Adsorption desulfurization additive, as well as preparation method and desulfurization system thereof

A technology for adsorption desulfurization and adsorbent, which is applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc. It can solve the problem that the desulfurization adsorbent bed cannot reach the material level, increase the wear and deactivation of the desulfurization adsorbent process, desulfurization adsorbent activity and stability decline, to achieve the effect of reducing adverse effects, improving stability, and reducing regeneration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

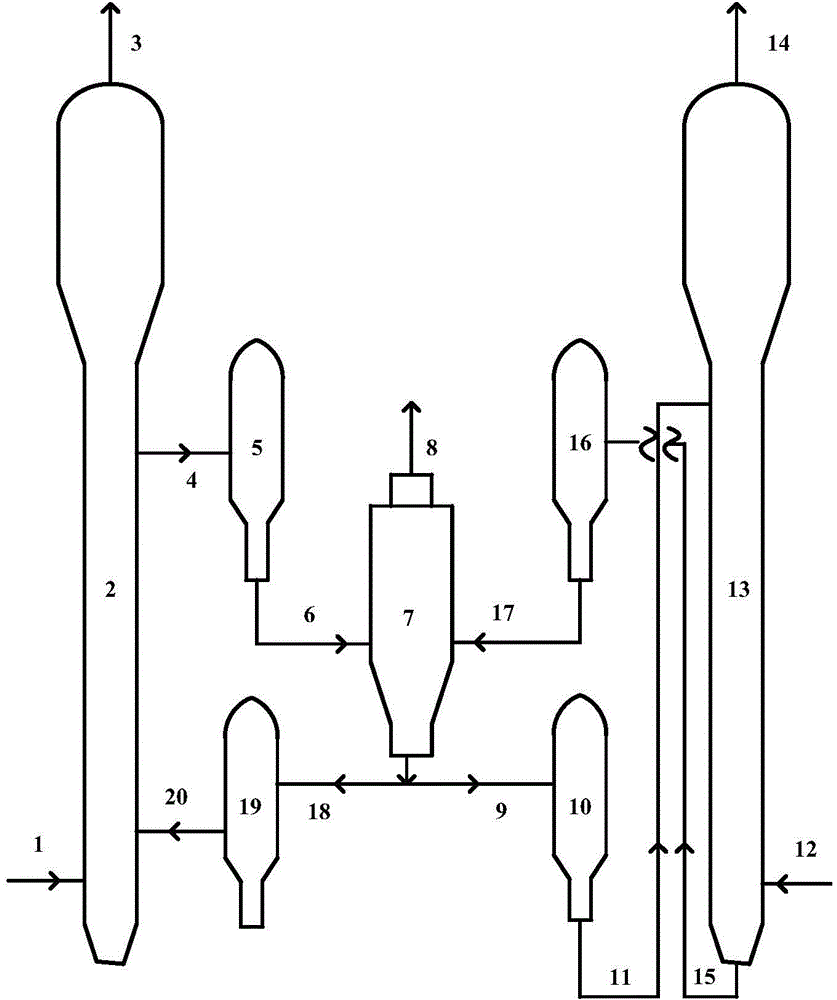

Image

Examples

preparation example Construction

[0026] The preparation method of adsorption desulfurization aid provided by the invention comprises the following steps:

[0027] (1) Forming, drying and roasting the slurry of alumina, silicon oxide and water to obtain the carrier of the adsorption desulfurization aid;

[0028] (2) loading metal oxide components on the adsorption desulfurization aid carrier, the metal oxide components are selected from sodium oxide, potassium oxide, magnesium oxide, calcium oxide, titanium oxide, vanadium oxide, chromium oxide, One or more of manganese oxide, iron oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide, cerium oxide, praseodymium oxide and neodymium oxide.

[0029] In the present invention, the amount of the adsorption desulfurization aid carrier and the metal oxide component is not particularly limited, and can be a conventional choice in the art, for example, based on the total weight of the adsorption desulfurization aid, the adsorption desulfurization aid The a...

preparation example 1

[0060] This preparation example is used to illustrate the adsorption desulfurization aid provided by the present invention and its preparation method.

[0061] Alumina (chemically pure, produced by Shandong Zibo Aluminum Factory, the same below) and silicon oxide (chemically pure, purchased from Shanghai Merrill Chemical Technology Co., Ltd., the same below) were mixed according to the mass ratio of 1:2, and then deionized Water is mixed and beaten to obtain a slurry with a solid content of 15% by weight, and the pH value of the slurry is adjusted with a solution of nitric acid (chemically pure, produced by Huantai County Shunxin Chemical Co., Ltd., the same below) with a volume concentration of 30% under stirring. To 5, continue to stir until a uniform sol is formed, and the sol is spray-dried and molded at a controlled tail gas temperature of 250°C and a spray pressure of 50 atmospheres to obtain microspherical solid particles. The prepared microspherical solid particles wer...

preparation example 2

[0063] This preparation example is used to illustrate the adsorption desulfurization aid provided by the present invention and its preparation method.

[0064] Aluminum oxide and silicon oxide are mixed according to the ratio of mass ratio 5:1, and then mixed with deionized water for beating to obtain a slurry with a solid content of 10% by weight, and the pH of the slurry is adjusted with a nitric acid solution with a volume concentration of 30%. Adjust the value to 2, and continue to stir until a uniform sol is formed. The sol is spray-dried and molded at a controlled tail gas temperature of 300°C and a spray pressure of 60 atmospheres to obtain microspherical solid particles. The prepared microspherical solid particles were dried at 120° C. for 2 hours, and then calcined at 700° C. for 0.5 hour to obtain adsorption desulfurization aid carrier particles with an average particle diameter of 100 μm. The pre-configured chromium nitrate aqueous solution with a mass concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com