Preparation method of nano copper powder

A technology of nano copper powder and copper oxide powder, which is applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of lack of nano copper powder, difficulty in preparing nano copper powder with uniform particle size, etc. Low content and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

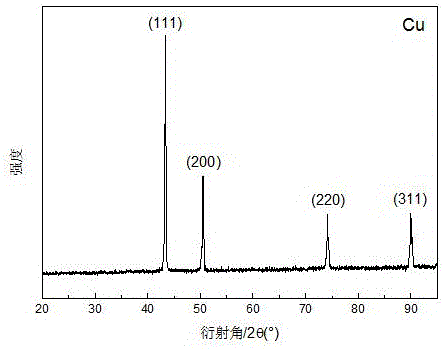

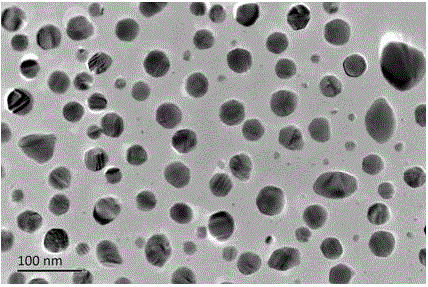

[0021] The preparation of nano-copper powder should be carried out according to the following steps: Accurately weigh 1.00kg of copper oxide powder (CuO) and 1.41kg of calcium oxide powder (CaO) according to the molar ratio of 1:2, and dry-mill in a planetary ball mill for 4h, evenly After mixing, they were placed in a tubular atmosphere furnace and calcined at 950 °C for 3 h under an oxygen atmosphere to obtain calcium cuprate (Ca 2 CuO 3 ) powder; the calcium cuprate powder was heated to 350 °C for 120 min in a hydrogen flow of 1.5 L / min and reduced for 120 min, and then the reduced product was washed four times with a dilute hydrochloric acid solution (10%) containing polyvinylpyrrolidone (PVP), and then used The reduction product was washed three times with absolute ethanol, and the product was dried to obtain nano-copper powder.

Embodiment 2

[0023] To prepare nano-copper powder, the following steps should be followed: Accurately weigh 1.00 kg of copper oxide powder (CuO) and 1.76 kg of calcium oxide powder (CaO) according to the molar ratio of 1:2.5, and dry-mill them in a planetary ball mill for 4 hours. After mixing, put it in a tube atmosphere furnace, and calcined at 950 °C for 3 hours in the atmosphere to obtain calcium cuprate (Ca 2 CuO 3 ) powder; the calcium cuprate powder was heated to 400°C for 120 min in a hydrogen flow of 1.5 L / min and reduced for 120 min, and then the reduced product was washed four times with dilute hydrochloric acid solution (10%) containing polyvinylpyrrolidone (PVP), and then used The reduction product was washed three times with absolute ethanol, and the product was dried to obtain nano-copper powder.

Embodiment 3

[0025] To prepare nano-copper powder, the following steps should be followed: Accurately weigh 1.00kg of copper oxide powder (CuO) and 1.76kg of calcium oxide powder (CaO) according to the molar ratio of 1:2.5, and dry-mill them in a planetary ball mill for 4 hours to evenly After mixing, place it in a tubular atmosphere furnace and calcinate at 1050°C for 3 hours under an argon atmosphere to obtain calcium cuprate (Ca 2 CuO 3 ) powder; the calcium cuprate powder was heated to 450°C for 90 min in a hydrogen flow of 2 L / min and reduced for 90 min, and then the reduced product was washed four times with a dilute hydrochloric acid solution (20%) containing polyethylene glycol (PEG), and then The reduction product was washed three times with absolute ethanol, and the product was dried to obtain nanometer copper powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com