Rapid solid-state reaction of oxides with ultraviolet radiation

A technology of oxides and ultraviolet light, applied in oxide conductors, copper compounds, inorganic chemistry, etc., can solve problems such as poor quality of superconductor materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

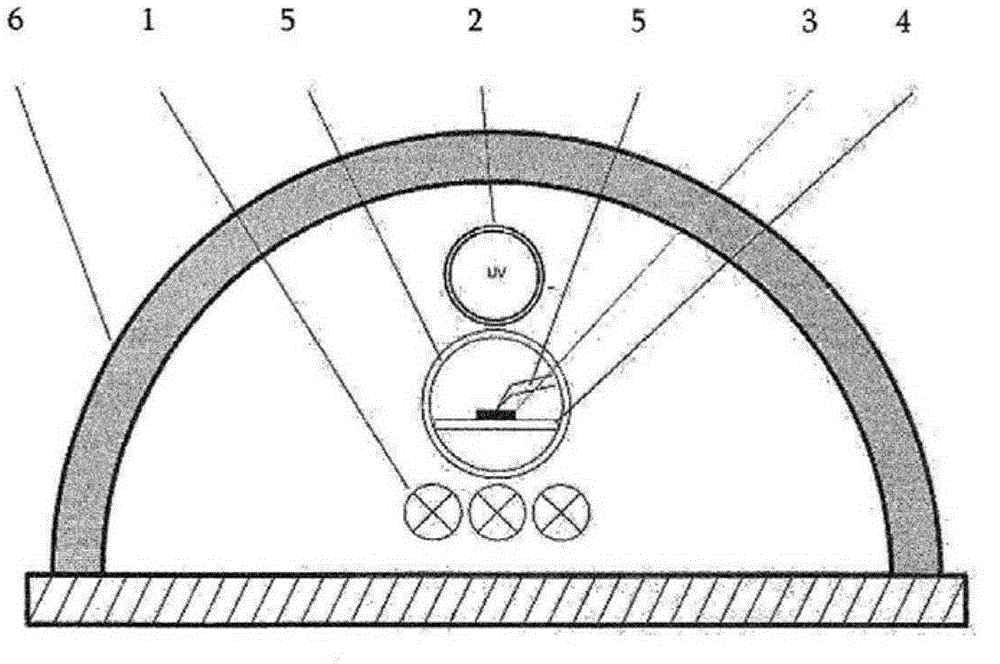

Method used

Image

Examples

Embodiment

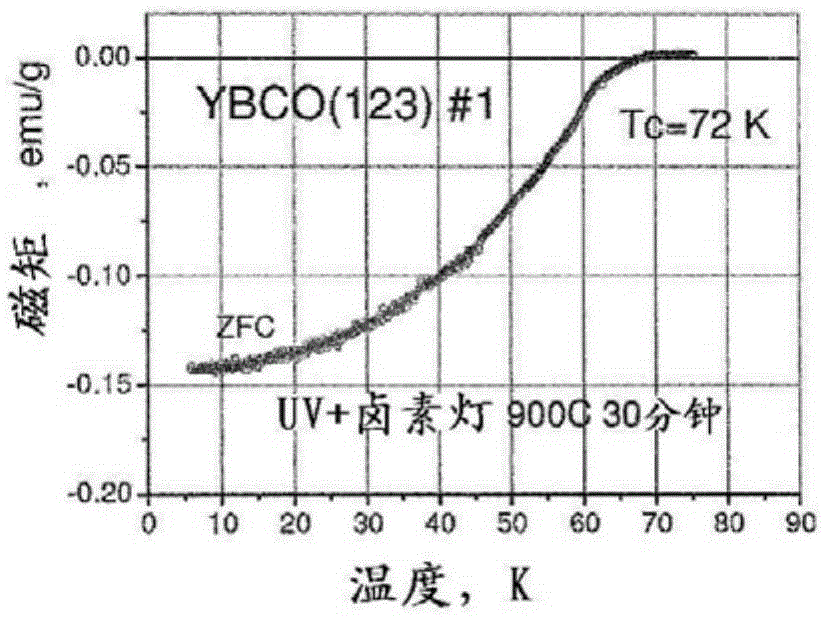

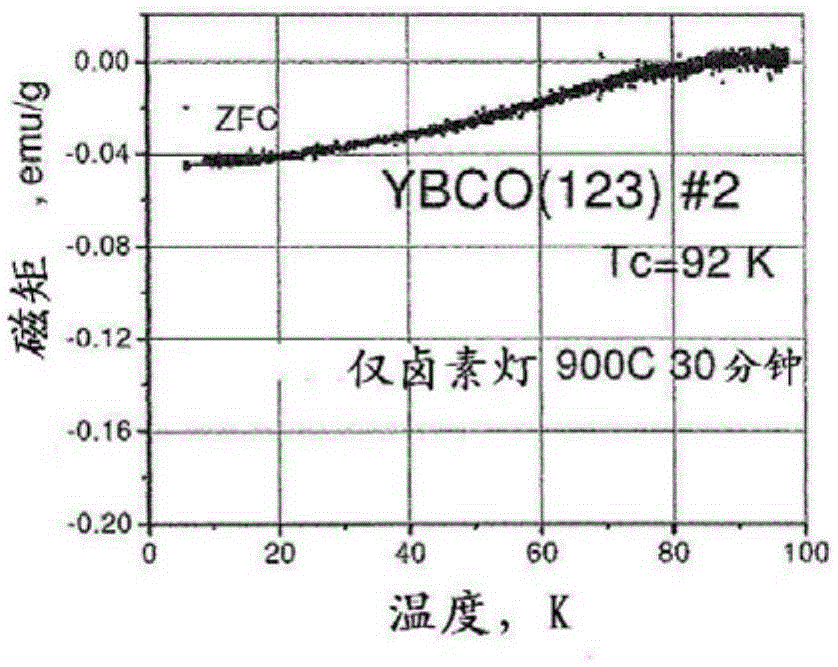

[0072] Example: high temperature superconductor YBa 2 Cu 3 o 7-x Synthesis

[0073] At least 99.99% pure La 2 o 3 、BaCO 3 and CuO in a stoichiometric ratio were thoroughly mixed in an agate mortar to make a powder mixture. Hereinafter, the powder mixture was compressed into pellets with a diameter of about 12 mm and a thickness of about 0.4 mm to 1 mm with a pressure of 5 tons. These pellets or samples were then irradiated under different conditions by means of the above-mentioned apparatus.

[0074] Sample #1 was irradiated by both UV and halogen lamps at 900 degrees Celsius for about 30 minutes. Sample #2 was irradiated by halogen lamp only at 900 degrees Celsius for about 30 minutes. Control Sample #3 was inserted into a conventional oven (which had been preheated to approximately 900 degrees Celsius) and the sample was removed from the oven after 30 minutes. All reactions with Sample #1, Sample #2 and Sample #3 were performed in air.

[0075] A black ceramic samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com