Preparation method and application of neodymium cuprate nano-powder

A nano-powder, cupric acid technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low powder purity, limited popularization and application, particle agglomeration, etc., and achieves simple process and simple preparation process. Easy, high performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

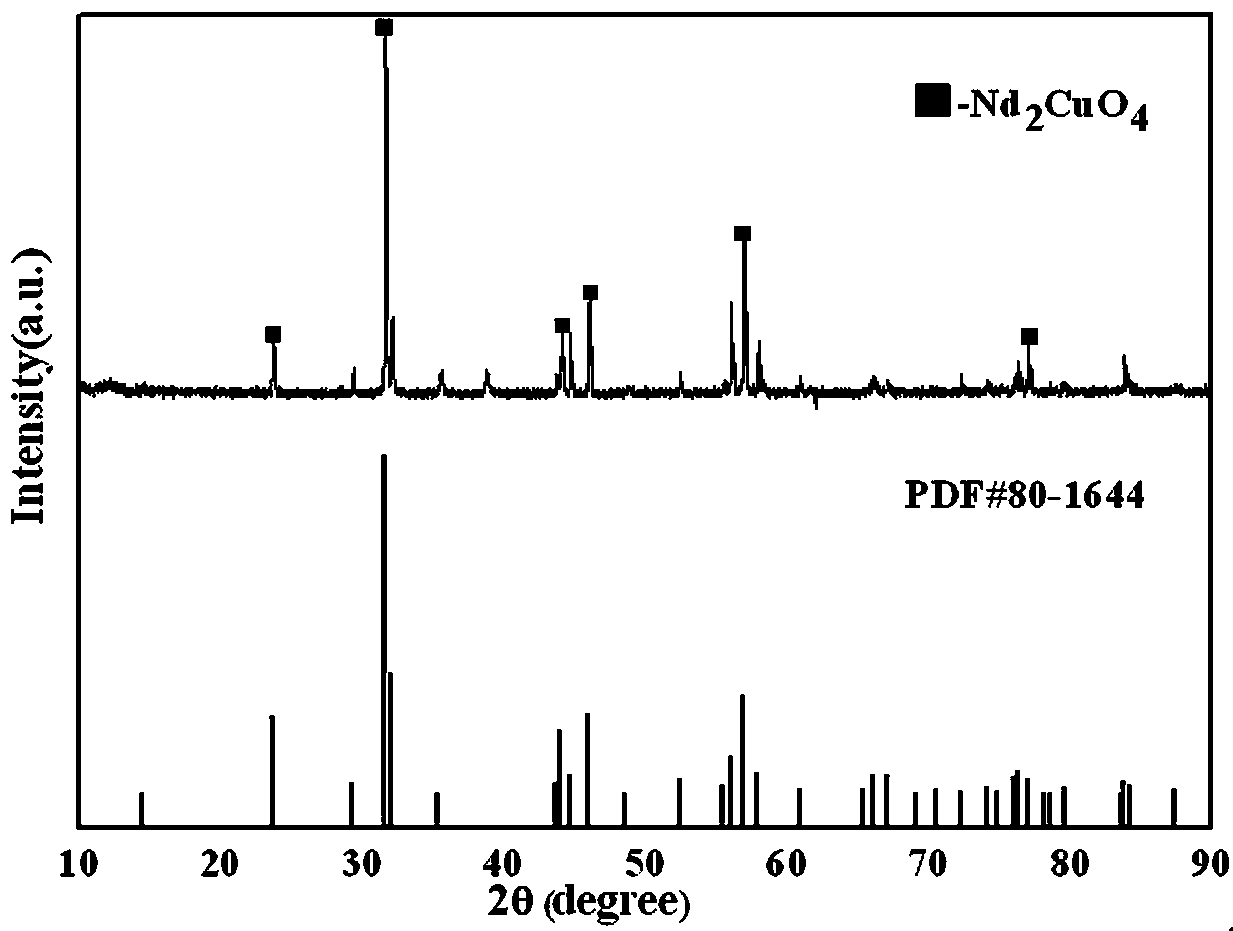

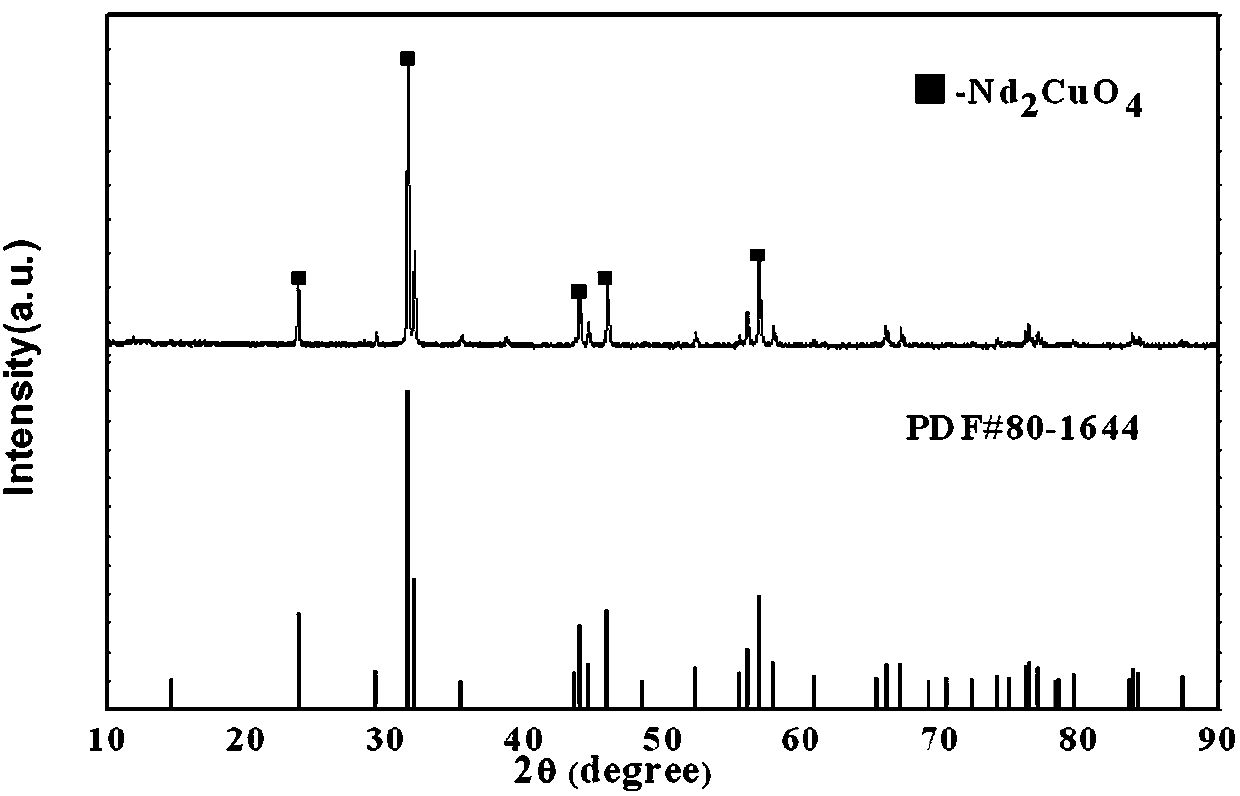

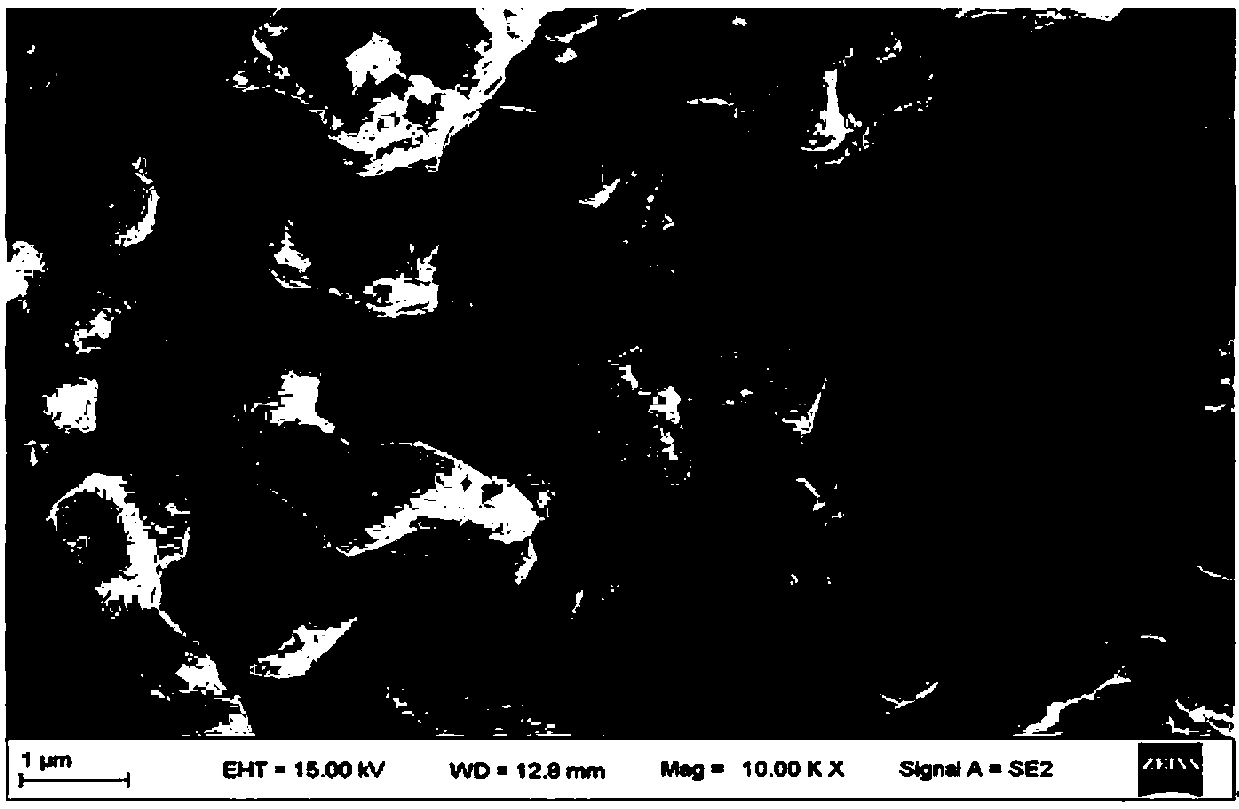

[0033] A preparation method for neodymium cuprate nanopowder, comprising the following steps: according to neodymium cuprate (Nd 2 CuO 4 The stoichiometric ratio of Cu and Nd in ) weighed 2mmol copper acetate and 4mmol neodymium acetate and dissolved them in deionized water. Dissolve to obtain solution A; measure 4mmol of dimethylglyoxime and place it in a beaker, add 16mmol of deionized water, and mechanically stir at 500r / min until completely dissolved to obtain solution B; slowly pour solution B into solution A, 500r / min Stir mechanically until evenly mixed to obtain solution C; heat solution C at 60°C and stir magnetically at 500r / min until the solution becomes viscous, then put it in an oven at 80°C for 7 hours to obtain substance C; take out substance C and put Put it into the crucible, first heat up in a low-temperature furnace for 3 hours, sinter at 700°C, and keep warm for 4 hours, then put it in a high-temperature nitrogen furnace to heat up for 3 hours, sinter at 1...

Embodiment 2

[0036] A preparation method for neodymium cuprate nanopowder, comprising the following steps: according to neodymium cuprate (Nd 2 CuO 4 The stoichiometric ratio of Cu and Nd in ) weighs 2.5mmol copper carbonate and 5mmol neodymium nitrate and dissolves them in deionized water. Completely dissolve to obtain solution A; measure 5mmol of dimethylglyoxime and place it in a beaker, add 20mmol of deionized water, and mechanically stir at 900r / min until completely dissolved to obtain solution B; slowly pour solution B into solution A, 900r / min Min mechanically stirred until uniformly mixed to obtain solution C; heated solution C at 60°C and magnetically stirred at 900r / min until the solution became viscous, then put it in an oven at 90°C for 6 hours to obtain substance D; took substance D out Put it into a crucible, first heat up in a low-temperature furnace for 3 hours, sinter at 750°C, and keep warm for 4 hours, then put it in a high-temperature nitrogen furnace to heat up for 3 ...

Embodiment 3

[0039] A preparation method for neodymium cuprate nanopowder, comprising the following steps: according to neodymium cuprate (Nd 2 CuO 4 The stoichiometric ratio of Cu and Nd in ) weighed 2mmol of copper acetate and 4mmol of neodymium nitrate and dissolved them in deionized water. Dissolve to obtain solution A; measure 10mmol of dimethylglyoxime and place it in a beaker, add 45mmol of deionized water, and mechanically stir at 1000r / min until completely dissolved to obtain solution B; slowly pour solution B into solution A at 1000r / min Stir mechanically until evenly mixed to obtain solution C; heat solution C at 70°C and magnetically stir until the solution becomes viscous, then put it in an oven at 80°C for 6.5 hours to obtain substance D; take out substance D and put it in a crucible Inside, first heat up in a low-temperature furnace for 3.5 hours, sinter at 700°C, hold for 4 hours, then put it in a high-temperature furnace for 3.5 hours, sinter at 1000°C (without nitrogen),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com