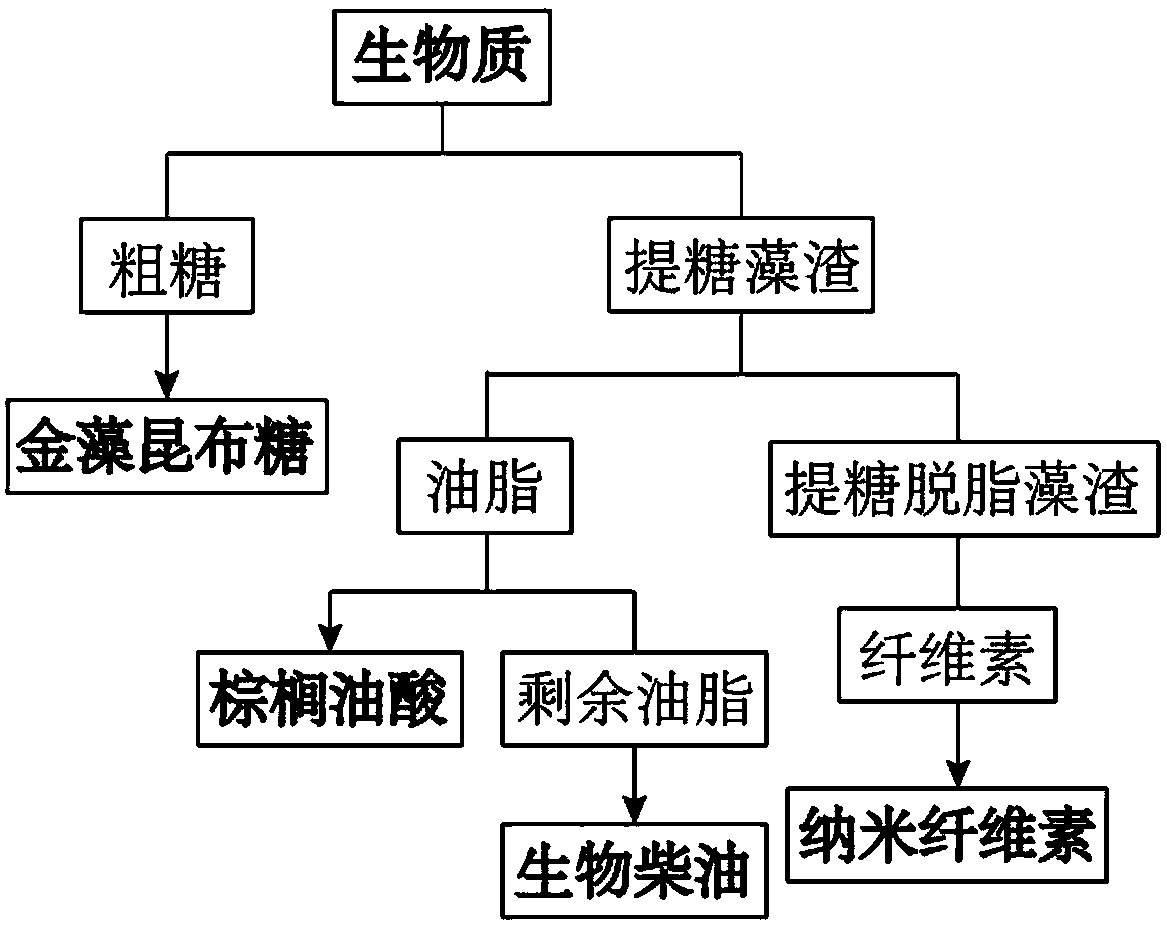

Method of utilizing tribonema to comprehensively refine biological product, biological diesel and biological material

A technology of biodiesel and yellow algae, applied in the direction of microorganism-based methods, biochemical equipment and methods, biofuels, etc., can solve the problems of unrealistic, restricting the commercial development of third-generation microalgae bioenergy, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

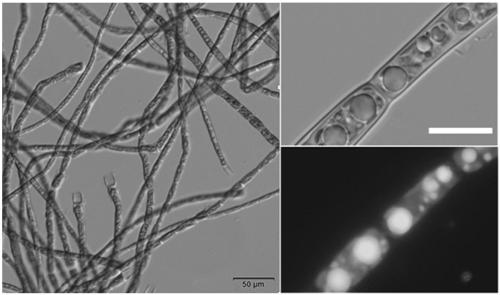

[0067] Embodiment 1: Filamentous microalgae - yellow silk algae (Tribonema sp.) culture

[0068] Inoculate the filamentous microalgae-Tribonema sp. algae preserved in the triangular flask into a columnar glass photobioreactor (length×inner diameter=60×6cm) (purchased from Guangzhou Genshui Experimental Equipment Co., Ltd.) Expansion and cultivation. The culture conditions are: mBG-11 liquid medium, temperature 25±1℃, continuous unilateral incandescent light (80~90μmol / m 2 / s), containing 1% CO 2 Compressed air blowing culture for 6 to 7 days. After the expansion cultivation, filter and harvest the algae through a sieve (300 mesh); The base was mBG-11 liquid medium, the initial concentration of sodium nitrate was set to 18mM, and the continuous unilateral concentration was 250μmol / m 2 / s light, other culture conditions are the same as above. After culturing for 15 days, measure the biomass, and filter through a sieve (300 mesh, pore size 48 μm) to harvest the wet algae mud...

Embodiment 2

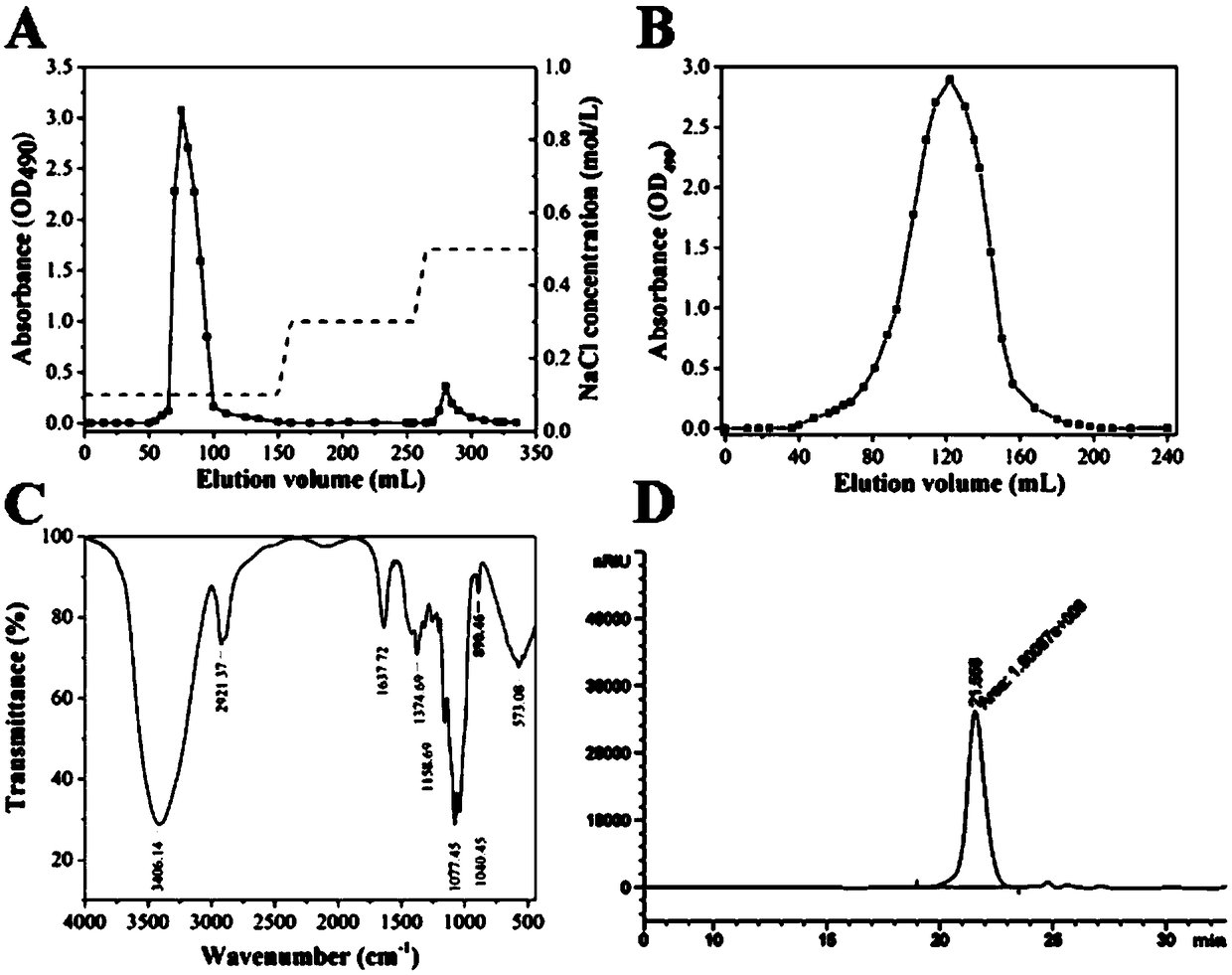

[0070] Embodiment 2: Extraction and separation of Chrysophylla laminarum sugar

[0071] Weigh a certain amount of dry algal powder obtained in Example 1 into a flask, and then suspend in 50 mM dilute sulfuric acid. The flask was placed in a constant temperature water bath at 80°C, and an electric stirrer was used to continuously stir and extract at 200rpm for 4h. After the extraction, the residual algae and the supernatant were separated by filtration through a silk sieve (300 mesh, pore size 48 μm), and the residual algae was extracted once more. The supernatants were combined, and 95% ethanol was added according to the ratio of v / v=1:4, and alcohol precipitation was carried out at 4°C for 12 hours. The harvested residual algae were washed with water and then dried in an oven at 60°C to obtain desugared algae residue, which was used for the extraction of total lipids. The alcohol-precipitated precipitate was obtained by centrifugation at 7500 rpm for 10 min, washed with eth...

Embodiment 3

[0073] Example 3: Extraction and enrichment of palmitoleic acid

[0074] (1) Extraction of total fat: after mixing the algae residue after sugar extraction obtained in Example 2 with 95% ethanol: n-hexane (v / v=1:1) according to the ratio of m / v=1:25, place Sonicate in an ultrasonic cleaner for 2 h. After ultrasonic treatment, the flask containing the mixed solution was placed in a constant temperature water bath at 50° C., and extracted with continuous stirring (200 rpm) by an electric stirrer for 6 h. After the extraction, filter the remaining algae residue through a sieve. Repeat the above step 3 to 4 times again until the algae residue turns off-white, and after the harvested supernatants are combined, remove the organic reagent in a rotary evaporator (50° C.) to obtain the total lipid extract. Detected by gas chromatography, the fatty acid composition in the total fat is mainly myristic acid (C14:0), palmitic acid (C16:0), palmitoleic acid (C16:1), oleic acid (C18:1), ei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com