Demoulding agent used for precast concrete component and preparation method thereof

A technology for prefabricated components and concrete, applied in the direction of lubricating compositions, etc., can solve the problems of easy spoilage, de-powder on the concrete surface, difficult to repaint, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

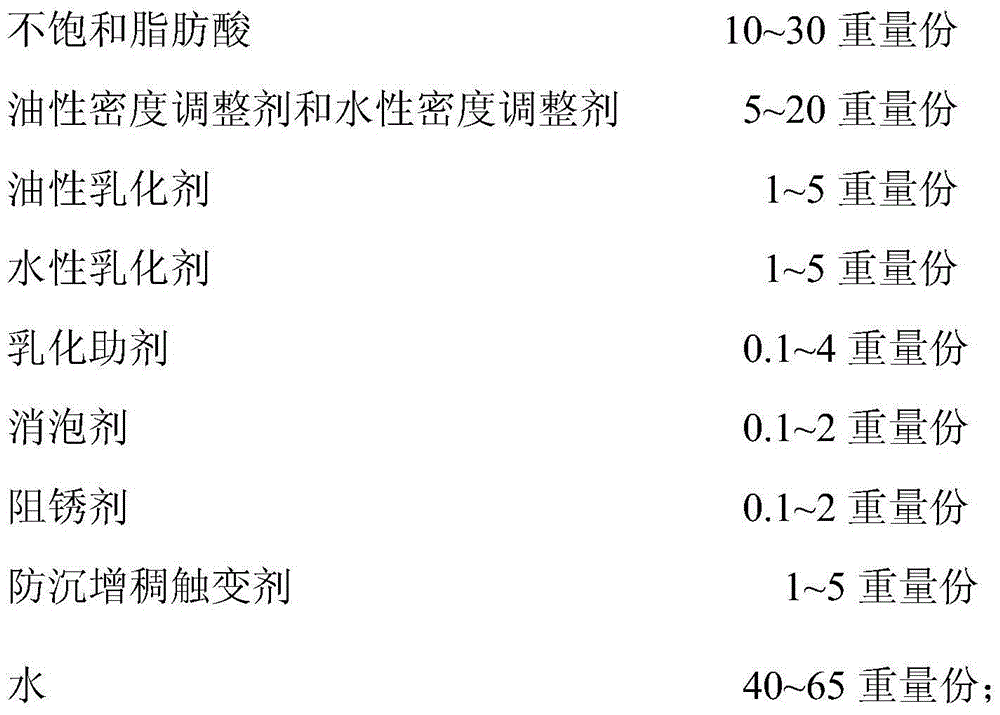

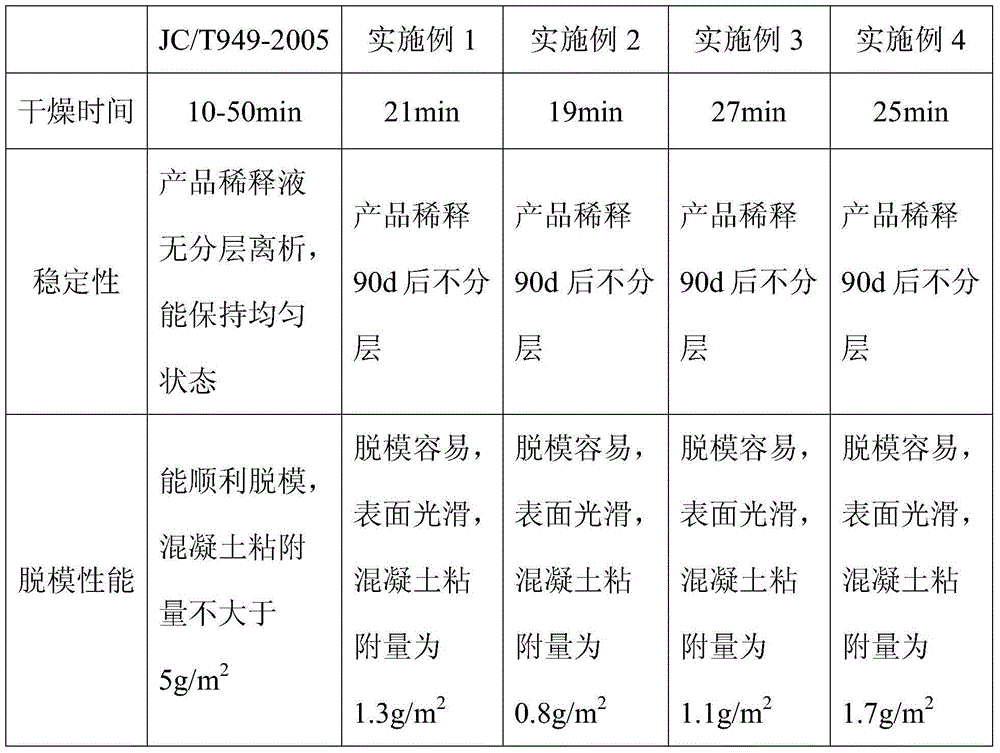

[0031] In parts by weight, take 20 parts of oleic acid, 5 parts of brominated vegetable oil, 2 parts of Span40 and 0.5 part of emulsifying aid, add them to the reaction kettle, stir for 50 minutes; then add 2 parts of OP-10 and 2 parts of sodium lauryl sulfate , stirred for 30 minutes; then slowly added 56 parts of water and 10 parts of ethanol, stirred for 30 minutes; finally added 0.2 parts of GB123, 0.1 part of sodium benzoate and 4 parts of hydrophobically modified hydroxyethyl cellulose, and stirred for 40 minutes to obtain the concrete Release agent for prefabricated elements.

Embodiment 2

[0033] In parts by weight, take 20 parts of ricinoleic acid, 2 parts of brominated vegetable oil, 2 parts of Span602 and 1 part of emulsifying aid, add them to the reaction kettle, and stir for 50 minutes; then add 102 parts of OP, and stir for 30 minutes; then slowly add 64 parts of water , 7 parts of ethanol, and stirred for 30 minutes; finally, 0.1 parts of YN104, 1.3 parts of sodium benzoate and 2 parts of water-based polyurethane thickener were added, and after stirring for 40 minutes, the release agent for concrete prefabricated components was obtained.

Embodiment 3

[0035] In parts by weight, take 18 parts of palmitoleic acid, 4 parts of brominated vegetable oil, 2 parts of Span20 and 1 part of emulsifying aid, add them to the reaction kettle, stir for 50 minutes; then add 3 parts of Tween-60, stir for 30 minutes; then slowly add water 59 and 11 parts of ethanol, stirred for 30 minutes; finally, 1.2 parts of YN104, 0.1 part of sodium monofluorophosphate and 2 parts of water-based polyurethane thickener were added, and after stirring for 40 minutes, the release agent for concrete prefabricated components was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com