Preparation of visible light response composite cuprate photocatalysis material and application thereof

A composite light and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrogen production, etc., can solve problems such as photocorrosion, short service life, and low hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

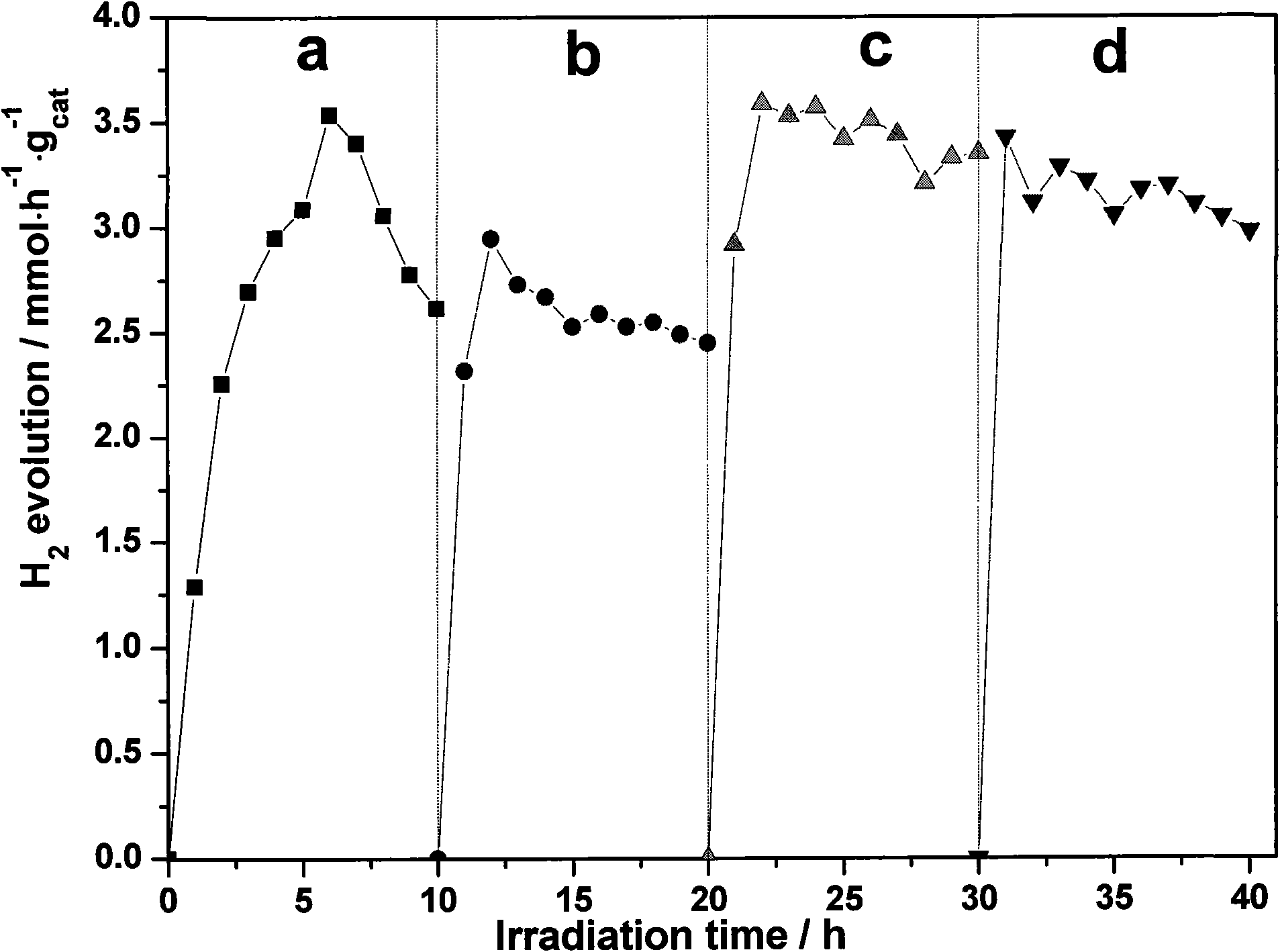

[0013] Weigh 0.01mol copper nitrate and dissolve it in 100mL distilled water to prepare 0.1mol L -1 copper nitrate solution. Slowly add each 0.01mol of ferric nitrate and cobalt nitrate into the above-mentioned copper nitrate solution to obtain CuFeCo(NO 3 ) 8 solution. Then in the freshly prepared CuFeCo(NO 3 ) 8 Add 100mL of 0.6mol·L dropwise to the solution -1 citric acid solution to obtain a transparent sol, continue heating in a water bath at 80°C to obtain a sol, then transfer to an oven, dry at 130°C for 3 hours to obtain a precursor, and finally calcinate at 800°C for 2 hours to obtain a copper ferrite-cobaltate composite Photocatalyst (CuCoFeO 4 ). 50mmol·L -1 Oxalic acid is the electron donor, and the catalyst concentration is 1.0g L -1 , the photocatalytic hydrogen production experiment was carried out under the condition of simulating sunlight excitation, and the average hydrogen production rate was 2.46mmol·h -1 g cat -1 . Continuous experiments show ...

Embodiment 2

[0015] Weigh 0.01mol copper nitrate and dissolve it in 100mL distilled water to prepare 0.1mol L -1 copper nitrate solution. Slowly add 0.001mol of yttrium nitrate, 0.009mol of iron nitrate and 0.010mol of cobalt nitrate into the copper nitrate solution obtained above to obtain yttrium-doped CuFeCo(NO 3 ) 8 solution. Then, the newly prepared yttrium-doped CuFeCo(NO 3 ) 8 Add 100mL of 0.6mol·L dropwise to the solution -1 citric acid solution to obtain a transparent sol, continue heating in a water bath at 80°C to obtain a sol, then transfer to an oven, dry at 130°C for 3 hours to obtain a precursor, and finally calcinate at 800°C for 2 hours to obtain yttrium-doped copper ferrite-cobalt acid Copper composite photocatalyst (CuY 0.2 Fe 1.8 o 4 -CuCo 2 o 4 ). 50mmol·L -1 Oxalic acid is the electron donor, and the catalyst concentration is 1.0g L -1 , the photocatalytic hydrogen production experiment was carried out under the condition of simulating sunlight excitation...

Embodiment 3

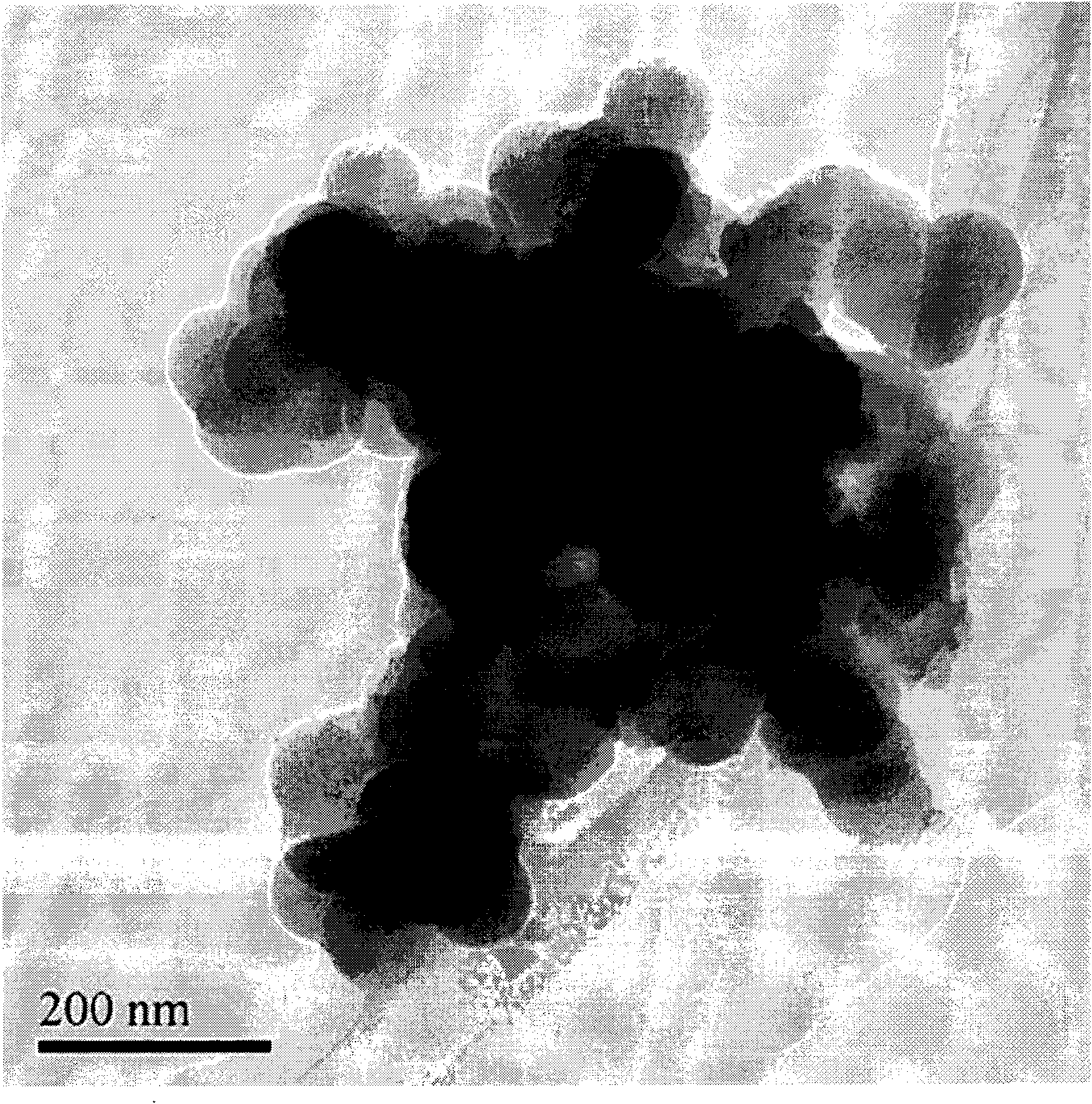

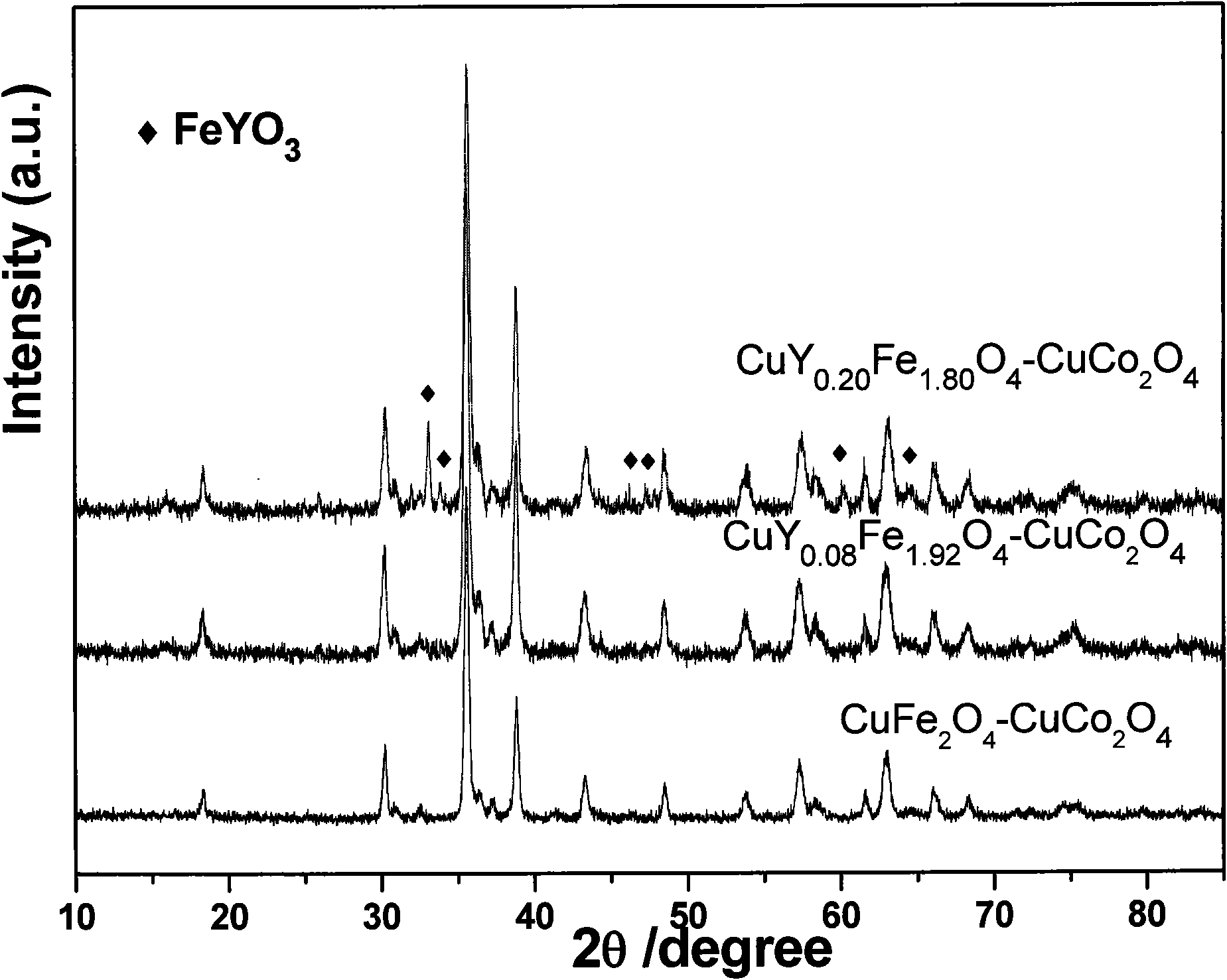

[0017] Weigh 0.01mol copper nitrate and dissolve it in 100mL distilled water to prepare 0.1mol L -1 copper nitrate solution. Slowly add 0.0004mol of yttrium nitrate, 0.0096mol of iron nitrate and 0.010mol of cobalt nitrate to the copper nitrate solution obtained above to obtain yttrium-doped CuFeCo(NO 3 ) 8 solution. Then, the newly prepared yttrium-doped CuFeCo(NO 3 ) 8 Add 100mL of 0.6mol·L dropwise to the solution -1citric acid solution to obtain a transparent sol, continue heating in a water bath at 80°C to obtain a sol, then transfer to an oven, dry at 130°C for 3 hours to obtain a precursor, and finally calcinate at 800°C for 2 hours to obtain yttrium-doped copper ferrite-cobalt acid Copper composite photocatalyst (CuY 0.08 Fe 1.92 o 4 -CuCo 2 o 4 ) (The TEM spectrum of the sample is shown in figure 1 , the XRD pattern of the sample is shown in figure 2 ). 50mmol·L -1 Oxalic acid is the electron donor, and the catalyst concentration is 1.0g L -1 , the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com