A method for cleaning ash and slag on convection section fins of steam injection boiler

A technology of steam injection boiler and convection section, which is applied in combustion methods, chemical instruments and methods, detergent compositions, etc., can solve the problems of incomplete combustion, poor heat exchange effect, flue blockage, etc., and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] This embodiment provides a method for cleaning ash and slag on fins in the convection section of a steam injection boiler.

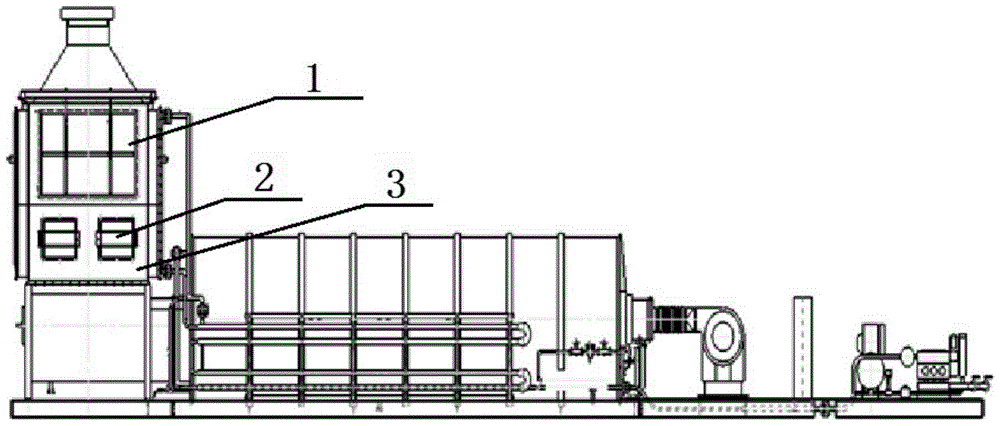

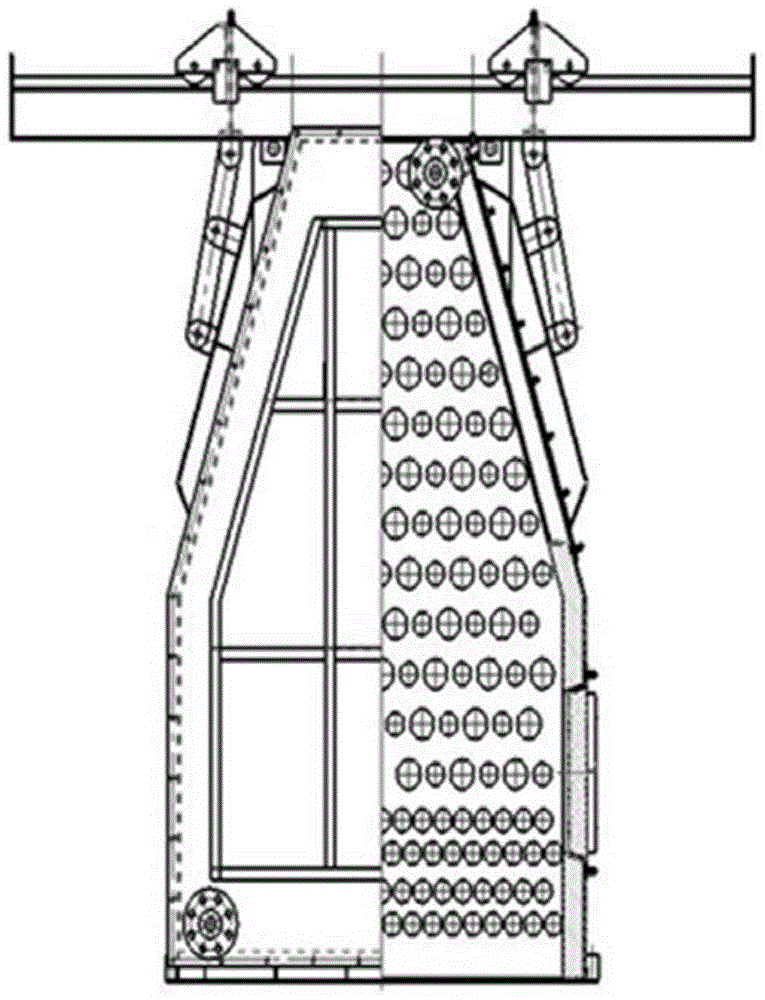

[0033] The steam injection boiler of this embodiment is a steam injection boiler for oil fields, such as figure 1 and figure 2 As shown, it belongs to a once-through boiler, and the convection section 1 is equivalent to the economizer of the boiler, which is installed at the flue gas discharge, and its structure is a finned tube of a fork row.

[0034] The method for cleaning the soot deposits on the fins of the convection section of the steam injection boiler in this embodiment includes the following steps:

[0035] Open the side plate of the convection section, air cleans the dust, and removes the floating ash in the convection section;

[0036] Cover the side panel of the convection section 1 with a waterproof cloth, lay a waterproof cloth under the bottom fin of the convection section 1, and place the water receiving tank;

[0037] Open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com