Method for producing palmitoleic acid from Eustigmatophyceae microalgae

A technology of euphratica and palmitoleic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high cost, unsuitable for large-scale production, and low purity of palmitoleic acid, and achieve The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

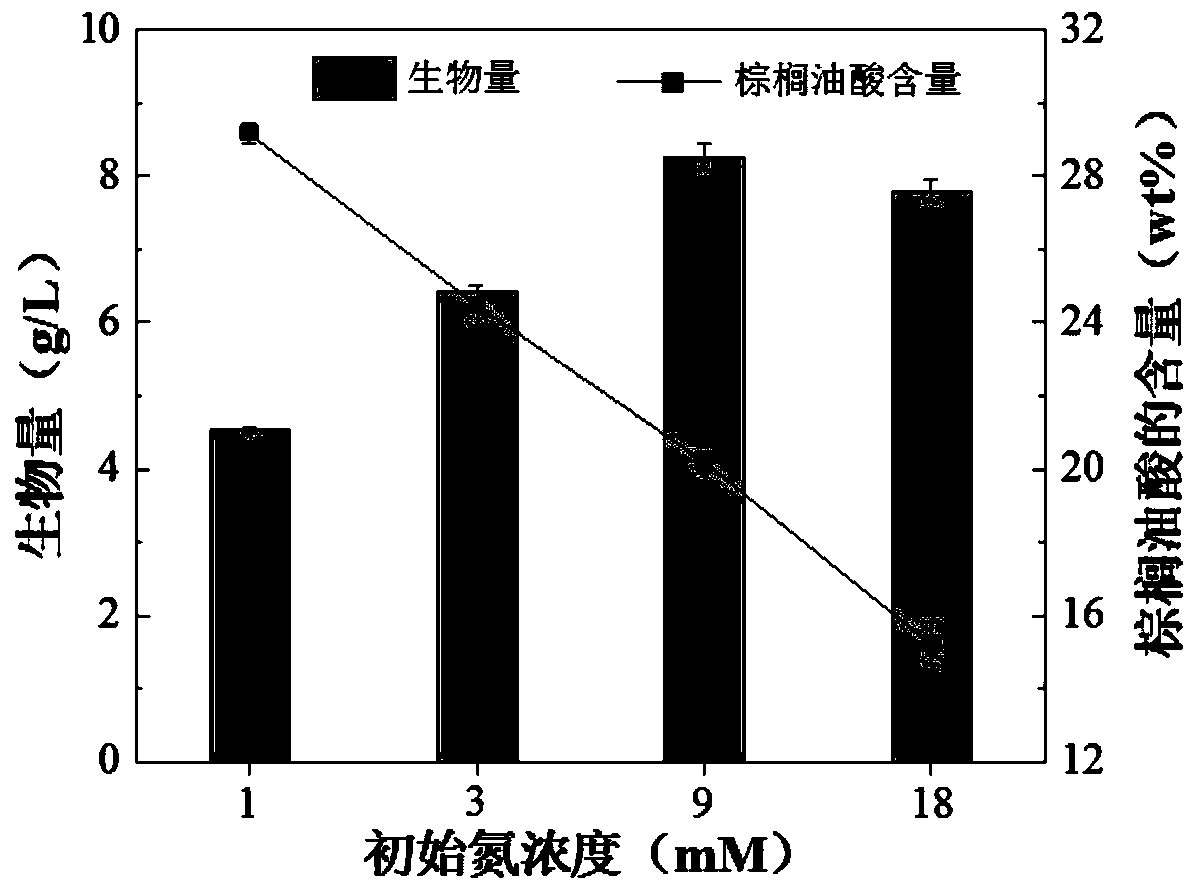

[0039] Example 1 The optimal initial nitrogen concentration of E.cf.polyphem highly accumulating palmitoleic acid

[0040] Experimental material: E.cf.polyphem (E.cf.polyphem) (expanded and cultivated)

[0041] Medium preparation: mBG-11 liquid medium, 1.5g / L NaNO 3 , 0.04g / L K 2 HPO 4 , 0.075g / LMgSO 4 ·7H 2 O, 0.036g / L CaCl 2 2H 2 O, 0.006g / L citric acid, 0.006g / L FeCl 3 ·6H 2 O, 0.001g / LEDTA, 0.02g / L Na 2 CO 3 , 2.860g / L H 3 BO 3 , 1.810g / L MnCl 2 4H 2 O, 0.391g / L Na 2 MoO 4 2H 2 O, 0.079g / L CuSO 4 ·5H 2 O, 0.220g / L ZnSO 4 ·7H 2 O, 1L deionized water, sterilized at 121°C for 20min. where NaNO 3 As a nitrogen source, 4 different initial concentrations were set, namely 18mM (1.5g), 9mM (0.75g), 3mM (0.25g) and 1mM (0.08g).

[0042] experiment method:

[0043] The strains of E.cf.polyphem that had been expanded were divided according to the OD 750 = 0.60 ± 0.02 initial inoculation density into the optical columnar glass bioreactor (diameter × height = 3...

Embodiment 2

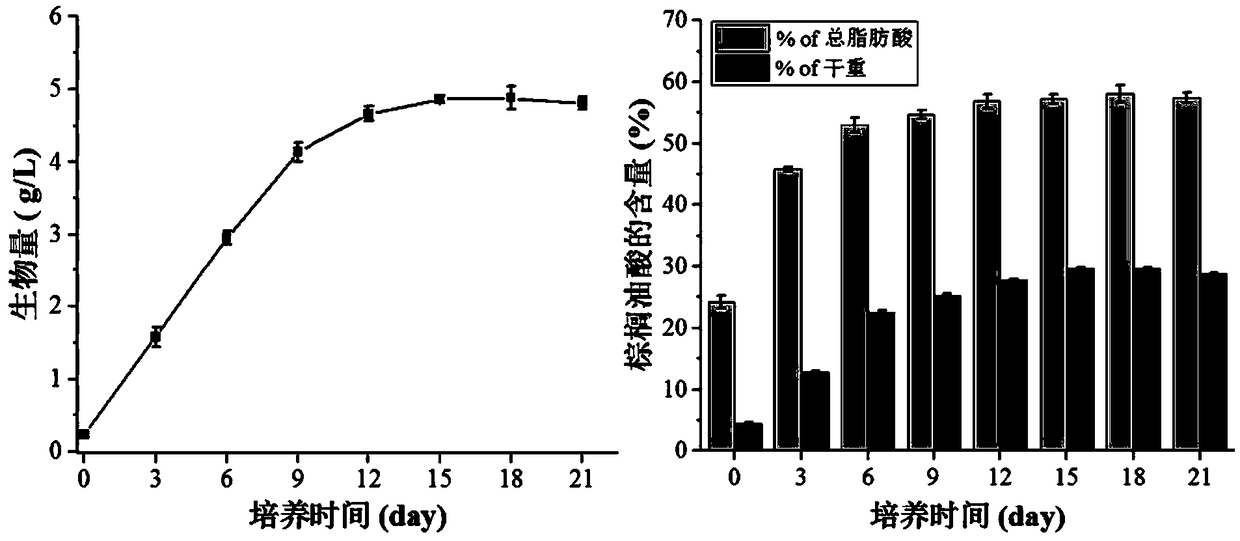

[0047] Phase changes in the growth and palmitoleic acid accumulation of E.cf.polyphem (E.cf.polyphem) under nitrogen stress conditions (1mM) in Example 2

[0048] Experimental material: Euophthalmos bordetii-like (expansion and cultivation have been carried out)

[0049] Medium preparation: mBG-11 liquid medium, 0.08g / L NaNO 3 , 0.04g / L K 2 HPO 4 , 0.075g / LMgSO 4 ·7H 2 O, 0.036g / L CaCl 2 2H 2 O, 0.006g / L citric acid, 0.006g / L FeCl 3 ·6H 2 O, 0.001g / LEDTA, 0.02g / L Na 2 CO 3 , 2.860g / L H 3 BO 3 , 1.810g / L MnCl 2 4H 2 O, 0.391g / L Na 2 MoO 4 2H 2 O, 0.079g / L CuSO 4 ·5H 2 O, 0.220g / L ZnSO 4 ·7H 2 O, 1L deionized water, sterilized at 121°C for 20min.

[0050] experiment method:

[0051] The euopteris strains that have been expanded were divided according to the OD 750=0.60±0.02 initial inoculation density was inserted into mBG-11 liquid medium with an initial nitrogen concentration of 1 mM, and cultured in a bright columnar glass bioreactor with diameter×heigh...

Embodiment 3

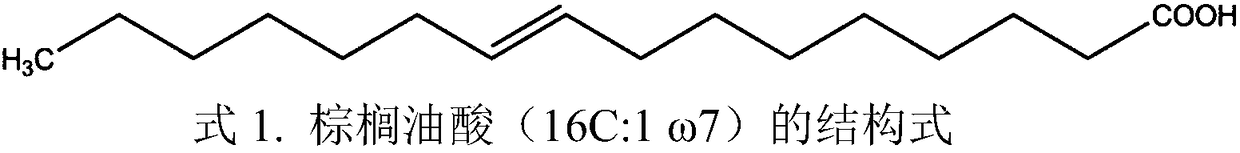

[0053] The preparation of palmitoleic acid in the embodiment 3 classes E.cf.polyphem (E.cf.polyphem)

[0054] Experimental material: Freeze-dried algae powder of E.cf.polyphem under the culture condition of 1mM nitrogen concentration

[0055] experiment method:

[0056] (1) Oil extraction: take freeze-dried algae powder and 95% ethanol and mix according to the ratio of m / v=1:30, put it in an ultrasonic cleaning machine and continue ultrasonic treatment for 2.5 hours. After ultrasonic pretreatment, the flask containing the algae solution was placed in a constant temperature water bath at 50° C., and extracted for 4 hours with continuous stirring (200 rpm) by an electric stirrer. After the extraction, centrifuge at 3500rpm for 5min, collect the supernatant, and continue to repeat the above extraction steps for 3 to 4 times for algae. After combining the supernatants, use a rotary evaporator (50° C.) to recover ethanol to obtain total lipids. Detected by gas chromatography, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com