Controllable dual-porous Ce/Zr composite oxide, and preparation method and application thereof

A composite oxide, double-channel technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as inability to meet practical application needs and deficiencies. To achieve the effect of excellent loading performance and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

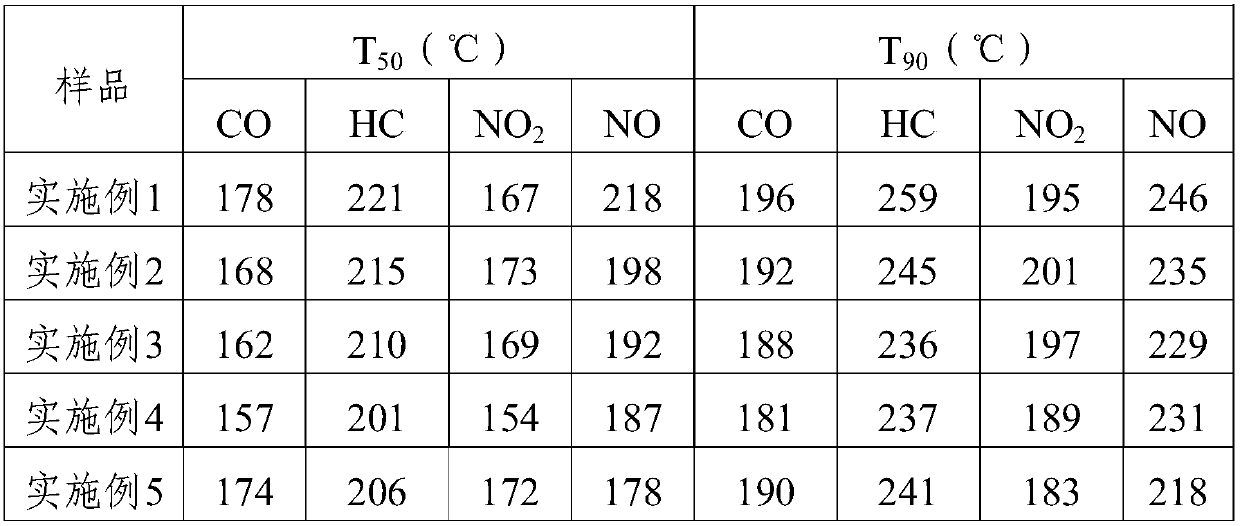

Embodiment 1

[0071] This embodiment provides a composite oxide based on cerium oxide, zirconium oxide, lanthanum oxide, and yttrium oxide and a preparation method thereof.

[0072] Among them: cerium oxide, zirconium oxide, lanthanum oxide, and yttrium oxide are recorded in proportions by weight: 25%, 60%, 4%, and 11%.

[0073] The preparation steps are as follows:

[0074] In the first beaker, dissolve 140g of cerium ammonium nitrate corresponding to cerium oxide in 500ml of deionized water, add 38.9g of EDTA, and stir for 1h; in the second beaker, add 336g of zirconium nitrate corresponding to zirconia and 85.4g of EDTA, and use 1000ml Dissolve in deionized water and stir for 1 hour; in the third beaker, dissolve 22.4g of lanthanum nitrate corresponding to lanthanum oxide and 61.6g of yttrium nitrate corresponding to yttrium oxide with 1000ml of deionized water, and stir the solution until clear.

[0075] Mix the solutions in the three beakers, stir until clear, and adjust the pH to 1.5...

Embodiment 2

[0080] This embodiment provides a composite oxide based on cerium oxide, zirconium oxide, lanthanum oxide, and praseodymium oxide and a preparation method thereof.

[0081] Among them: cerium oxide, zirconium oxide, lanthanum oxide, and praseodymium oxide are recorded in proportions by weight: 40%, 50%, 4%, and 6%.

[0082] The preparation steps are as follows:

[0083] In the first beaker, dissolve 224g of cerium ammonium nitrate corresponding to cerium oxide in 800ml of deionized water, add 62.2g of EDTA, and stir for 1h; in the second beaker, add 280g of zirconium Dissolve in deionized water and stir for 1 hour; in the third beaker, dissolve 22.4g of lanthanum nitrate corresponding to lanthanum oxide and 33.6g of yttrium nitrate corresponding to yttrium oxide with 700ml of deionized water, and stir the solution until clear.

[0084] Mix the solutions in the three beakers, stir until clear, and adjust the pH to 1.5 with ammonia water in a water bath at 40°C. At this time, t...

Embodiment 3

[0088] This embodiment provides a composite oxide based on cerium oxide, zirconium oxide, lanthanum oxide, and neodymium oxide and a preparation method thereof.

[0089] Among them, the proportions of cerium oxide, zirconium oxide, lanthanum oxide and neodymium oxide are: 40%, 50%, 4%, 6% by weight.

[0090] The preparation method is:

[0091] In the first beaker, dissolve 224g of cerium ammonium nitrate corresponding to cerium oxide in 800ml of deionized water, add 62.2g of EDTA, and stir for 1h; in the second beaker, add 280g of zirconium Dissolve in deionized water and stir for 1 hour; in the third beaker, dissolve 22.4g of lanthanum nitrate corresponding to lanthanum oxide and 33.6g of yttrium nitrate corresponding to neodymium oxide with 700ml of deionized water, and stir the solution until clear.

[0092] Mix the solutions in the three beakers, stir until clear, and adjust the pH to 1.5 with ammonia water in a water bath at 40°C. At this time, the solution is clear and ...

PUM

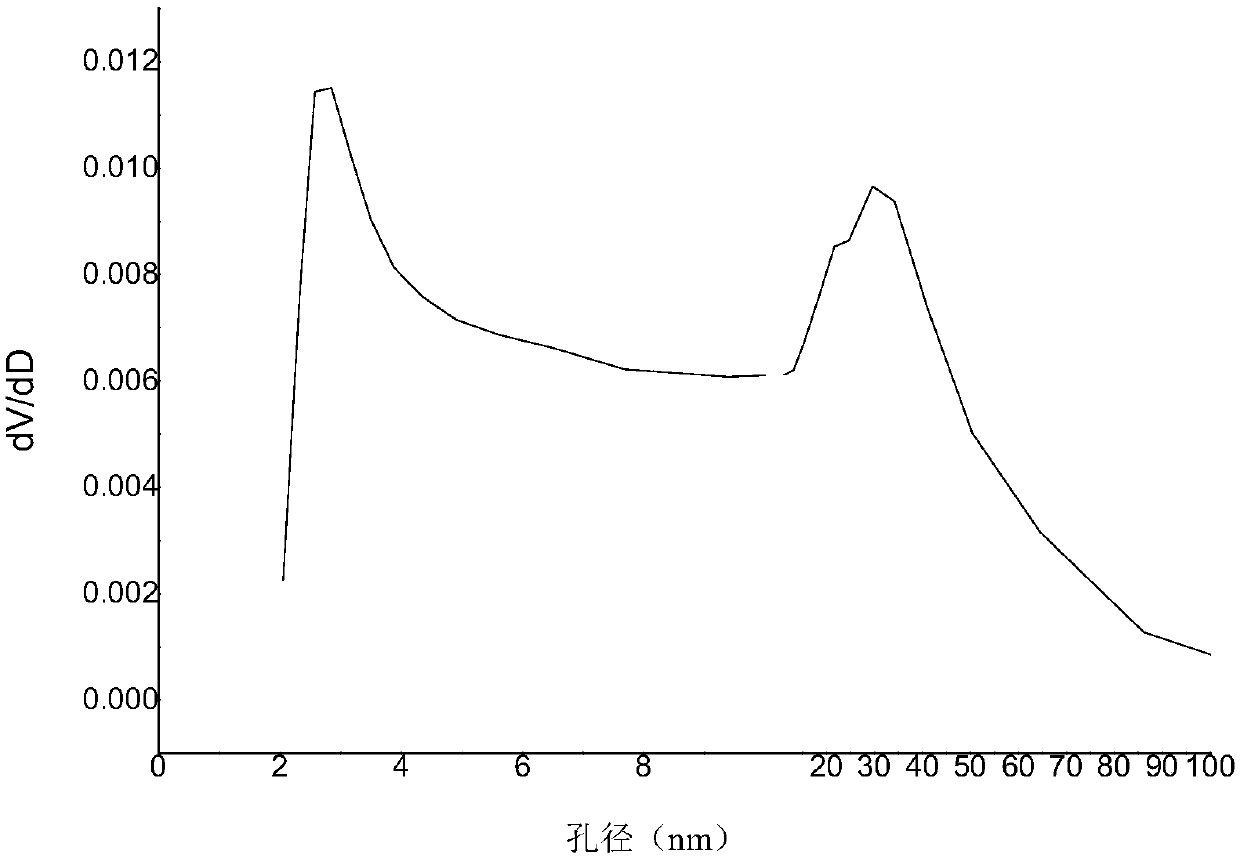

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com