EDTA (Ethylene Diamine Tetraacetic Acid) disodium salt compound surfactant

A technology of surfactant and disodium salt, applied in the directions of surface active detergent composition, nonionic surface active compound, detergent composition, etc., can solve the problems of high cost, large amount of added, limited use, etc. The effect of low manufacturing cost, improved descaling rate, and reduced descaling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

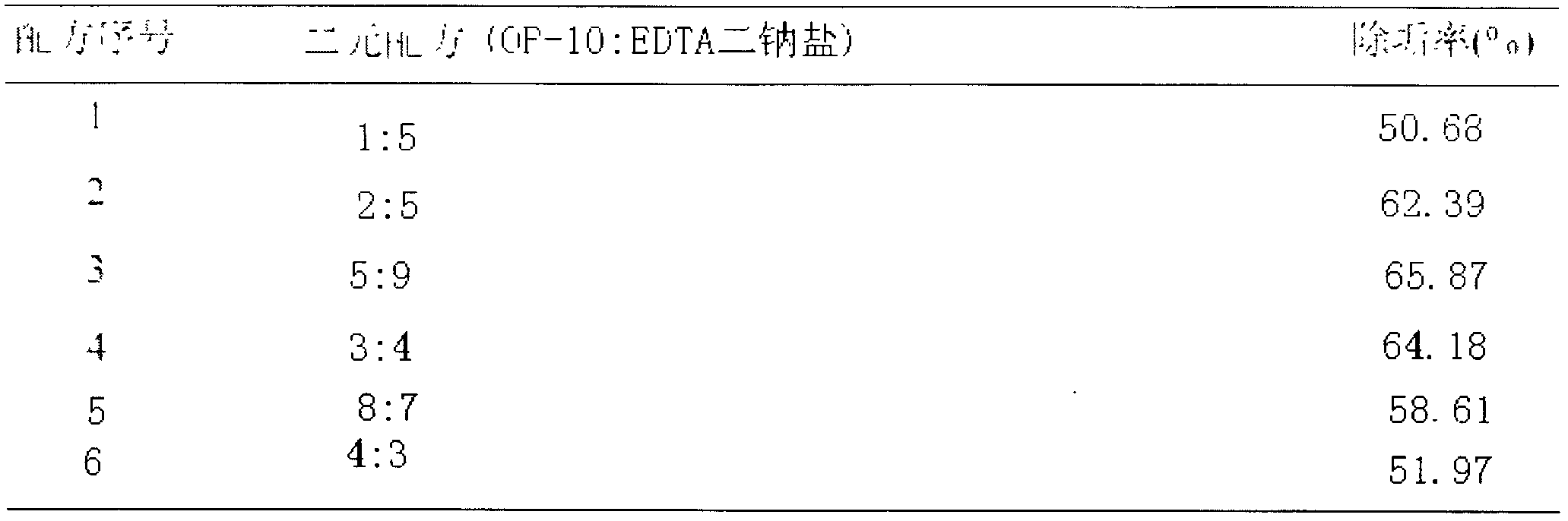

[0018] A kind of EDTA disodium salt complex surfactant that the present invention relates to is mixed by OP-10 and EDTA disodium salt, and by mass, the ratio of described OP-10 and EDTA disodium salt is 2: 5~ 4:3.

[0019] Weigh the strontium sulfate scale, drop OP-10 and EDTA disodium salt into the marked Erlenmeyer flask respectively according to the formula, shake well, dissolve in warm water for 5 minutes, adjust the pH value to 12 with NaOH solution, and adjust the temperature of the water bath to 60°C, react for 24 hours, after the reaction, the recorded data is shown in the table below:

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com