A compound acid descaling and derusting cleaning agent

A rust-removing cleaning agent and acid technology, applied in the field of descaling and rust-removing agents, can solve the problems of secondary corrosion of metal surface, affecting the service life of equipment, incomplete cleaning, etc., to avoid microbial sludge, avoid insufficient cleaning time, Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

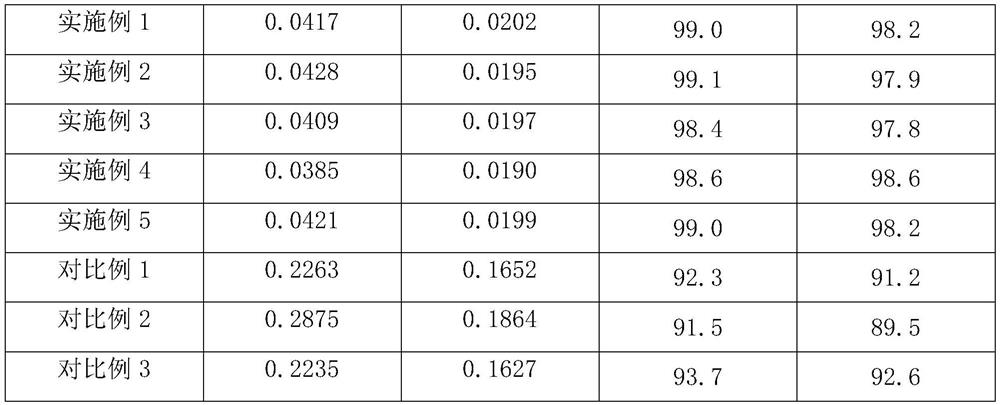

Embodiment 1

[0033] Embodiment 1: A kind of composite acidic descaling and descaling cleaning agent, with conventional mixing and agitating mode, the mass percentage is successively mixed with 19.9% deionized water, 70% acid, 3% wetting agent, 0.1% color code indicator, 6 % complexing agent and 1% corrosion inhibitor are added into the mixing tank and mixed evenly to obtain a compound acidic descaling and descaling pickling agent.

[0034] By mass percentage, in the present embodiment:

[0035] The acid uses hydrochloric acid with a concentration of 31%, the complexing agent uses hydroxyethylidene diphosphonic acid, the corrosion inhibitor uses hexamethylenetetramine, the wetting agent uses LF901 surfactant, and the color code indicator uses methyl red.

Embodiment 2

[0036] Embodiment 2: A kind of composite acidic descaling and descaling cleaning agent, with conventional mixing and stirring mode, the mass percent is successively mixed with 19.9% deionized water, 70% acid, 3% wetting agent, 0.1% color code indicator, 5 % complexing agent and 2% corrosion inhibitor are added into the mixing tank and mixed evenly to obtain a compound acidic descaling and descaling pickling agent.

[0037] By mass percentage, in the present embodiment:

[0038]The acid uses hydrochloric acid with a concentration of 31%, the complexing agent uses 2-phospho-1,2,4-tricarboxylic acid butane, the corrosion inhibitor uses thiourea, and the wetting agent uses Lutensol XL 80 surfactant, color code The indicator uses methyl red.

Embodiment 3

[0039] Embodiment 3: A kind of composite acidic descaling and descaling cleaning agent, the mass percentage is successively mixed with conventional mixing and stirring mode to be 65.4% deionized water, 25% acid, 3% wetting agent, 0.1% color code indicator, 5% % complexing agent and 1.5% corrosion inhibitor are added into the mixing tank and mixed evenly to obtain a compound acidic acid cleaning agent for descaling and rust removal.

[0040] By mass percentage, in the present embodiment:

[0041] The acid is sulfamic acid, the complexing agent is ethylenediamine tetramethylene phosphonic acid, the corrosion inhibitor is thiourea, the wetting agent is Plurafac LF221 surfactant, and the color code indicator is methyl red.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com