Anticorrosive, wax-proof and high-temperature-resistant polyethylene tube for oil extraction and preparation method of polyethylene tube

A technology of high temperature resistant polyethylene and high density polyethylene, applied in the field of polyethylene lined pipes, can solve the problems of high cost and poor acid resistance of oil pumping pipes, and achieve the effect of improving rigidity, improving heat resistance and good acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

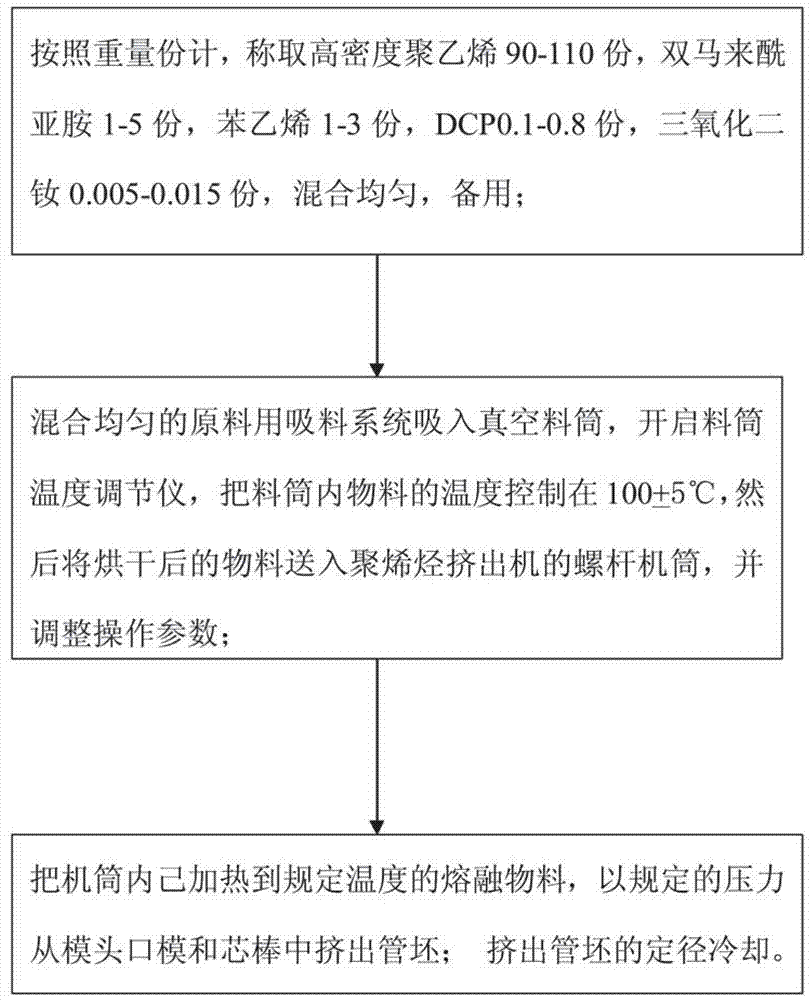

[0047]A preparation method for anti-corrosion, anti-wax deposition, and high-temperature-resistant polyethylene pipes for oil recovery, comprising the following steps:

[0048] 1) In parts by weight, weigh 100 parts of PE100 high-density polyethylene, 3 parts of bismaleimide, 1.5 parts of styrene, 0.3 part of DCP crosslinking agent, and 0.01 part of neodymium trioxide, mix well, and set aside;

[0049] 2) Inhale the uniformly mixed raw materials into the vacuum barrel with the suction system, turn on the barrel temperature regulator, control the temperature of the material in the barrel at 100°C, and then send the dried material into the polyolefin extruder Screw barrel; the polyolefin extruder adopts a gradual change type screw, and the screw compression ratio is 3.4:1;

[0050] 3) Adjust the parameters of the screw machine:

[0051] Adjust the temperature of each heating zone of the extruder barrel: Zone 1: 175°C; Zone 2: 203°C; Zone 3: 213°C; Zone 4: 213°C;

[0052] Adjus...

Embodiment 2

[0058] A preparation method for anti-corrosion, anti-wax deposition, and high-temperature-resistant polyethylene pipes for oil recovery, comprising the following steps:

[0059] 1) In parts by weight, weigh 90 parts of PE80 high-density polyethylene, 1 part of bismaleimide, 1 part of styrene, 0.1 part of DCP crosslinking agent, and 0.005 part of neodymium trioxide, mix well, and set aside;

[0060] 2) Inhale the uniformly mixed raw materials into the vacuum barrel with the suction system, turn on the barrel temperature regulator, control the temperature of the material in the barrel at 95°C, and then send the dried material into the polyolefin extruder Screw barrel; the polyolefin extruder adopts a gradual change type screw, and the screw compression ratio is 3.4:1;

[0061] 3) Adjust the parameters of the screw machine:

[0062] Adjust the temperature of each heating zone of the extruder barrel: Zone 1: 170°C; Zone 2: 200°C; Zone 3: 210°C; Zone 4: 210°C;

[0063] Adjust the...

Embodiment 3

[0069] A preparation method for anti-corrosion, anti-wax deposition, and high-temperature-resistant polyethylene pipes for oil recovery, comprising the following steps:

[0070] 1) In parts by weight, weigh 110 parts of PE100 high-density polyethylene, 5 parts of bismaleimide, 3 parts of styrene, 0.8 part of DCP crosslinking agent, and 0.015 parts of neodymium trioxide, mix well, and set aside;

[0071] 2) Inhale the uniformly mixed raw materials into the vacuum barrel with the suction system, turn on the barrel temperature regulator, control the temperature of the material in the barrel at 105°C, and then send the dried material into the polyolefin extruder Screw barrel; the polyolefin extruder adopts a gradual change type screw, and the screw compression ratio is 3.4:1;

[0072] 3) Adjust the parameters of the screw machine:

[0073] Adjust the temperature of each heating zone of the extruder barrel: Zone 1: 185°C; Zone 2: 205°C; Zone 3: 215°C; Zone 4: 215°C;

[0074] Adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com