Method for cleaning scale on fins of plate type heat exchanger

A plate heat exchanger, scale cleaning technology, applied in the direction of vibration cleaning, hearth furnace, cleaning heat transfer devices, etc., can solve the problems of staff and working environment injury, affecting the heat exchange efficiency of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0017] The application principle of the present invention will be further described below with reference to specific embodiments.

[0018] A method for cleaning scale of plate heat exchanger fins, comprising the following steps:

[0019] a) Place the scaled side of the plate heat exchanger fins on a sunny ground for sunlight;

[0020] b) When the scale on the fins appears dry cracks, lift the fins and beat them on the rubber pad, the scale will fall off by itself, rinse with clean water and then reuse.

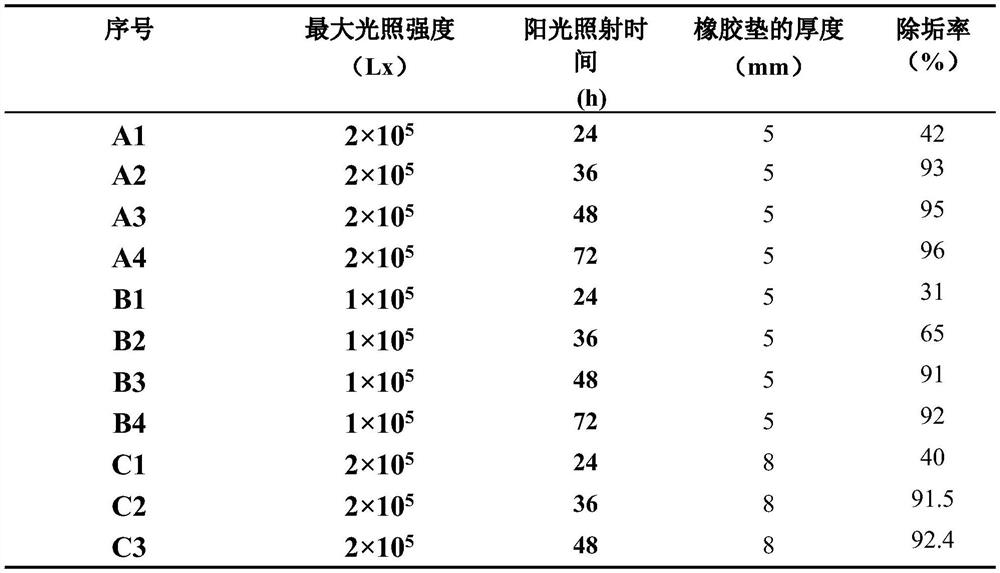

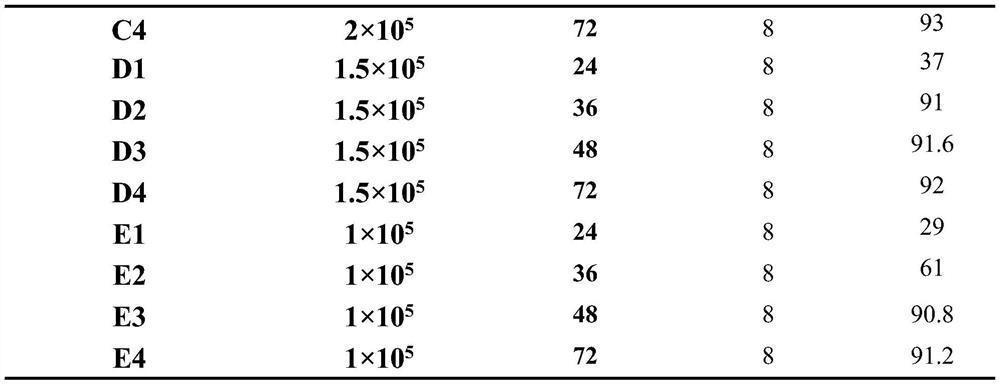

[0021] The present invention selects five plate heat exchanger fins and divides them into five groups A, B, C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| descaling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com