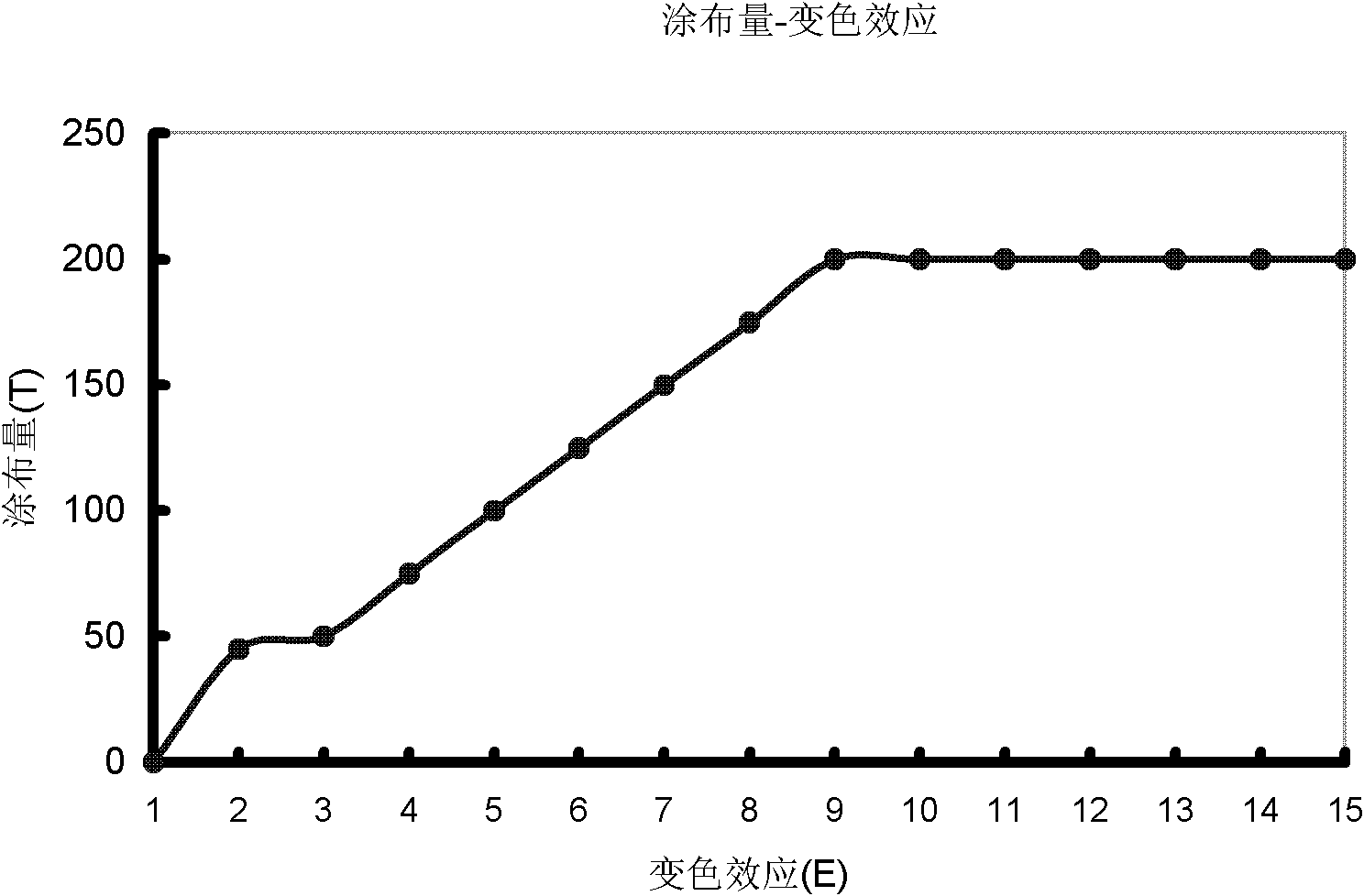

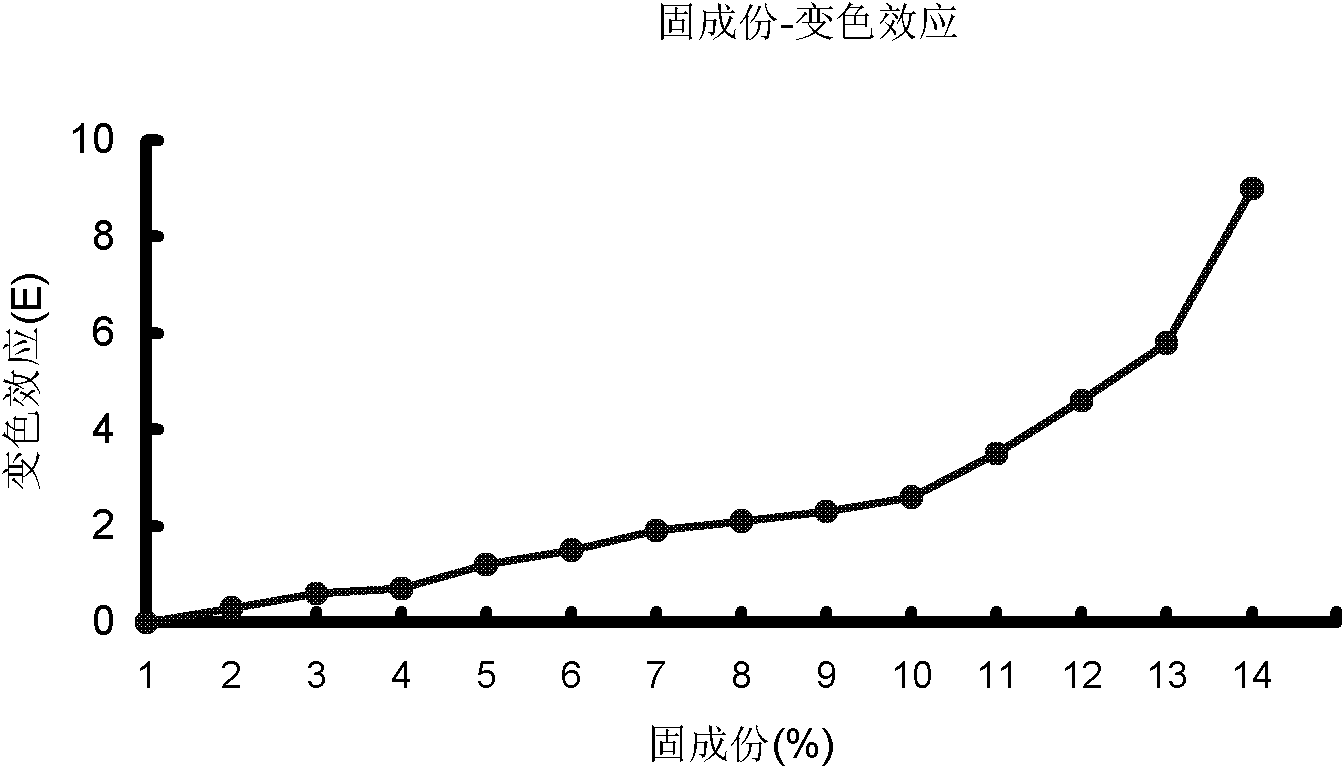

[0023] Dissolve the main carrier polyurethane in a non-toxic organic solvent, slowly stir the organic solvent, and add heat-sensitive discoloration microcapsules at the same time to obtain a pH value of 6-7, a solid content of 11%-15%, and a viscosity of 3500CPS-4500CPS The grafting mixture;

[0024] The step of coating transfer of the grafting mixture comprises:

[0025] Step a: coating the above-mentioned grafting mixture on one side of the release paper, baking the release paper at a temperature of 110°C-220°C, and drying the coated grafting mixture;

[0026] Step b: apply the adhesive to the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com