Water-glycol fire-resistant hydraulic fluid

A technology of ethylene glycol and hydraulic fluid, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problem that the test conditions are not harsh enough, and achieve good defoaming performance, excellent anti-wear performance, and enhanced high-pressure anti-wear performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

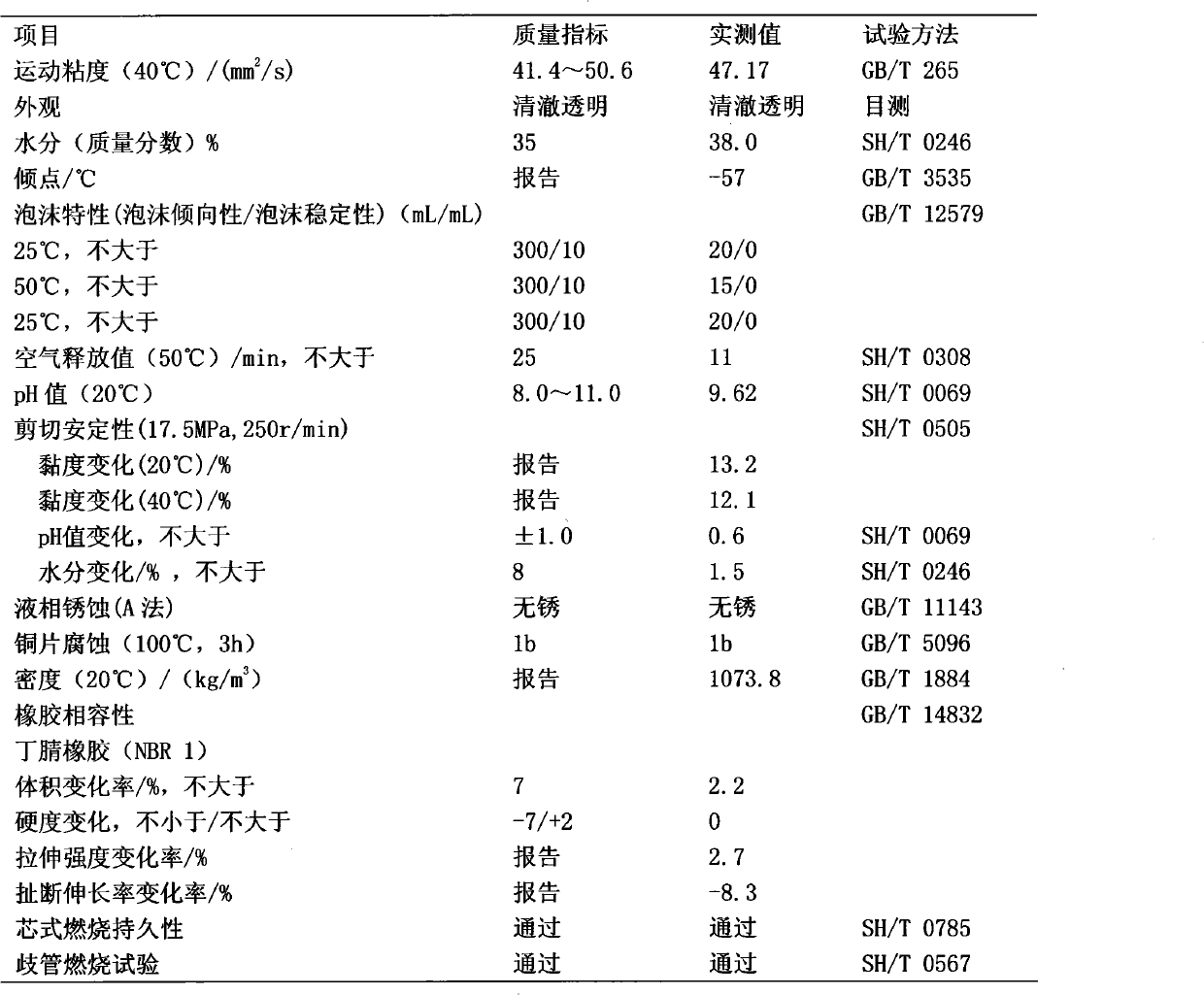

[0017] The following components and their contents (parts by weight) are formulated into water-ethylene glycol fire-resistant hydraulic fluid according to conventional techniques.

[0018] Deionized water 39.78, ethylene glycol balance, ethylene oxide and propylene oxide copolymer (EmkaroxHV45) 14, 2-mercaptobenzothiazole 0.1, capric acid 2.5, caprylic acid 0.5, monoisopropanolamine 1.0, N, N-dimethylethanolamine 2.0, 1,2,4-triazole 0.1, edetate disodium 0.01, benzoic acid 0.005, defoamer (DOWFS1224) 0.005. The kinematic viscosity of ethylene oxide and propylene oxide copolymer at 100°C is 2000mm 2 / s.

Embodiment 2

[0020] The following components and their contents (parts by weight) are formulated into water-ethylene glycol fire-resistant hydraulic fluid according to conventional techniques.

[0021] Deionized water 40, ethylene glycol balance, ethylene oxide and propylene oxide copolymer (EmkaroxHV45) 14, 2-mercaptobenzothiazole carboxylic acid derivative 0.1, capric acid 1.5, monoisopropanolamine 1.0, N , N-dimethylethanolamine 2.0, 3-amino-1,2,4-triazole 0.1, disodium edetate 0.02, benzoic acid 0.018, defoamer (DOWFS1224) 0.002. Ethylene oxide and propylene oxide copolymer has a kinematic viscosity of 7000mm at 100°C 2 / s.

Embodiment 3

[0023] The following components and their contents (parts by weight) are formulated into water-ethylene glycol fire-resistant hydraulic fluid according to conventional techniques.

[0024] Deionized water 37, ethylene glycol balance, deionized water 37, water-soluble polyether (EmkaroxHV45) 13.76, 2-mercaptobenzothiazole 0.1, capric acid 2.5, caprylic acid 0.5, monoisopropanolamine 1.0, N, N -Dimethylethanolamine 2.0, methylbenzotriazole 0.1, edetate disodium 0.017, benzoic acid 0.02, defoamer (DOWFS1224) 0.003.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com