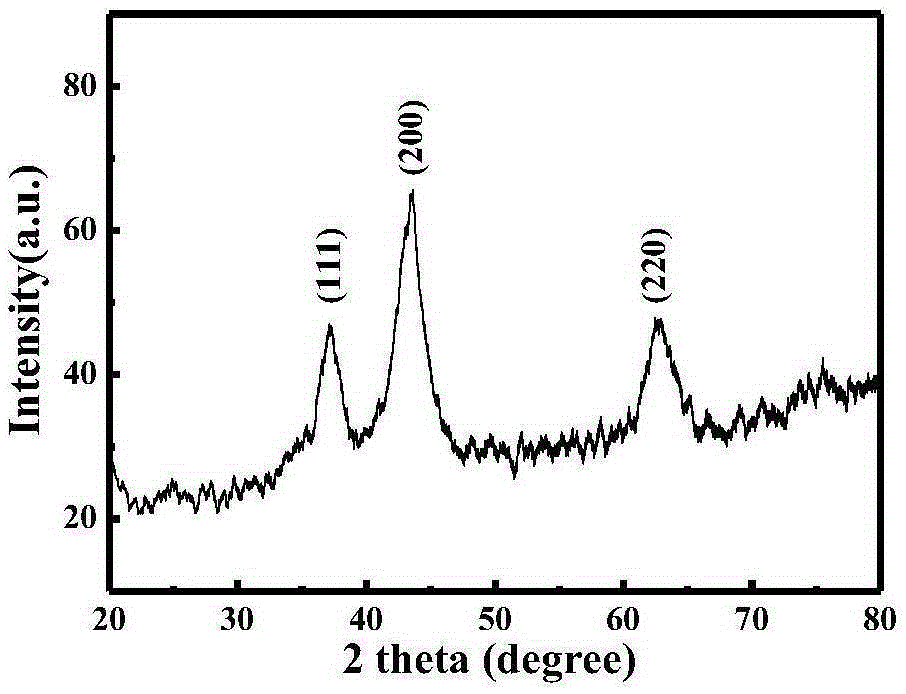

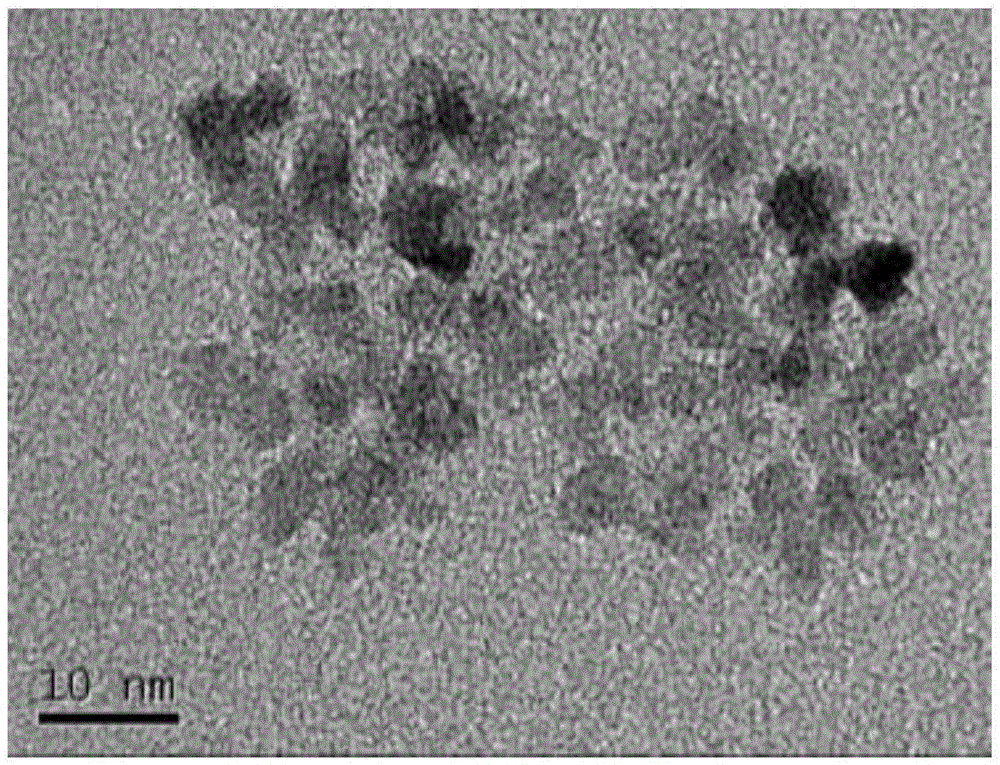

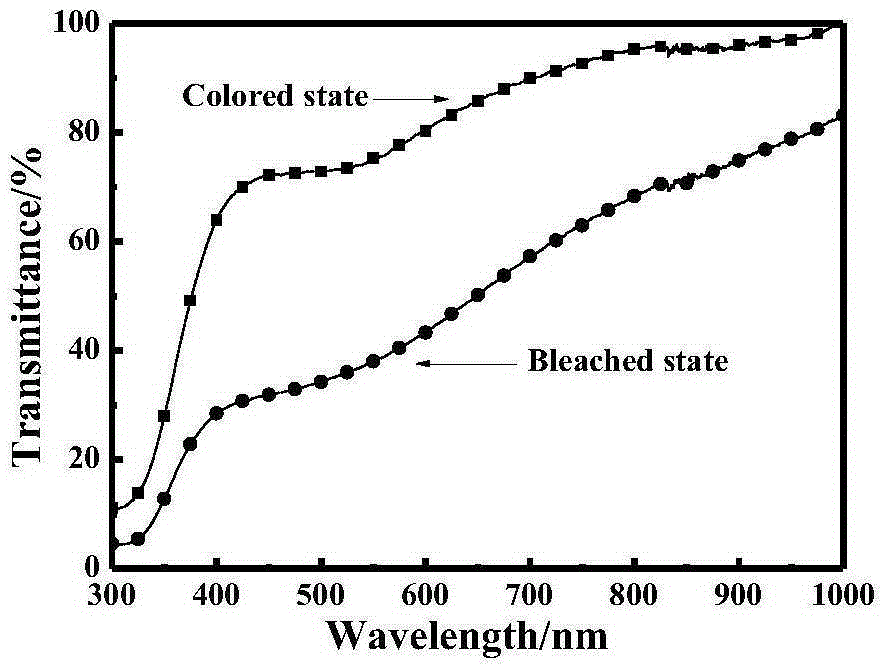

Making method of NiO nano-crystalline electrochromic film

An electrochromic and nanocrystalline technology, applied in the field of functional materials, can solve the problems of difficult film formation and shape control, and achieve good color changing effect, easy operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Measure 25ml of oleylamine and pour it into a three-necked flask, heat it to 180℃ and keep it for half an hour; weigh 1mmol of nickel nitrate and dissolve it in 5ml of methanol, and add 1ml of oleic acid after it is completely dissolved.

[0026] 2. Inject the above-prepared methanol solution into oleylamine at 180°C. The injecting process should be fast. Raise the temperature to 300°C for one hour; then cool the solution to room temperature, add 50ml acetone to precipitate the product, and centrifuge (10,000 revolutions per minute, 10 minutes) separation and drying to obtain NiO nanocrystalline powder.

[0027] 3. Take 20mg of NiO nanocrystalline powder and place it in 10ml of n-hexane, ultrasonically disperse for 0.5 hours and then fully stir to obtain NiO nanocrystalline ink, the stirring time is 2h.

[0028] 4. Wash the ITO conductive glass ultrasonically with ionized water, acetone and ethanol successively, the ultrasonic washing time is 1h each. After the washed ITO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com