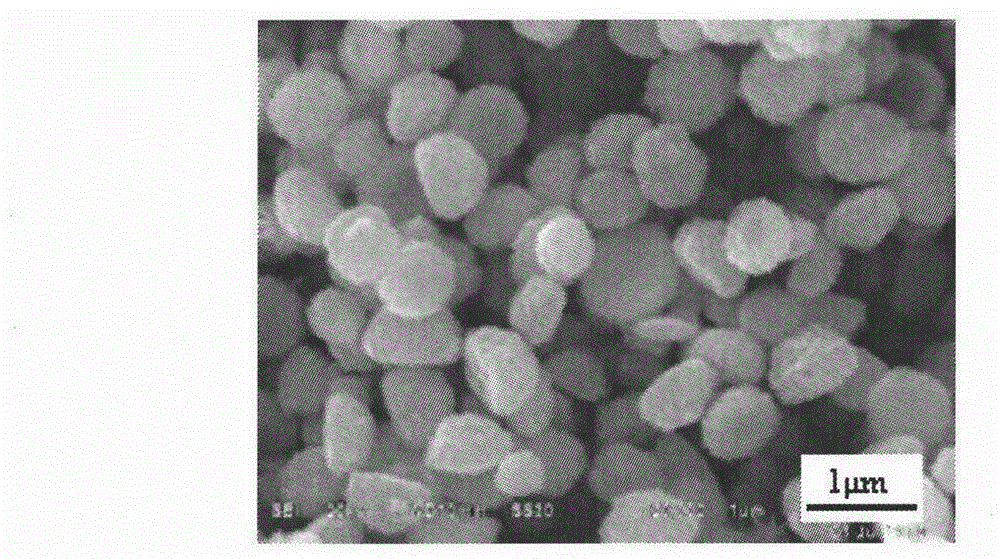

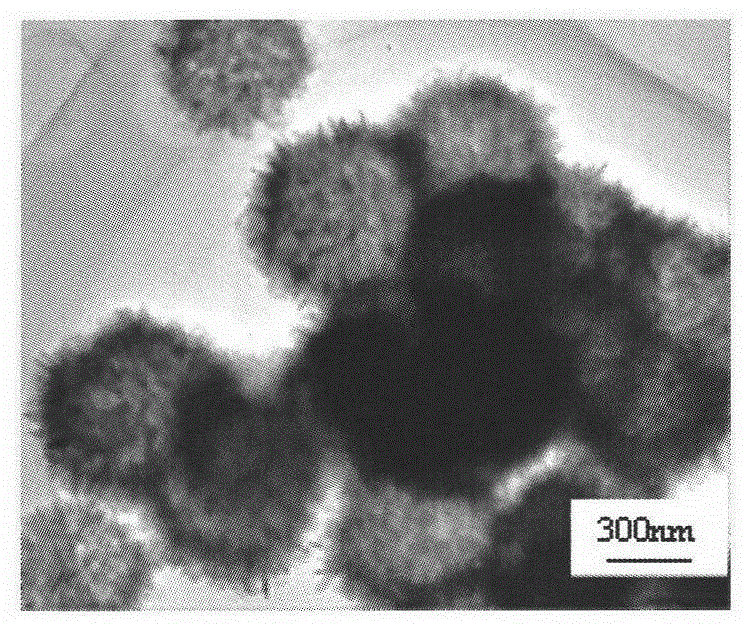

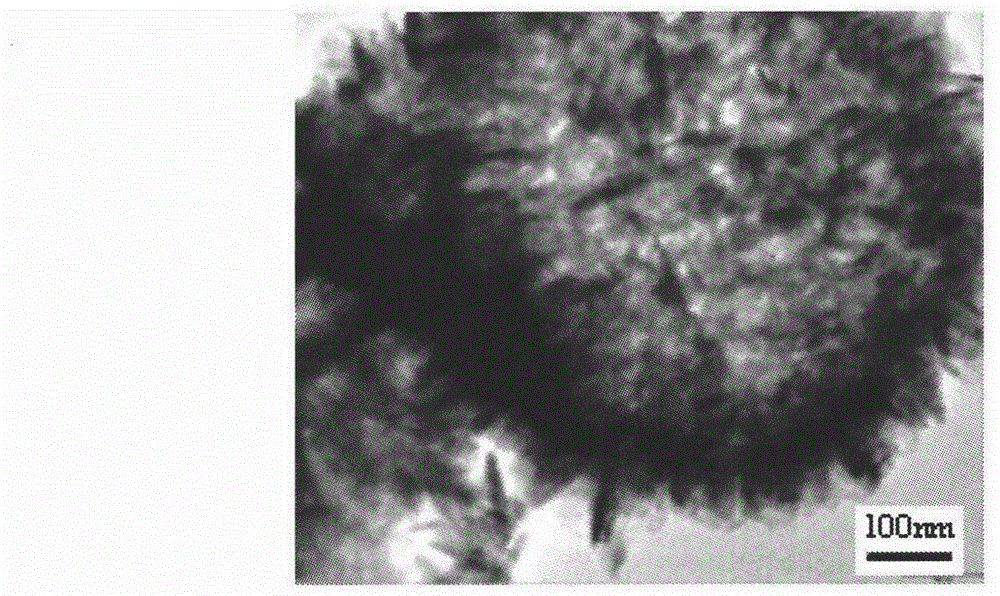

Preparation method for chestnut-shaped copper sulphide hollow micron sphere composed of nanosheets

A nano-sheet, copper sulfide technology, applied in copper sulfide and other directions, to achieve the effect of high specific surface free energy, less agglomeration and damage, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 8.52g CuCl 2 2H 2 Dissolve O with deionized water, add 6.69mL of ethylenediamine (en) copper chloride and ethylenediamine, the ratio of the amount of copper chloride to ethylenediamine is 1:2, transfer to a 100mL volumetric flask, and dilute to 100mL with deionized water 0.5mol / L[Cu(en) 2 ] 2+ solution.

[0031] (2) Mix 2.26mL octylphenol polyoxyethylene (9) ether (Triton X-100), 2.08mL n-hexanol and 35mL cyclohexane with 2mL 0.5mol / L [Cu(en) 2 ] 2+ The solution is mixed (ω=30, P=4.5), and the volume of cyclohexane is 8.1 times of the volume of octylphenol polyoxyethylene (9) ether and n-hexanol. Heating to 50°C, and stirring vigorously for 10 minutes to obtain a uniform [Cu(en) 2 ] 2+ inverse microemulsion. Then, add 0.18mL CS to the inverse microemulsion 2 (CS 2 The amount of the substance is 1.5 times that of ethylenediamine), and stirred evenly to obtain a mixed solution. The mixture was injected into a Teflon-lined reactor, and reacted at 120°...

Embodiment 2

[0035] (1) Weigh 7.48g CuSO 4 ·5H 2 Dissolve O with deionized water, add 5.02mL ethylenediamine (en) (the ratio of the amount of copper sulfate to ethylenediamine is 1:2.5), transfer to a 100mL volumetric flask, and dilute to 100mL 0.3mol with deionized water / L[Cu(en) 2 ] 2+ solution.

[0036] (2) Mix 3.39mL octylphenol polyoxyethylene (9) ether (Triton X-100), 2.04mL n-butanol and 32mL isooctane with 2mL 0.3mol / L [Cu(en) 2 ] 2+ The solutions are mixed (ω=20, P=4.0), and the volume of isooctane is 6 times of the sum of volumes of octylphenol polyoxyethylene (9) ether and n-butanol. Heating to 40°C, and stirring vigorously for 20 minutes to obtain a uniform [Cu(en) 2 ] 2+ inverse microemulsion. Then, add 0.13mL CS to the inverse microemulsion 2 (CS 2 The amount of the substance is 1.8 times that of ethylenediamine), stirred evenly to obtain a mixed solution. The mixed solution was injected into a polytetrafluoroethylene-lined reactor and reacted at 125°C for 6 hours...

Embodiment 3

[0040] (1) Weigh 19.32g Cu(NO 3 ) 2 ·3H 2 Dissolve O with deionized water, add 11.78mL ethylenediamine (en) (the ratio of the amount of copper nitrate to ethylenediamine is 1:2.2), transfer to a 100mL volumetric flask, and dilute to 100mL 0.8mol with deionized water / L[Cu(en) 2 ] 2+ solution.

[0041] (2) Mix 1.69mL of alkylphenol polyoxyethylene (10) ether (OP-10), 2.19mL of n-octanol and 39mL of n-octane with 2mL of 0.8mol / L [Cu(en) 2 ] 2+ The solutions are mixed (ω=40, P=5.0), and the volume of n-octane is 10 times of the sum of volumes of alkylphenol polyoxyethylene (10) ether and n-octanol. Heating to 45°C, and stirring vigorously for 30 minutes, a uniform [Cu(en)-containing 2 ] 2+ inverse microemulsion. Then, add 0.34mL CS to the inverse microemulsion 2 (CS 2 The amount of the substance is 1.6 times that of ethylenediamine), and stirred evenly to obtain a mixed solution. The mixed solution was injected into a Teflon-lined reactor, and reacted at 110° C. for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com