Multiple quaternary ammonium salts clay interlaminar modifier and preparation method thereof

A multi-quaternary ammonium salt and clay layer technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of the limitation of interlayer distance peeling degree, single form of interlayer modifier, etc., to improve solubility The effect of suspension, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, preparation multi-quaternary ammonium salt type clay interlayer modifier

[0024] Put 32.4g (0.1mol) of ricinoleic acid into 15mL of xylene and 1.02g (0.01mol) of aluminum oxide into the reactor, after heating to 180°C, drop 5.3g of ricinoleic acid into the reaction solution with a dropping funnel (0.0515mol) of diethylenetriamine, the reaction is continuously separated by a water separator, stirred for 1.5hour, and evaporated to remove xylene to obtain bisamide;

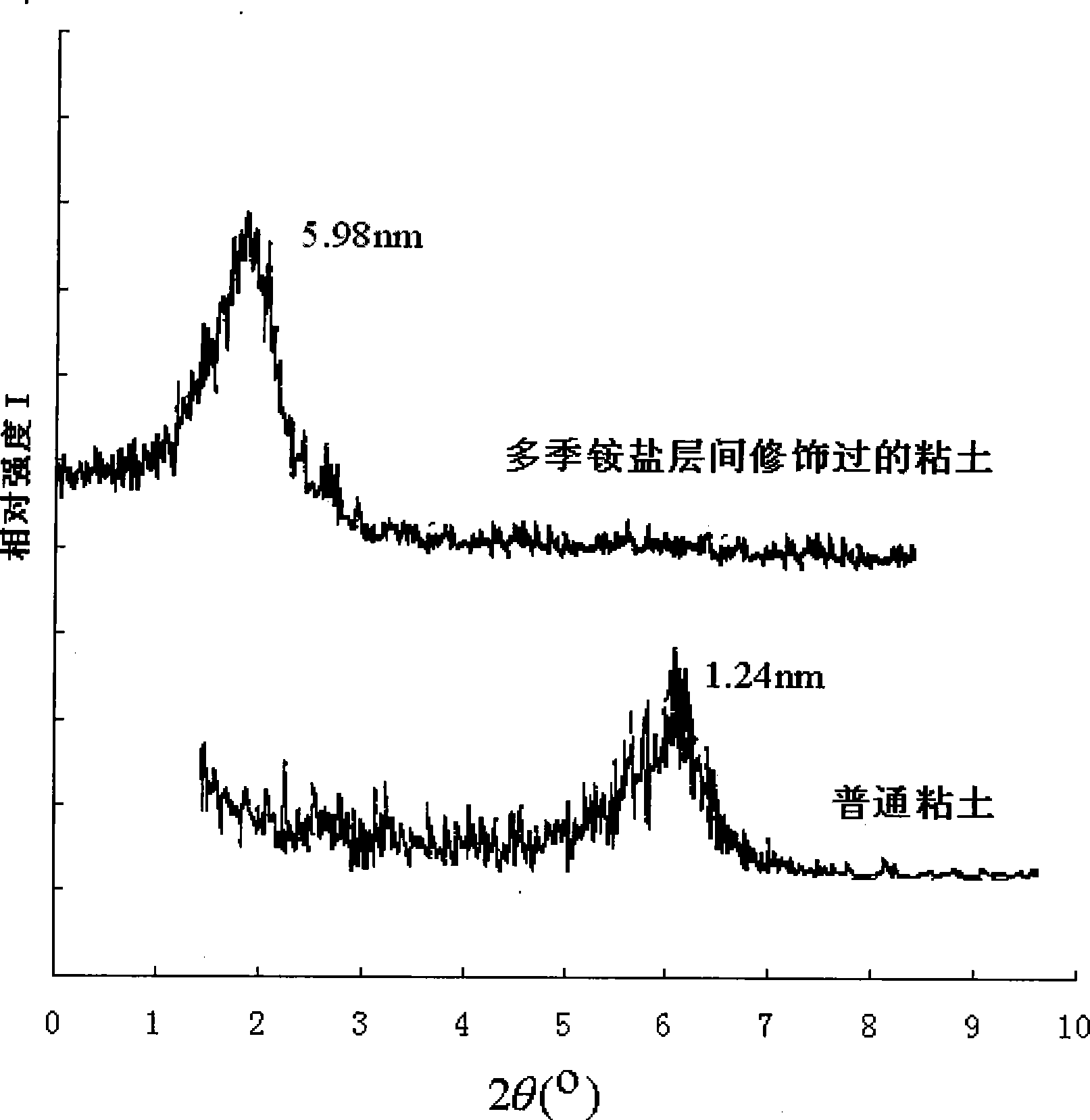

[0025] Add 43.6g (0.05mol) of bisamide and 12ml of ethanol into the reactor, heat to 30°C, and drop 23g (0.05mol) of 3-chloro-2-hydroxypropyltrimethyl into the reaction system with a dropping funnel Ammonium chloride solution, heated up to 70°C, stirred and reacted for 2 hours to obtain multi-quaternary ammonium salt type clay interlayer modifier. From attached figure 1 It can be seen that the distance between clay layers modified by this modifier increases from 1.24nm to 5.98nm.

Embodiment 2

[0026] Embodiment 2, preparation multi-quaternary ammonium salt type clay interlayer modifier

[0027] Put 32.4g (0.1mol) of ricinoleic acid into 15mL of xylene and 1.02g (0.01mol) of aluminum oxide into the reactor. After heating to 220°C, add 5.3g of ricinoleic acid dropwise to the reaction solution with a dropping funnel (0.0515mol) of diethylenetriamine, the reaction is continuously separated by a water separator, stirred for 2.5hours, and evaporated to remove xylene to obtain bisamides;

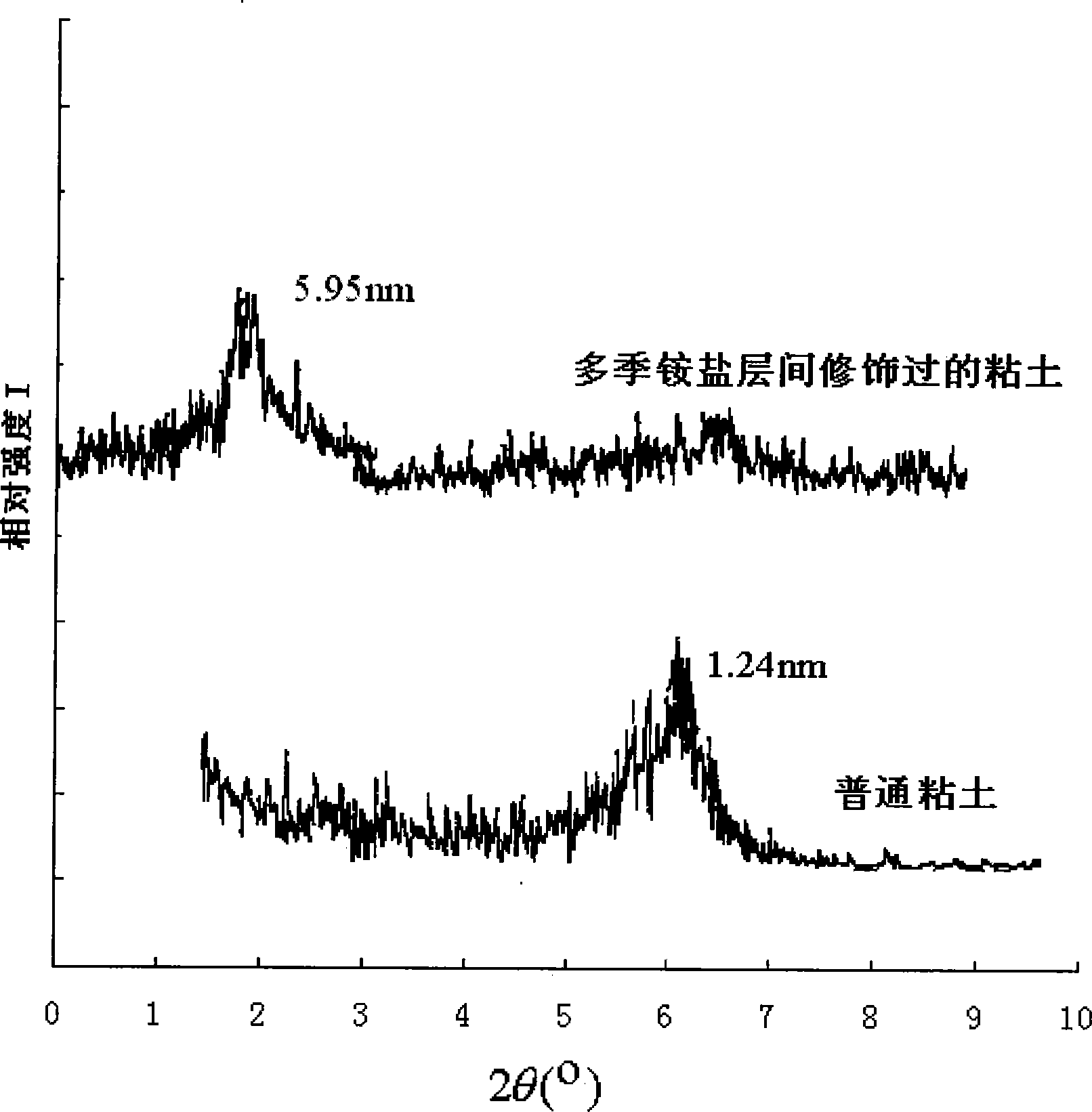

[0028] Add 43.6g (0.05mol) of bisamide and 12ml of ethanol into the reactor, heat to 40°C, and drop 23g (0.05mol) of 3-chloro-2-hydroxypropyltrimethyl into the reaction system with a dropping funnel The ammonium chloride solution was heated to 80° C., stirred and reacted for 4 hours to obtain a multi-quaternary ammonium salt-type clay interlayer modifier. From attached figure 2 It can be seen that the distance between clay layers modified by this modifier increases from 1.24nm to 5.95...

Embodiment 3

[0029] Embodiment 3, preparation multi-quaternary ammonium salt type clay interlayer modifier

[0030] Put 32.4g (0.1mol) of ricinoleic acid into 15mL of xylene and 1.02g (0.01mol) of boric acid into the reactor, after heating to 200°C, add 5.3g (0.0515mol) of ) of diethylenetriamine, the reaction was continuously separated through a water separator, stirred for 2.0 hours, evaporated to remove xylene, and obtained bisamide;

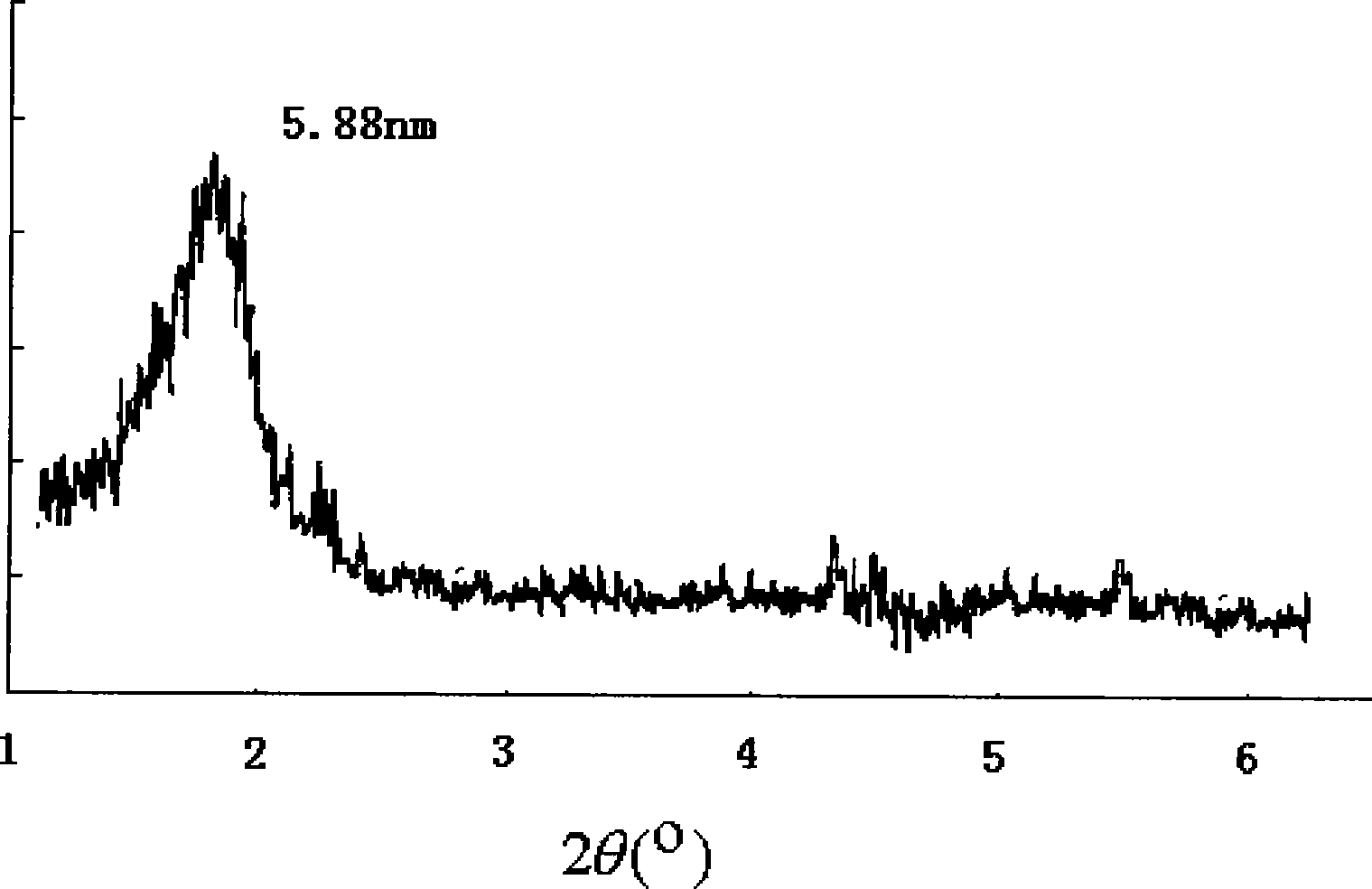

[0031] Add 43.6g (0.05mol) of bisamide and 12ml of ethanol into the reactor, heat to 35°C, and drop 23g (0.05mol) of 3-chloro-2-hydroxypropyltrimethyl into the reaction system with a dropping funnel Ammonium chloride solution, heated up to 75°C, stirred for 3 hours to obtain multi-quaternary ammonium salt type clay interlayer modifier, as attached image 3 , the interlayer distance of clay modified with this modifier is 5.88nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com