Calcipotriol betamethasone ointment and preparation method thereof

A technology of calcipotriol and betamethasone, applied in the field of medicine, can solve the problems of increased impurities, phase separation, uneven content and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

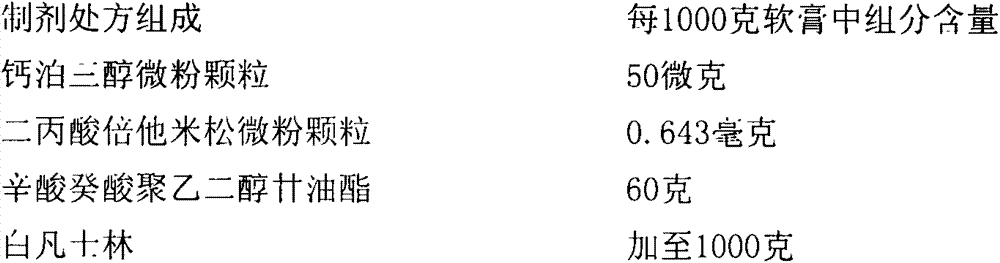

[0051] Recipe for Ointment 1

[0052]

[0053] making process:

[0054] (a) Micronizing calcipotriol and betamethasone until 90% of the particle size is less than 15 microns, and the particle size range is between 5-110 microns.

[0055] (b) Add (a) to caprylic capric acid macrogol glyceride under high-speed cutting and homogenization, and the temperature is controlled at 40-60°C

[0056] (c) Melt white vaseline at 80°C and keep warm at 70°C

[0057] (d) While stirring continuously, mix the material obtained in step (b) and (c) homogeneously, and control the temperature at 55-70°C

[0058] (e) Cool down to 25-35° C., and pack to obtain calcipotriol-betamethasone ointment.

[0059] The ointment was placed at 40°C and 50°C for 10 days respectively, and the properties of the ointment and the related substances and contents of betamethasone dipropionate were investigated. See Table 1 and Table 2 for the results.

Embodiment 2

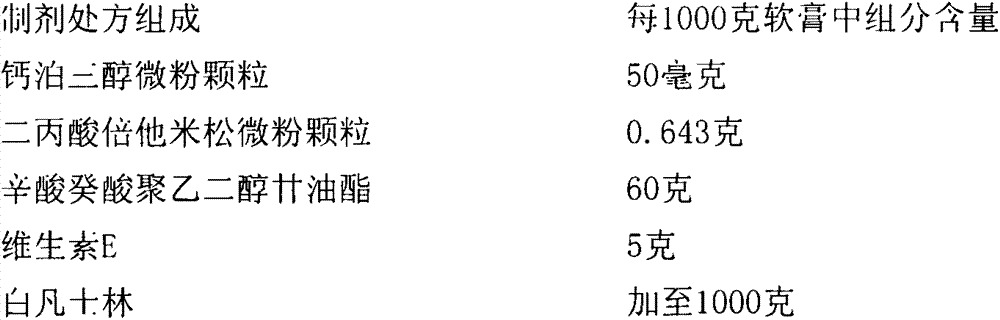

[0061] Recipe for ointment 2

[0062]

[0063] making process:

[0064] (a) Micronizing calcipotriol and betamethasone until 90% of the particle size is less than 15 microns, and the particle size range is between 5-50 microns.

[0065] (b) Add (a) to caprylic capric acid macrogol glyceride under high-speed cutting and homogenization, and the temperature is controlled at 40-60°C

[0066] (c) Melt white vaseline at 80°C and keep warm at 70°C

[0067] (d) Add vitamin E to (c) and stir well.

[0068] (e) While stirring continuously, mix the material obtained in step (b) and (d) homogeneously, and control the temperature at 55-70°C

[0069] (f) cooling down to 25-35° C., and dispensing to obtain calcipotriol-betamethasone ointment.

[0070] The ointment was placed at 40°C and 50°C for 10 days respectively, and the properties of the ointment and the related substances and contents of betamethasone dipropionate were investigated. See Table 1 and Table 2 for the results.

Embodiment 3

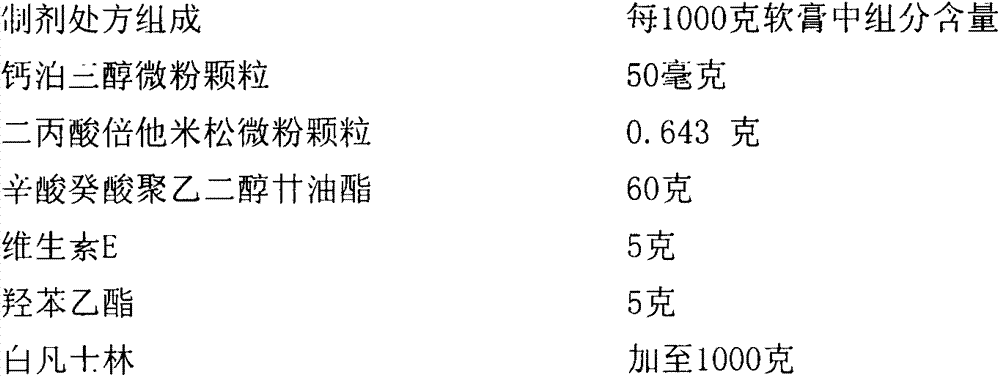

[0072] Recipe for ointment 3

[0073]

[0074] making process:

[0075] (a) Micronizing calcipotriol and betamethasone until 90% of the particle size is less than 15 microns, and the particle size range is 5-15 microns.

[0076] (b) Add (a) to caprylic capric acid macrogol glyceride under high-speed cutting and homogenization, and the temperature is controlled at 40-60°C

[0077] (c) Melt white vaseline at 80°C and keep warm at 70°C

[0078] (d) Add vitamin E and ethylparaben to (c) and stir well.

[0079] (e) While stirring continuously, mix the material obtained in step (b) and (d) homogeneously, and control the temperature at 55-70°C

[0080] (f) cooling down to 25-35° C., and dispensing to obtain calcipotriol-betamethasone ointment.

[0081] The ointment was placed at 40°C and 50°C for 10 days respectively, and the properties of the ointment and the related substances and contents of betamethasone dipropionate were investigated. See Table 1 and Table 2 for the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com