Method for preparing large-particle cerium oxide

A cerium oxide, large particle technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problem of high production cost, achieve uniform particle distribution, good dispersibility, and easy control of the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

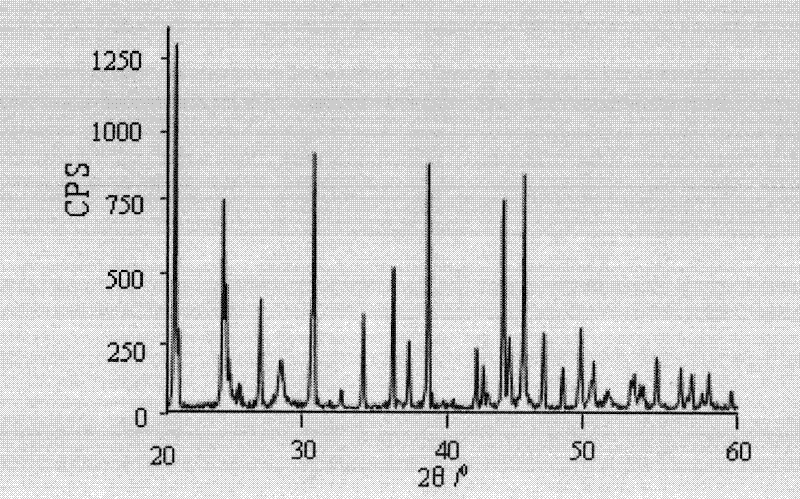

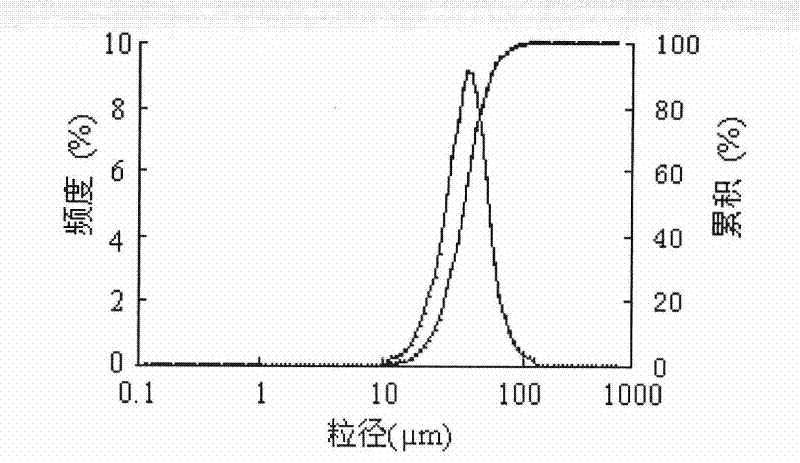

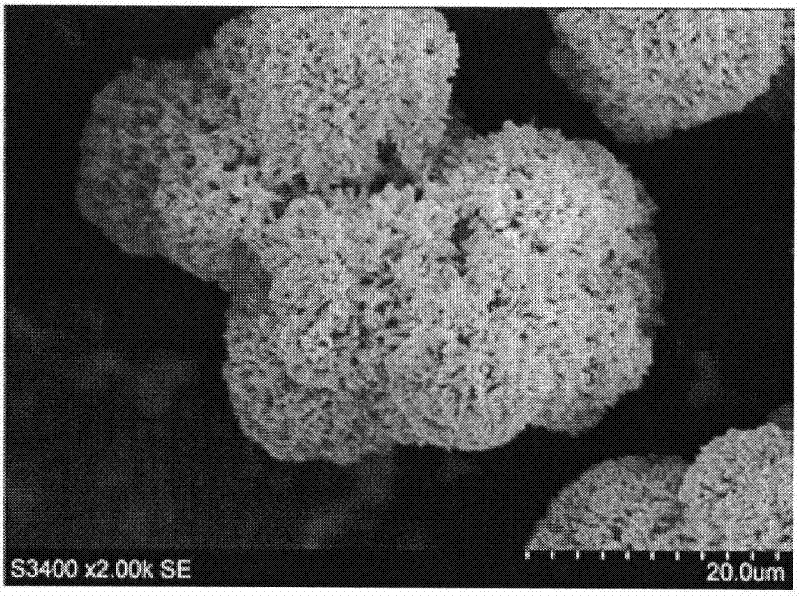

Embodiment 1

[0012] Add 1000L of cerium chloride solution with a concentration of 0.23mol / L into the FK3000 enamel reaction tank, heat the cerium chloride solution to 93°C, add 300L of ammonium bicarbonate solution with a concentration of 2.5mol / L, and the precipitation reaction is completed in 3 hours. After melting for 1 hour, washing and filtering, the cerium oxycarbonate precipitate was obtained, and the cerium oxycarbonate was kept in a firing kiln at 600° C. for 4 hours to obtain a cerium oxide product with a central particle size of 41.73 μm.

Embodiment 2

[0014] Add 1000L of cerium chloride solution with a concentration of 0.35mol / L into the FK3000 enamel reaction tank, heat the cerium chloride solution to 93°C, add 450L of ammonium bicarbonate solution with a concentration of 2.5mol / L, and complete the precipitation reaction for 3 hours. After melting for 1 hour, washing and filtering, the cerium oxycarbonate precipitate was obtained, and the cerium oxycarbonate was kept in a firing kiln at 500° C. for 4 hours to obtain a cerium oxide product with a central particle size of 38.46 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com