Preparation method of holmium cuprate nano powder

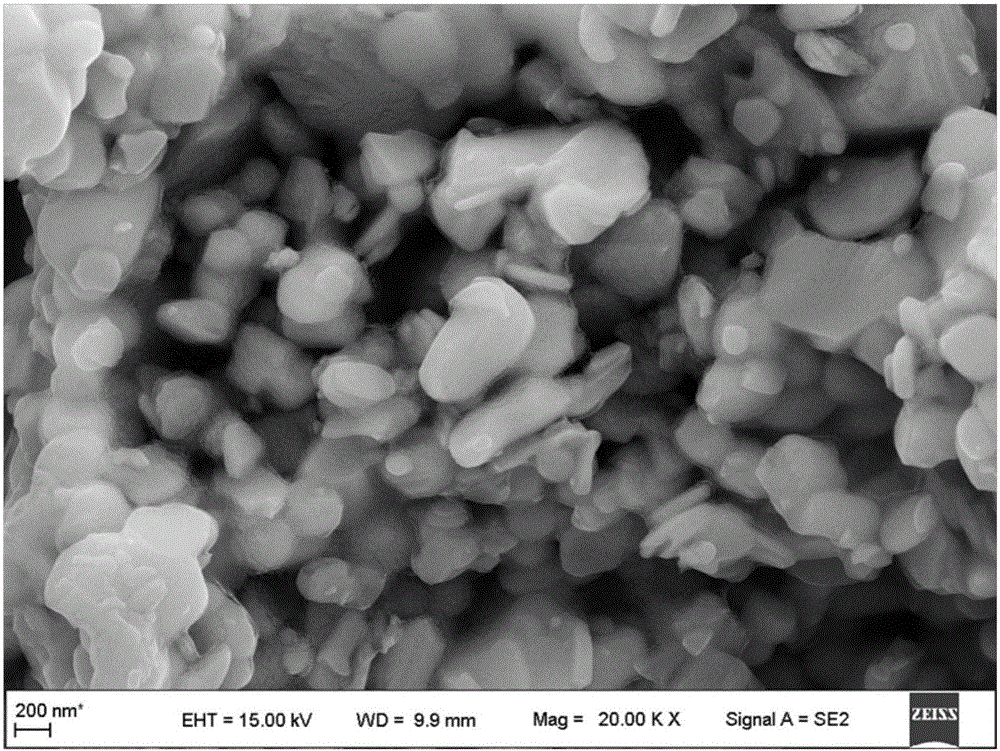

A nano-powder, holmium cuprate technology, applied in the field of preparation of holmium cuprate nano-powder, can solve the problem that the strict stoichiometric ratio of copper ions and rare earth ions cannot be solved, the purity of the sample is closely related to the properties, and the size of the nanometer cannot be reached. and other problems, to achieve the effect of regular particle shape, low cost and good particle consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Holmium Cuprate Ho 2 Cu 2 O 5 The preparation method of nano powder includes the following steps:

[0039] S1, follow Ho 2 Cu 2 O 5 In the stoichiometric ratio of Cu to Ho, weigh 2mmoL of copper nitrate and 2mmoL of holmium carbonate, and dissolve them in deionized water. The amount of deionized water is 4 times the total mass of copper nitrate and holmium carbonate. Mix well to prepare solution A;

[0040] S2. Weigh 4mmoL of dipicolinic acid and dissolve it in 30mL of methanol, add 6mmoL of NaOH to prepare solution B;

[0041] S3. Mix solution A and solution B, and magnetically stir for 1 hour to prepare solution C; slowly warm solution C to 30°C and keep it for 1 hour to precipitate precursor D; precursor D is a Cu-Ho complex precursor crystal;

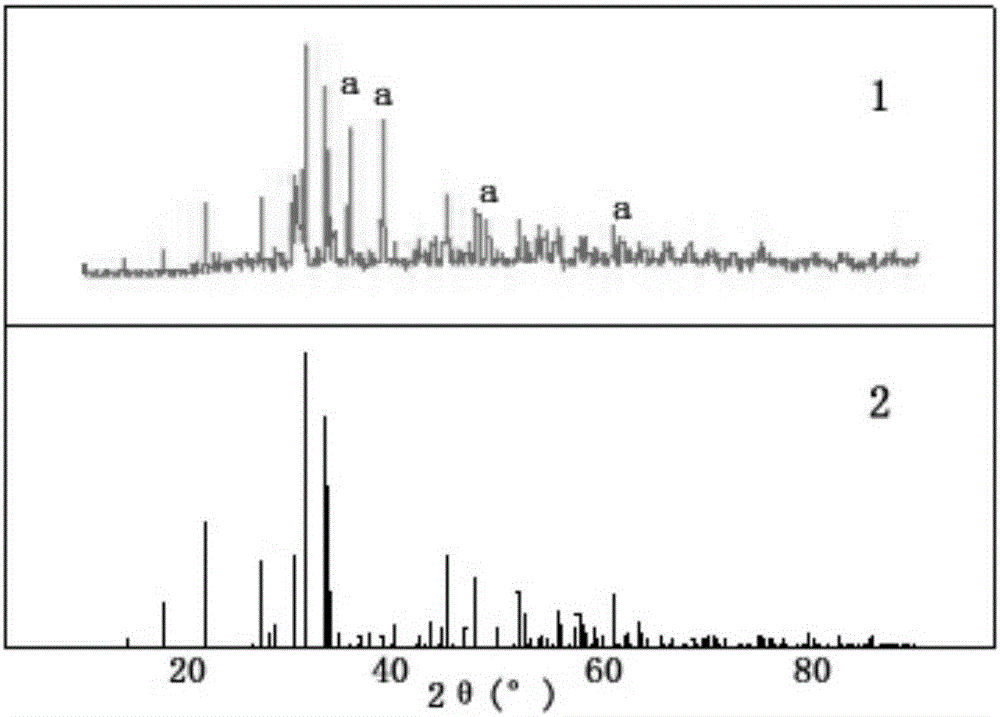

[0042] S4. Place the precursor D in a nitrogen atmosphere and sinter at 450°C for 6 hours, then cool to room temperature, and then calcinate in an air atmosphere at 800°C for 2 hours to obtain a calcined product;

[0043] S5. After the...

Embodiment 2

[0045] Holmium Cuprate Ho 2 Cu 2 O 5 The preparation method of nano powder includes the following steps:

[0046] S1, follow Ho 2 Cu 2 O 5 In the stoichiometric ratio of Cu to Ho, weigh 2mmoL of copper acetate and 2mmoL of holmium nitrate and dissolve them in deionized water. The amount of deionized water is 6 times the total mass of copper acetate and holmium nitrate. Mix well to prepare solution A;

[0047] S2. Weigh 8mmoL of pyridine tricarboxylic acid and dissolve it in 50mL of ethanol, add 24mmoL of KOH to prepare solution B;

[0048] S3. Mix solution A and solution B, and mechanically stir for 2 hours to prepare solution C; slowly warm solution C to 100°C and keep it for 1 hour to precipitate precursor D;

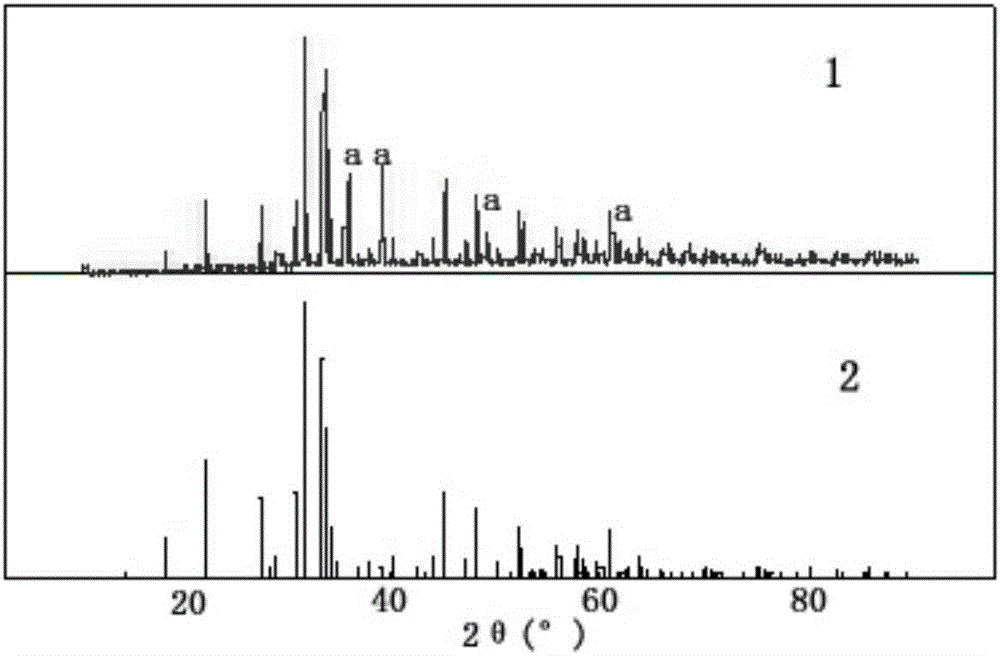

[0049] S4. Place the precursor D in an ammonia atmosphere, sinter at 550°C for 3 hours, then cool to room temperature, and then calcinate in an air atmosphere at 1100°C for 1 hour to obtain a calcined product;

[0050] S5. The calcined product is crushed, ground, passed through...

Embodiment 3

[0052] Holmium Cuprate Ho 2 Cu 2 O 5 The preparation method of nano powder includes the following steps:

[0053] S1, follow Ho 2 Cu 2 O 5 In the stoichiometric ratio of Cu to Ho, weigh 2mmoL of copper carbonate and 2mmoL of holmium acetate and dissolve them in deionized water. The amount of deionized water is 5 times the total mass of copper carbonate and holmium acetate. Mix well to prepare solution A;

[0054] S2. Weigh 6mmoL dipicolinic acid and dissolve it in 40mL propanol, add 12mmoL triethylamine to prepare solution B;

[0055] S3. Mix solution A and solution B, and magnetically stir for 1.5 hours to prepare solution C; slowly warm solution C to 60° C. and keep it for 1.5 hours to precipitate precursor D; precursor D is a Cu-Ho complex precursor crystal;

[0056] S4. Place the precursor D in a hydrogen atmosphere, sinter at 500°C for 4.5 hours, then cool to room temperature, and then calcinate in an air atmosphere at 1000°C for 1.5 hours to obtain a calcined product;

[0057] S5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com