Grease composition and preparation method thereof

A technology of oil composition and oil, applied in edible oil/fat, dairy products, food science, etc., to achieve the effect of reducing requirements and expanding sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Preparation method of oil composition

[0055] The preparation method of the oil composition of the present invention includes the step of randomly transesterifying the oil, the content of oleic acid in the oil is more than 40% by weight, and the content of palmitic acid is more than 25% by weight.

[0056] In the method of the present invention, the oil is: high oleic acid palm oil, high oleic acid high palmitic sunflower oil or a mixture of the above oils and other animal-derived or vegetable-derived oils. The animal source oil is deep-sea fish oil, such as salmon oil, sardine oil and the like. The vegetable-derived oil is selected from rice oil, sunflower oil, rapeseed oil, palm oil, palm kernel oil, peanut oil, rapeseed oil, soybean oil, cottonseed oil, safflower oil, perilla seed oil, tea seed oil, Olive oil, cocoa bean oil, tallow seed oil, almond oil, almond oil, tung oil, rubber seed oil, corn oil, wheat germ oil, sesame seed oil, castor oil, evening primrose o...

Embodiment

[0166] The high oleic high palmitic sunflower oil used in the examples of the present invention comes from the Spanish market.

[0167] The determination method of fatty acid composition in the product in the embodiment of the present invention is AOCSCelb-89.

[0168] The method for determining the ratio of palmitic acid at the Sn-2 position to the total palmitic acid in the products in the examples of the present invention is AOCSCh3-91.

[0169] The oleic acid in the embodiment of the present invention comes from Kerry Oleochemical Industry (Shanghai), the ethyl oleate is purchased from Aladdin Reagent Company, the palm oil is from Kerry Special Oils (Shanghai) Co., Ltd., LipzoymeRMIM and NS40086 are from Nuo we-chat.

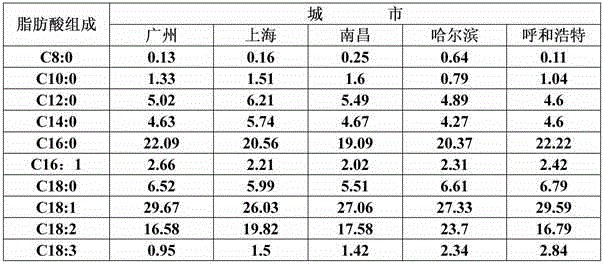

[0170] Table 2 Differences of main fatty acids between high oleic high palmitic sunflower oil and ordinary sunflower oil

[0171] fatty acid High Oleic High Palm Sunflower Oil (wt%) Ordinary sunflower oil (wt%) C16:0 31.7 6.6 C18:0 ...

Embodiment 1

[0175] step 1

[0176] Heat 1.5 kg of the refined high oleic high palmitic acid sunflower oil shown in Table 2 to 105°C, stir in vacuum for 1 hour for dehydration; add 0.5% sodium methoxide, react at 80°C for 45 minutes; add 20% of the weight of the above mixture citric acid aqueous solution (concentration 8%), stirred for 20min to terminate the reaction. The reactant was repeatedly washed with hot water until pH = 7, and the soap was removed. Heat to 105°C, stir in vacuum for 30 minutes to dehydrate and dry; add 2% activated clay by weight of the above-mentioned dehydrated and dried mixture, keep at 110°C for 30 minutes to decolorize, and filter to obtain decolorized oil. Heat the oil to 240°C, carry out deodorization under 2mbar and blowing nitrogen for 2h, and obtain the refined transesterification product A.

[0177] step 2

[0178]The product A100g obtained in step 1 is mixed with 200g of oleic acid (purity 78%) and then the dried mixture is passed through a packed bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com