Method for preparing size-controlled graphene oxide by clean oxidation technology

A technology of graphene and graphene dispersion liquid, which is applied in the field of graphene oxide, can solve the problems that hinder the mass production of graphene oxide, waste of water resources and energy, and non-recyclable utilization, so as to change the difficulty of separation and purification and make the process safe and controllable , changing the costly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

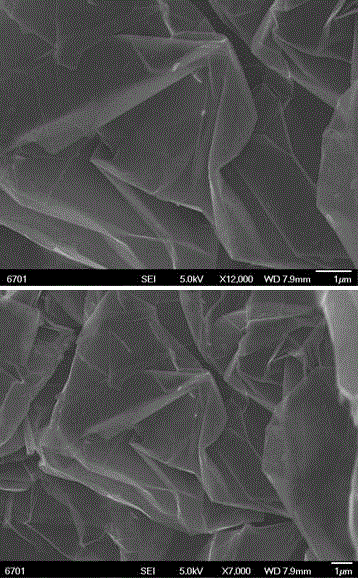

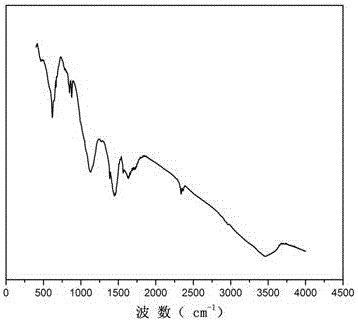

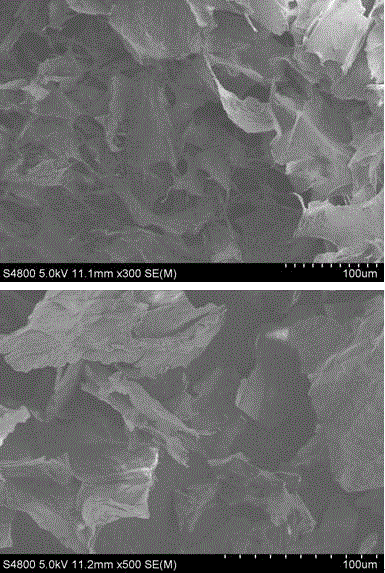

[0026] Using 98wt% concentrated sulfuric acid and potassium permanganate as the oxidation intercalation method to prepare expandable graphite, in this example, 10 g of natural flake graphite with a size of 23 μm was added to 50 mL H 2 SO 4 , 2g KMnO 4 The mixture was stirred for 30 min and then allowed to stand at room temperature for 1 h to prepare expandable graphite. After cleaning the expandable graphite, take out 0.3g, add 0.5mL of 28% ammonia water and 10mL of 30% hydrogen peroxide, then add water to dilute to 30mL, and react in water at 180°C for 6h to obtain the graphite oxide product, then wash the graphite oxide product with deionized water until the water Phase pH = 7, then add 300mL deionized water and 800W ultrasonic dispersion to obtain graphene oxide aqueous dispersion; freeze-dry to prepare graphene oxide powder.

Embodiment 2

[0028] Using 98wt% concentrated sulfuric acid and potassium permanganate as an oxidation intercalation method to prepare expandable graphite, in this example, 10 g of natural flake graphite with a size of 80 μm was first added to 50 mL H 2 SO 4 , 2g KMnO 4 The mixture was stirred for 30 min and then allowed to stand at room temperature for 1 h to prepare expandable graphite. After cleaning the expandable graphite, take out 1g, add 1mL of 28% ammonia water and 5mL of 30% hydrogen peroxide, then add water to dilute to 30mL, and react in water at 100°C for 8h to obtain the graphite oxide product, then wash the graphite oxide product with deionized water until the pH of the water phase =7, then add 800W ultrasonic dispersion in 300mL DMF to obtain graphene oxide aqueous dispersion; spray drying to prepare graphene oxide powder.

Embodiment 3

[0030] Using 98wt% concentrated sulfuric acid and potassium permanganate as an oxidation intercalation method to prepare expandable graphite, in this example, 10 g of natural flake graphite with a size of 75 μm was added to 50 mL H 2 SO 4 , 2g KMnO 4The mixture was stirred for 30 min and then allowed to stand at room temperature for 1 h to prepare expandable graphite. After cleaning the expandable graphite, take out 1g, add 1mL of 28% ammonia water and 8mL of 30% hydrogen peroxide, and then add water to dilute to 60mL. At this time, because the pre-expanded graphite has not been treated, the liquid environment is acidic, and the hydrothermal reaction at 160°C for 10h produces graphite oxide. Afterwards, the graphite oxide product was washed with deionized water until the pH of the water phase was 7, and then 800W ultrasonic dispersion was added to a mixture of 300mL ethanol and water to obtain a graphene oxide water dispersion; spray drying was used to prepare a graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com