Multiple emulsion of arbutin and preparation method thereof

A technology of multiple emulsions and arbutin, which is applied in the directions of pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc., can solve the problems of arbutin's poor stability and low bioavailability, and achieve improved drug loading and preparation methods. Simple, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 arbutin multiple emulsion

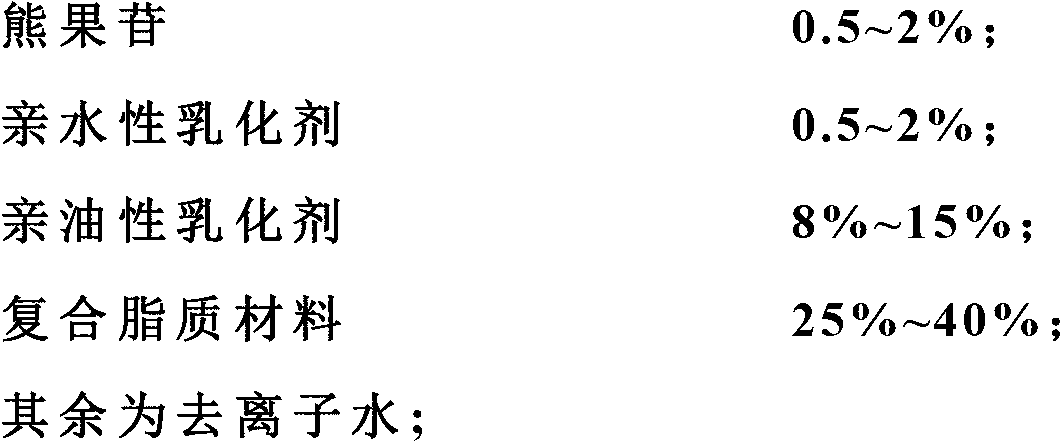

[0041] Composition formula

[0042]

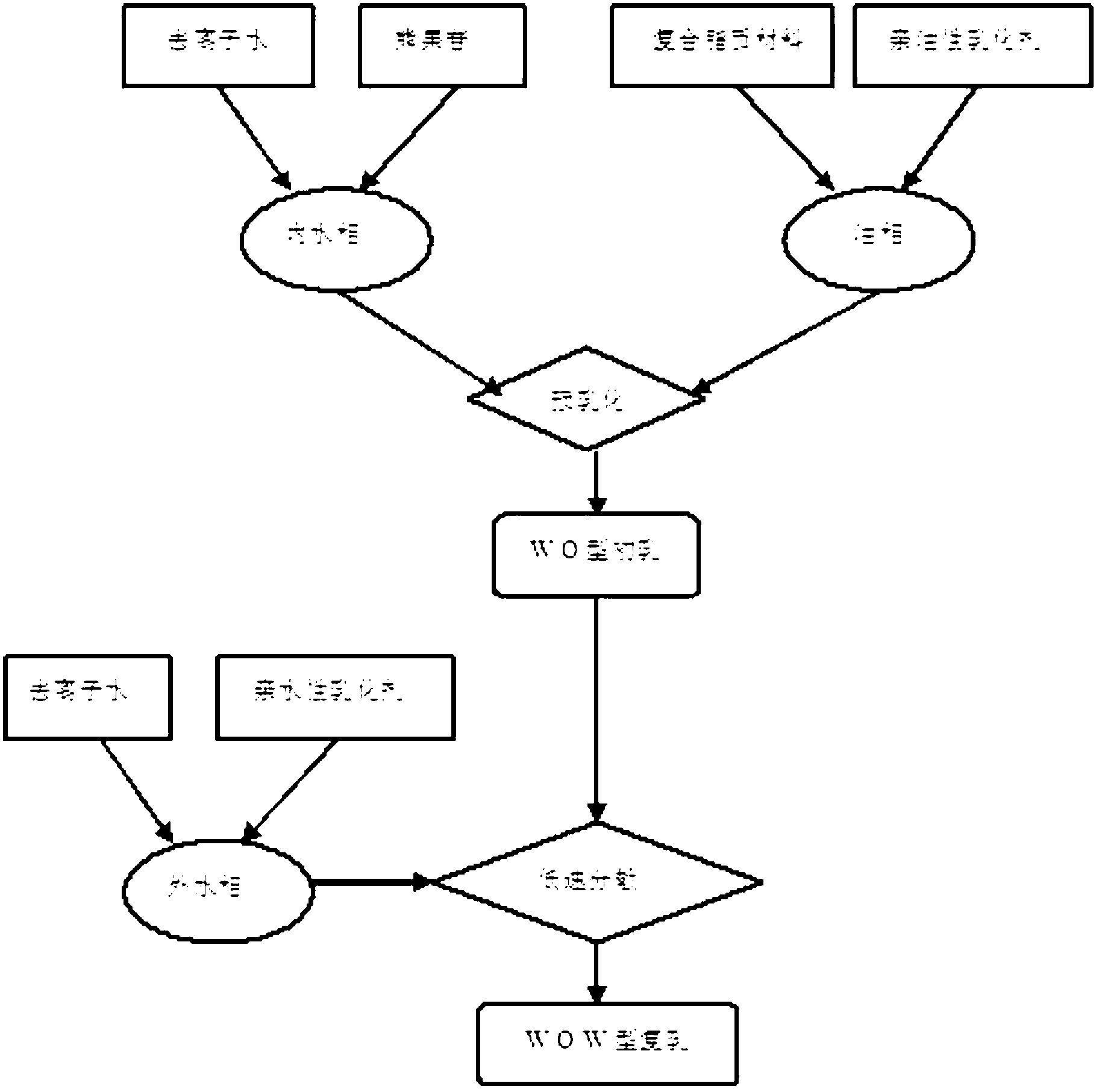

[0043] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0044] 1. Weigh 4.0 grams of glyceryl monostearate, 10.0 grams of soybean lecithin, and 26.0 grams of Camellia oleifera seed oil into a beaker, and heat in a water bath at 65°C.

[0045] 2. Weigh 0.5 grams of arbutin, put 39.5 grams of deionized water into a beaker, and heat it in a water bath at 50°C as the inner water phase;

[0046] 3. Weigh 0.8 g of sucrose ester, put 39.2 g of deionized water into a beaker, and heat in a water bath at 65° C. as the external water phase.

[0047] 4. Add the inner water phase to the oil phase and stir evenly. At the same time, turn on the high-pressure homogenizer and preheat it with deionized water at 65°C;

[0048] 5. Inject the uniformly stirred high-temperature emulsion system into a high-pressure homogenizer, adjust the homogenization pr...

Embodiment 2

[0050] The preparation of embodiment 2 arbutin multiple emulsions

[0051] Composition formula

[0052]

[0053] Preparation steps:

[0054] 1. Weigh 4.0 grams of glyceryl monostearate, 10.0 grams of soybean lecithin, and 26.0 grams of aloe vera oil into a beaker, and heat in a water bath at 55°C;

[0055] 2. Weigh 0.5 grams of arbutin, put 39.5 grams of deionized water into a beaker, and heat it in a water bath at 50°C as the inner water phase;

[0056] 3. Weigh 0.8 g of sucrose ester, put 39.2 g of deionized water into a beaker, and heat in a water bath at 55°C as the external water phase;

[0057] 4. Add the inner water phase to the oil phase, stir evenly, and shear. At the same time, turn on the high-pressure homogenizer and preheat it with 55°C deionized water;

[0058] 5. Inject the uniformly stirred high-temperature emulsion system into the high-pressure homogenizer, adjust the homogenization pressure to 50MPa, and the flow rate to 42dm 3 / h, homogenize for 1min ...

Embodiment 3

[0060] The preparation of embodiment 3 arbutin multiple emulsions

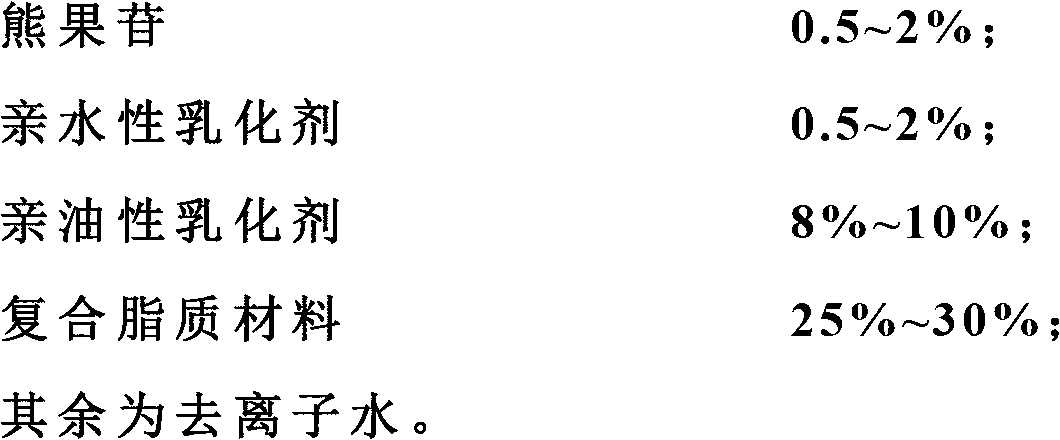

[0061] Composition formula

[0062]

[0063]

[0064] Preparation steps:

[0065] 1. Weigh 4.0 grams of glyceryl monostearate, 10.0 grams of soybean lecithin, and 26.0 grams of soybean oil into a beaker, and heat in a water bath at 70°C;

[0066] 2. Weigh 0.5 grams of arbutin, put 39.5 grams of deionized water into a beaker, and heat it in a water bath at 50°C as the inner water phase;

[0067] 3. Weigh 0.8 g of sucrose ester, put 39.2 g of deionized water into a beaker, and heat in a water bath at 70°C as the external water phase;

[0068] 4. Add the inner water phase to the oil phase, stir evenly, and shear. At the same time, turn on the high-pressure homogenizer and preheat it with 70°C deionized water;

[0069] 5. Inject the uniformly stirred high-temperature emulsion system into the high-pressure homogenizer, adjust the homogenization pressure to 50MPa, and the flow rate to 42dm 3 / h, homogenize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com