Process for preparing organic cobalts mixed salt finished product with cobalt neodecanoate as main raw material

A technology of cobalt neodecanoate and mixed salt, which is applied in the field of organic chemical industry, can solve the problems of unfavorable rubber production, inconvenient transportation, low melting point, etc., and achieve the effects of improving adhesion, balancing pH, and weakening free acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

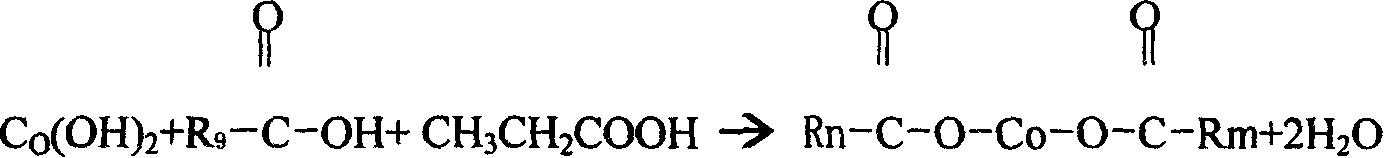

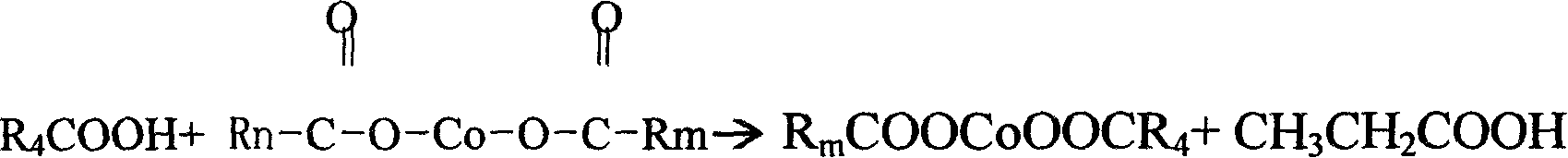

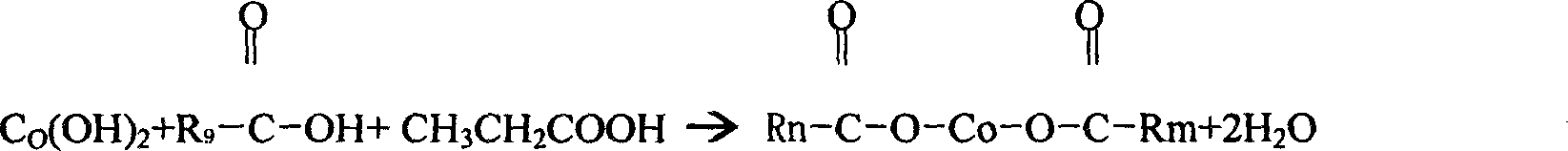

Method used

Image

Examples

Embodiment 1

[0034] In a 500ml three-necked flask with a moisture collector, a back distillation condenser, and a vacuum pump, add 38g of propionic acid, 160g of neodecanoic acid, and 85g of cobalt hydroxide, and control the reaction temperature at 150-170°C for 2 hours. Emit waste water, then add 40 g of pivalic acid and stir, control the heating temperature at 200° C. and keep the reaction for 1 hour, and emit waste water and propionic acid. Then add 2.5g of calcium metaborate, control the temperature at 190-200°C, stir evenly for half an hour and discharge. The cobalt content of the reaction product: 20.40%, the melting point: 88°C, and the appearance is blue-purple solid.

Embodiment 2

[0036] In a 1000ml three-necked flask with a moisture collector, a back distillation condenser, and a vacuum pump, add 78g of propionic acid, 317g of neodecanoic acid, and 167g of cobalt hydroxide, and control the reaction temperature at 170-190°C. The reaction time is 2.5 hours. Release waste water, then add 82g of pivalic acid and stir, control the heating temperature at 190-195°C and keep it warm for 1 hour, release waste water and propylene, then add 7.0g of calcium metaborate, control the temperature at 190-200°C, and stir evenly for half an hour After discharging, the cobalt salt of the reaction product contains 20.45% cobalt, melting point: 92°C, and appears as a blue-purple solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com