Preparation method of DHA lipid nano-particles

A technology of lipid nanoparticles and lipid materials, which is applied in the directions of liposome delivery, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc., can solve the problem of low efficiency and insufficient DHA synthesis to meet the needs of the Development requirements and other issues, to achieve the effect of simple and convenient preparation process, improved DHA stability, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

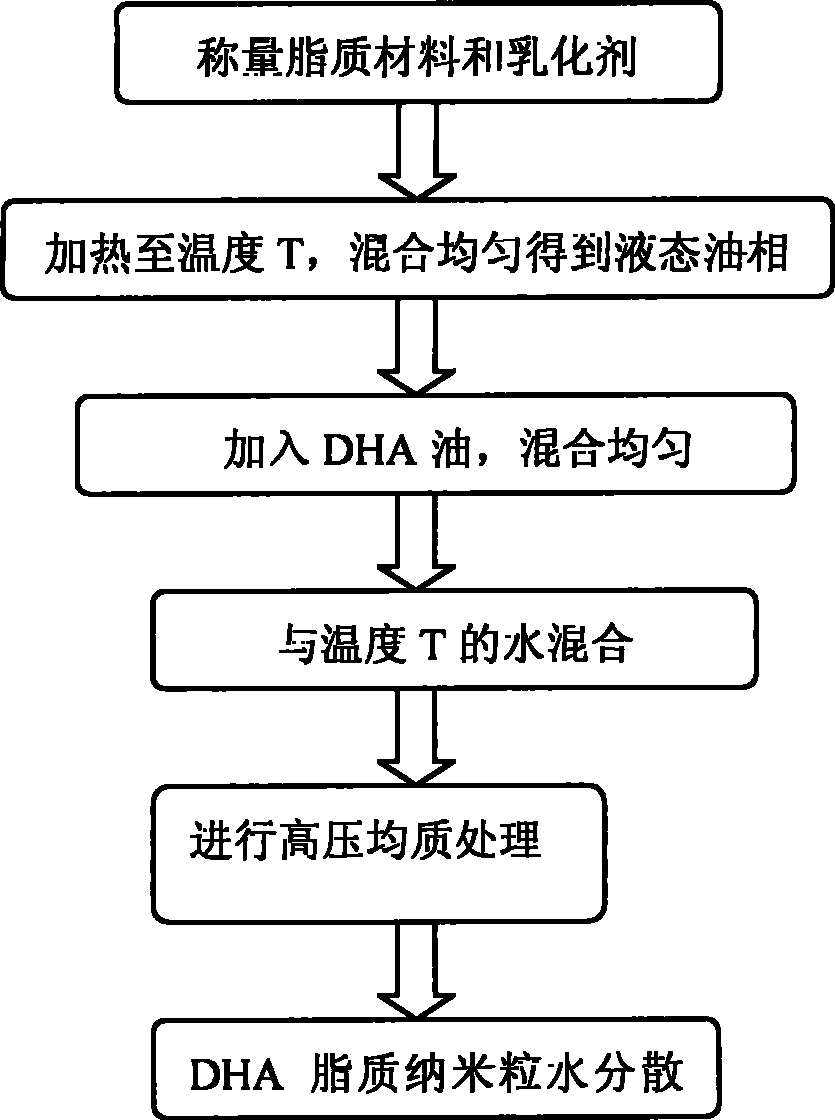

[0022] Embodiment: a kind of preparation method of DHA lipid nanoparticle, comprises the following steps:

[0023] Step 1: Weigh the emulsifier and lipid material separately, the mass ratio of the two is 4:1~1:1, mix the emulsifier and lipid material and heat to the set temperature t, t=70°C, after melting Obtain a liquid oil phase;

[0024] Step 2: Weigh DHA, the mass ratio of DHA to lipid material is 3:1-1:2, add DHA into the liquid oil phase, and stir to obtain a homogeneous system;

[0025] Step 3: Add water at the same temperature as the set temperature t to the above system. The quality of the water is 7 to 30 times that of DHA. After mixing and stirring evenly, enter the preheating process to the set temperature t and set the pressure to 80MPa The high-pressure homogenizer circulates and homogenizes for 5 to 9 times, and water-soluble surfactants can be dissolved in the water;

[0026] Step 4: Cool the obtained high-temperature microemulsion to room temperature to obt...

Embodiment 1

[0031] 1. Weigh 6.48 grams of decaglycerol monolaurate, 4.32 grams of hexapolyglycerol monostearate, 1.2 grams of sucrose ester, and 3 grams of glyceryl monostearate, and put them into a beaker for heating in a 70°C water bath;

[0032] 2. After the substance in the beaker is completely melted, add 5 grams of DHA, heat and stir evenly;

[0033] 3. Add 80 grams of distilled water at 70°C to the above system and stir evenly. At the same time, turn on the high-pressure homogenizer and preheat it with distilled water at 70°C;

[0034] 4. Put the homogeneously stirred high-temperature emulsion system into the high-pressure homogenizer, adjust the homogenization pressure to 80MPa, and circulate the homogenization for 5 times under this pressure;

[0035] 5. Reduce to room temperature to obtain DHA lipid nanoparticle dispersion.

Embodiment 2

[0037] 1. Weigh 2.88 grams of decaglycerol monolaurate, 1.97 grams of hexapolyglycerol monostearate, 1.2 grams of sucrose ester, 1.5 grams of glyceryl monostearate, 1.5 grams of Camellia oleifera seed oil, and put them in a beaker at 70°C Water bath;

[0038] 2. After the substance in the beaker is completely melted, add 5 grams of DHA, heat and stir evenly;

[0039] 3. Add 86 grams of distilled water at 70°C to the above system and stir evenly. At the same time, turn on the high-pressure homogenizer and preheat it with distilled water at 70°C;

[0040] 4. Pour the uniformly stirred high-temperature emulsion system into a high-pressure homogenizer, adjust the homogenization pressure to 80MPa, and circulate the homogenization for 5 times under this pressure;

[0041] 5. Reduce to room temperature to obtain DHA lipid nanoparticle dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com