Betamethasone dipropionate nano freeze-dried powder injection and preparation method thereof

A technology of betamethasone dipropionate and nano-freeze-dried powder, which is applied in freeze-dried transportation, powder transportation, pharmaceutical formulations, etc., and can solve problems such as unguaranteed uniformity, reduced proportion of active pharmaceutical ingredients, and poor micronization effect. To achieve the effect of improving bioavailability, reducing impact and fully bearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials are selected as follows

[0028] betamethasone dipropionate 10mg Poloxamer 188 60mg Sodium carboxymethyl cellulose 35mg Povidone K17 50mg Good solvent ethanol 300mg Water for Injection 1g

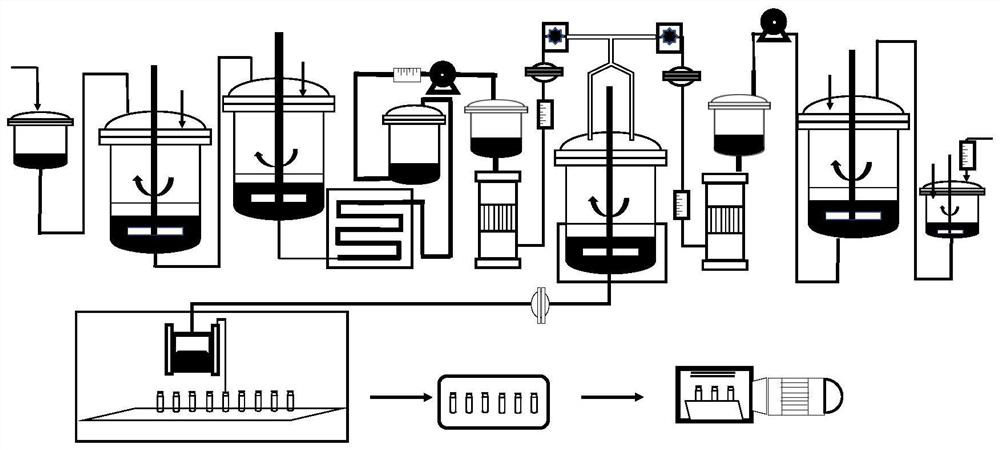

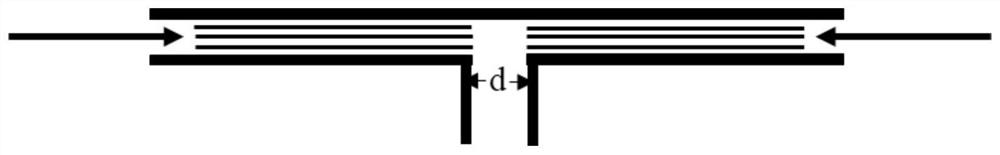

[0029] see figure 1 The process flow is that the ethanol is first passed through the ethanol through the weighing tank and then added to the mixing tank, stirred and mixed with betamethasone dipropionate and poloxamer 188, and then completely dissolved through the slurry tank and high-efficiency dissolver, and finally passed through the solution tank It is pumped out to the middle tank, and after being filtered by an ultrafilter and a 0.22μm membrane, it enters the microchannel under the action of a peristaltic pump; then the water for injection, sodium carboxymethyl cellulose and povidone K17 are stirred and mixed in the mixing tank , added to the slurry tank and continued to stir until completely dissolved, then p...

Embodiment 2

[0032] The raw materials are selected as follows

[0033]

[0034]

[0035] see figure 1 The technological process of this method is that the ethanol is first passed through the ethanol through the weighing tank and then added to the mixing tank, stirred and mixed with betamethasone dipropionate and polysorbate 80, and then completely dissolved through the slurry tank and high-efficiency dissolving machine, and finally passed through the solution tank It is pumped out to the middle tank, and after being filtered by an ultrafilter and a 0.22μm membrane, it enters the microchannel under the action of a peristaltic pump; then the water for injection, sodium alginate and povidone K17 are stirred and mixed in the mixing tank, and added to the Continue to stir in the slurry tank until it is completely dissolved, pump it into the middle tank through a rotary pump, and then enter the microchannel under the action of a peristaltic pump after being treated with an ultrafilter and ...

Embodiment 3

[0037] The raw materials are selected as follows

[0038] betamethasone dipropionate 10mg Polysorbate 80 70mg sodium alginate 40mg carboxymethyl cellulose 60mg Good solvent tert-butanol 300mg Water for Injection 0.6g

[0039] see figure 1 The technological process is that tert-butanol is put into the mixing tank after ethanol is passed through the weighing tank, stirred and mixed with betamethasone dipropionate and polysorbate 80, and then completely dissolved through the slurry tank and high-efficiency dissolving machine, and then passed through The solution pool is pumped out to the middle pool, and after being filtered by an ultrafilter and a 0.22 μm membrane, it enters the microchannel under the action of a peristaltic pump; then the water for injection, sodium alginate and carboxymethyl cellulose are stirred and mixed in the mixing pool , added to the slurry tank and continued to stir until completely dissolved, then pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com