Phase change composite material and preparation method thereof

A phase-change composite material and phase-change material technology, applied in the field of phase-change composite materials and their preparation, can solve the lack of effective verification and in-depth research on the application adaptability and application methods of phase-change materials or phase-change composite materials, and no proposal Building energy-saving solutions, poor mechanical properties and durability, etc., to achieve good circulation melting, no supercooling and precipitation, and rapid film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 55 parts by weight of a phase change material made by blending decanoic acid, dodecanoic acid and myristic acid with a weight ratio of 25%, 33% and 42% respectively, and 100 parts by weight of expanded perlite particles were placed in an environment of 18°C. Put it into a closed container, evacuate to 75kPa, keep the vacuum pressure constant, heat the closed container to 65°C, keep it warm for 2h, gradually cool down to 18°C, and take out the expanded perlite particles that have adsorbed the phase change material. The expanded perlite particles that have adsorbed the phase change material are placed in a rotating container that can continuously turn the material, and 73.5 parts by weight of the polymer emulsion are sprayed on its surface in a mist, and the obtained particle surface film thickness is 0.03mm. Continue to turn the material until the surface is dry. The selected polymer emulsion is 3099 styrene-acrylic emulsion of Federal Chemical Industry.

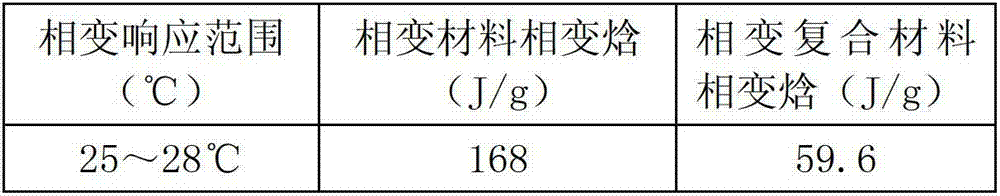

[0029] The pe...

Embodiment 2

[0035] 75 parts by weight of the phase change material made by blending 37.5%, 33% and 29.5% by weight of decanoic acid, dodecanoic acid and myristic acid, and 100 parts by weight of expanded perlite were placed in an environment of 20°C. In the airtight container, evacuate to 80kPa, keep the vacuum pressure constant, heat the airtight container to 70°C, keep it warm for 4 hours, gradually cool down to 18°C, and take out the expanded perlite particles that have absorbed the phase change material. The expanded perlite particles that have absorbed the phase change material are placed in a rotating container that can continuously turn the material, and 200 parts by weight of the polymer emulsion are sprayed on the surface in a mist form, and the surface film thickness of the obtained particles is 0.05mm. Continue to turn the material until the surface is dry. The selected polymer emulsion is Lianlian Chemical A-119 acrylic emulsion.

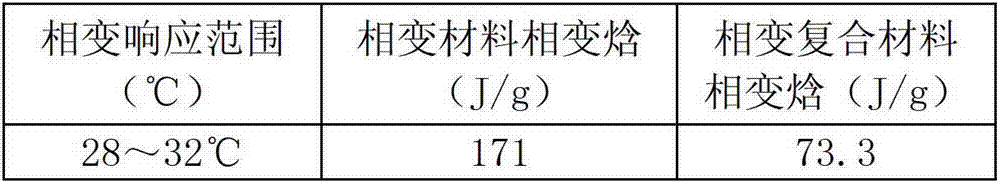

[0036] The performance of the phase-change c...

Embodiment 3

[0042] 58 parts by weight of phase-change materials blended by decanoic acid, dodecanoic acid, myristic acid and palmitic acid by weight respectively at 25%, 34.5%, 25% and 15.5%, and 100 parts by weight of expanded perlite, Put it in an airtight container at 0°C, evacuate to 78kPa, keep the vacuum pressure constant, heat the airtight container to 68°C, keep it warm for 3 hours, gradually cool down to 5°C, and take out the expansion that has absorbed the phase change material Perlite grains. The expanded perlite particles that have absorbed the phase change material are placed in a rotating container that can continuously turn the material, and 50 parts by weight of the polymer emulsion is sprayed on its surface in a mist form, and the surface film thickness of the obtained particles is 0.025mm. Continue to turn the material until the surface is dry. The selected polymer emulsion is Lianlian Chemical A-119 acrylic emulsion.

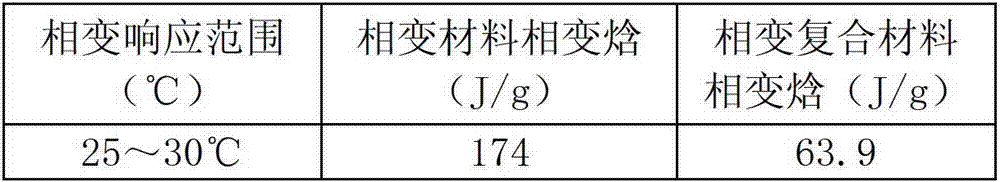

[0043] The performance of the phase-change compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com