Preparation method and application of praseodymium cuprate nano absorbing material

A nano-adsorption material, praseodymium cuprate technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of limiting the production and application of praseodymium cuprate, low purity of praseodymium cuprate, unstable performance, etc., to achieve Conducive to the effect of nanometerization, good dispersion and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

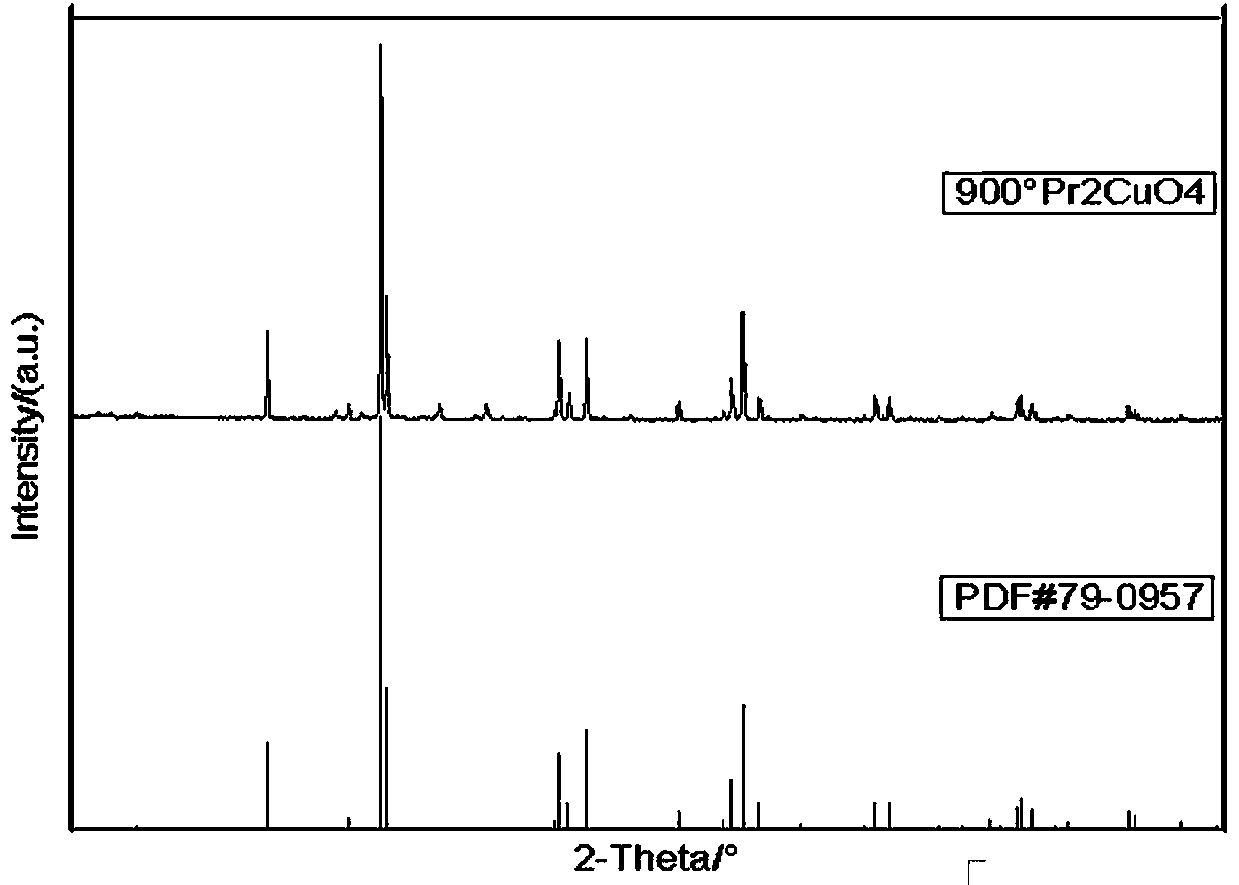

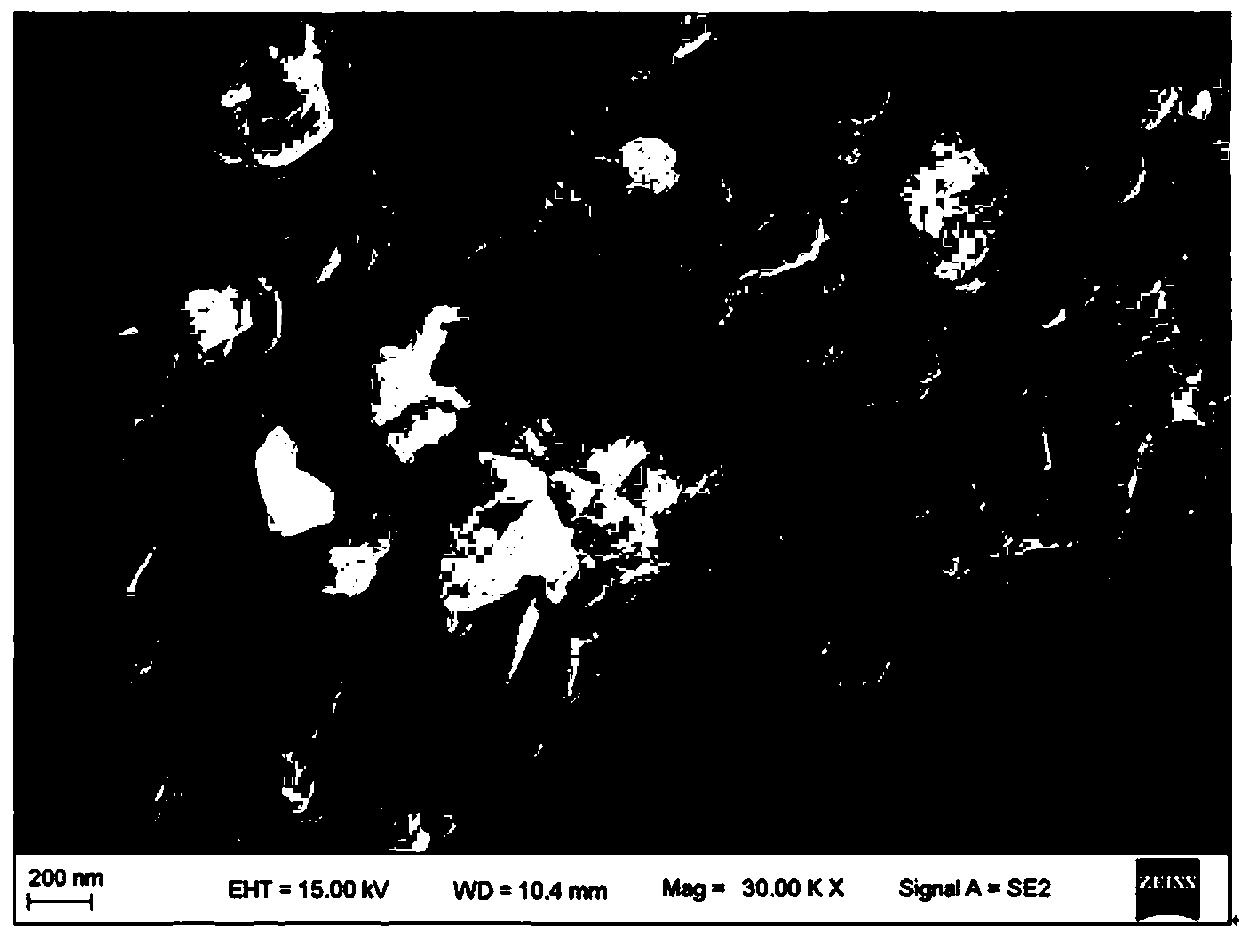

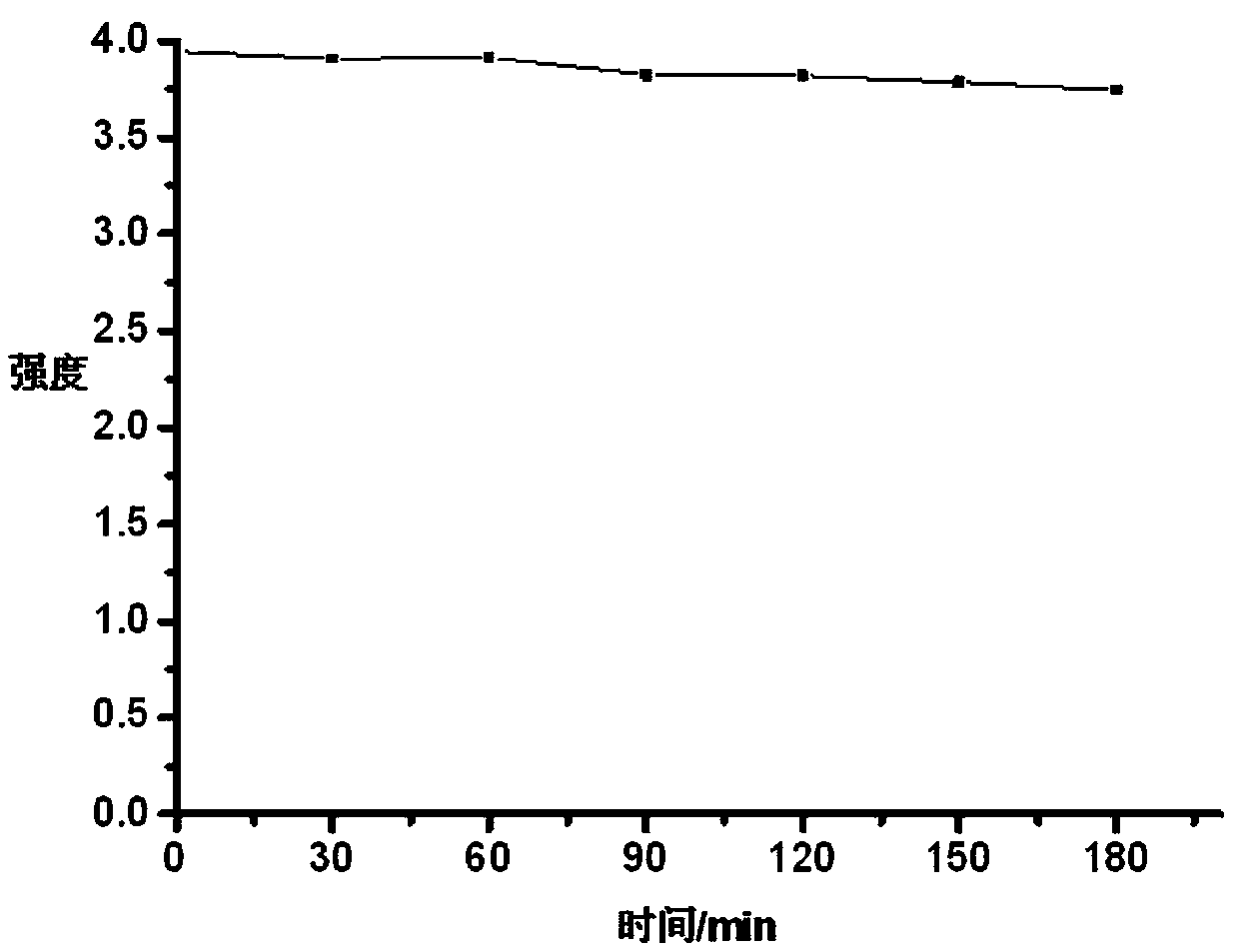

[0031] The preparation method of praseodymium cuprate nano-adsorption material, comprising the following steps: according to praseodymium cuprate Pr 2 CuO 4 In the stoichiometric ratio of Cu and Pr, weigh 5 mmol copper acetate and 10 mmol praseodymium acetate, dissolve in deionized water, and the volume dosage of deionized water is 4 times the total molar mass of copper acetate and praseodymium acetate, and mechanically stir until completely dissolved, to obtain Solution A; take by weighing 30mmol ammonia water and 20mmol dimethylglyoxime and dissolve in the mixed solution of 200mmol ethanol and water, stir mechanically until completely dissolved, control the pH value of the solution to be 10, obtain solution B; slowly pour solution B into solution A , add 2g polyethylene glycol 1000, stir magnetically for 1h (rotor speed is 800r / min) to obtain solution C; use improved electrospinning to prepare composites with nanometer diameters. During the preparation process, in the existi...

Embodiment 2

[0034] The preparation method of praseodymium cuprate nano-adsorption material, comprising the following steps: according to praseodymium cuprate Pr 2 CuO 4In the stoichiometric ratio of Cu and Pr, weigh 5 mmol copper nitrate and 10 mmol praseodymium nitrate, dissolve in deionized water, and the volume dosage of deionized water is 5 times the total molar mass of copper nitrate and praseodymium nitrate, and mechanically stir until completely dissolved to obtain Solution A; Weigh 35 mmol triethylamine and dissolve it in a mixed solution of 200 mmol ethanol and water (without adding dimethylglyoxime dispersant), stir mechanically until completely dissolved, and control the pH of the solution to be 10 to obtain solution B; Slowly pour B into solution A, add 1 g of polyethylene glycol 2000, stir magnetically for 1 h (rotor speed is 800 r / min) to obtain solution C; leave solution C to stand without applying an electric field, until the phenomenon of solid-liquid separation occurs, t...

Embodiment 3

[0037] The preparation method of praseodymium cuprate nano-adsorption material, comprising the following steps: according to praseodymium cuprate Pr 2 CuO 4 In the stoichiometric ratio of Cu and Pr, weigh 5 mmol copper nitrate and 10 mmol praseodymium nitrate, dissolve in deionized water, and the volume dosage of deionized water is 5 times the total molar mass of copper nitrate and praseodymium nitrate, and mechanically stir until completely dissolved to obtain Solution A; Weigh 30mmol of ammonia water and 20mmol of dimethylglyoxime and dissolve in a mixed solution of 200mmol of ethanol and water, mechanically stir until completely dissolved to obtain solution B; Pour solution B into solution A slowly, add 1g polyethylene glycol 2000, magnetic stirring for 1 h (rotor speed is 800 r / min), the pH value of the solution is controlled to 10.5, and solution C is obtained; the composite filaments with nanometer diameter are prepared by improved electrospinning. On the basis that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com