Fish scaling and slicing all-in-one machine

An all-in-one machine and fish technology, which is applied in the fields of slicing fish, cleaning/descaling fish, and processing fish, etc. It can solve the problems of inaccurate knife setting and uneven cutting of the slicing knife, and achieve the descaling rate High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

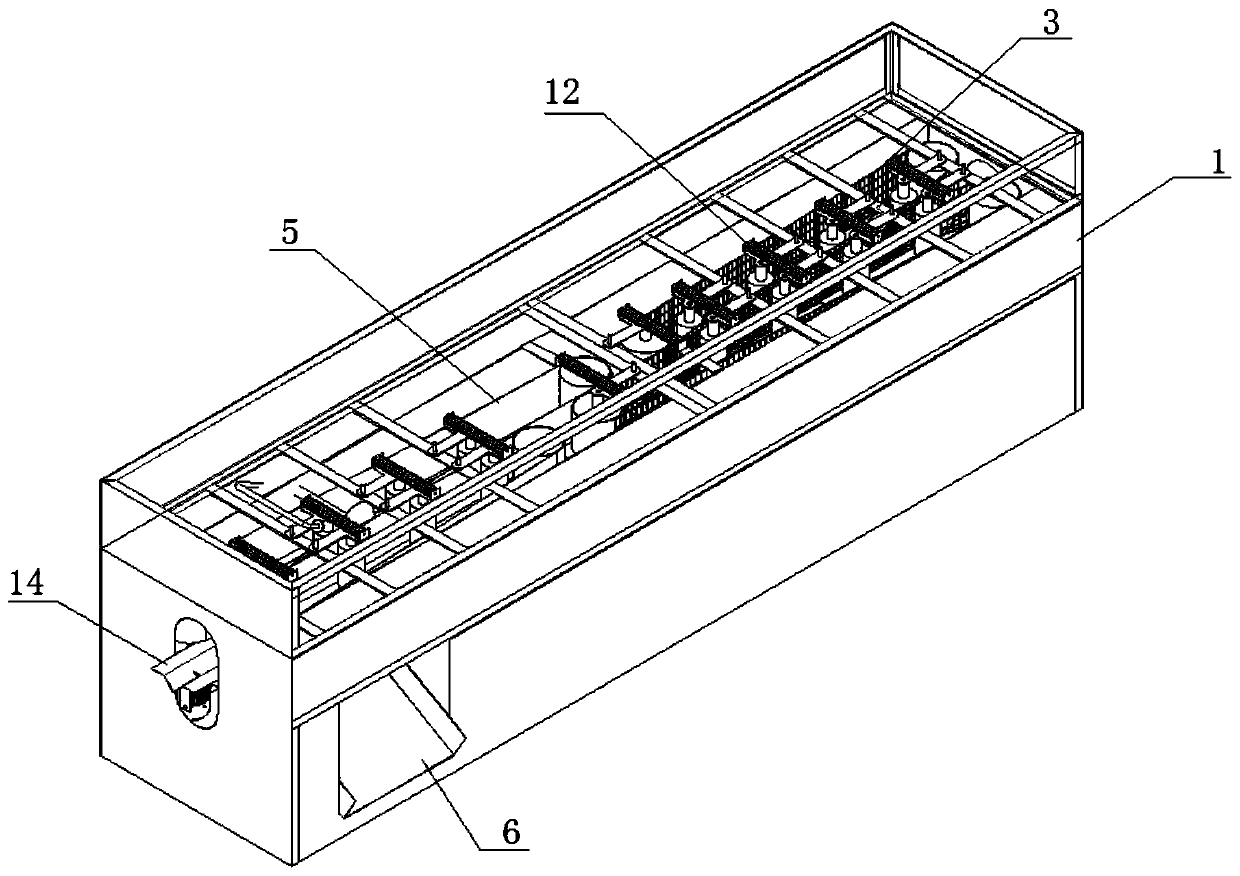

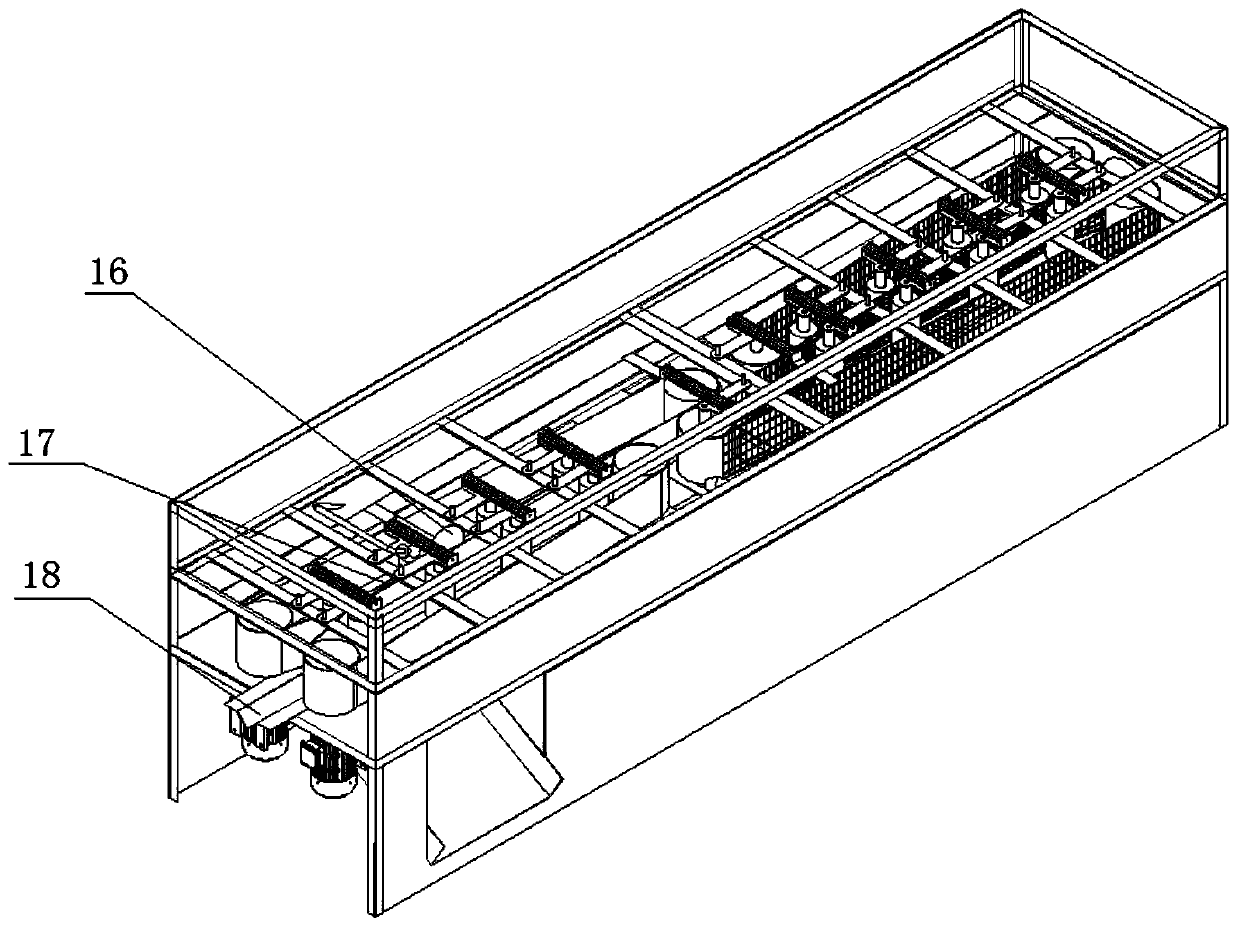

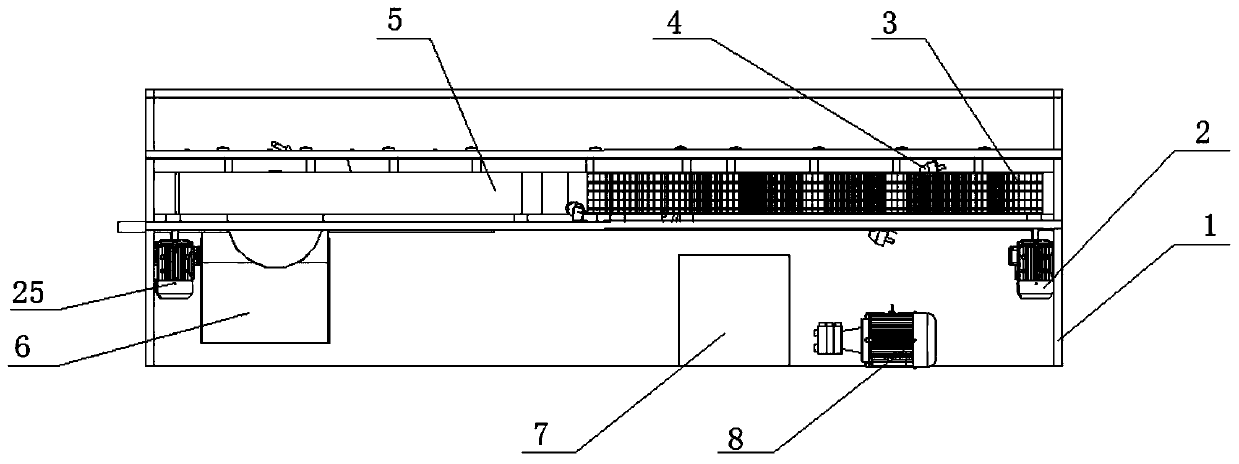

[0036] Attached below Figure 1-Figure 5 The present invention is described in detail, specifically, the structure is as follows:

[0037] This embodiment provides an all-in-one fish descaling and flaking machine, including a frame 1 and a descaling transmission mechanism installed inside the frame 1, and a descaling transmission mechanism, and the descaling transmission mechanism and the descaling transmission mechanism are respectively connected and driven device. In this embodiment, the driving device of the descaling transmission mechanism is the descaling power source motor 2 , and the driving device of the sheet opening transmission mechanism is the sheet opening power source motor 25 .

[0038] A guide groove 18 for guiding the fish body is provided below the descaling conveying mechanism and the sheet-opening conveying mechanism. One end of the guide groove 18 forms a fish body inlet 13 and the other end forms a fish fillet outlet 14 . The fish body after the head re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com