Descaling agent for leachate anaerobic system and preparation method of descaling agent

A technology of descaling agent and leachate, which is applied in the field of landfill leachate treatment, can solve the problems of destroying anaerobic reaction, local overheating of blocked pipes, etc., and achieve the effect of avoiding blockage of pipe network, accelerating cleaning, and preventing surface corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

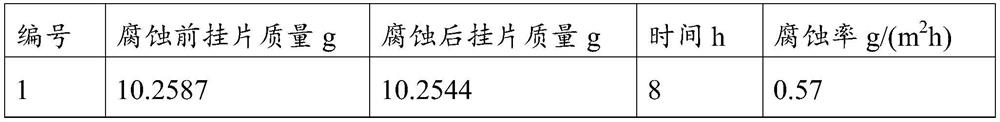

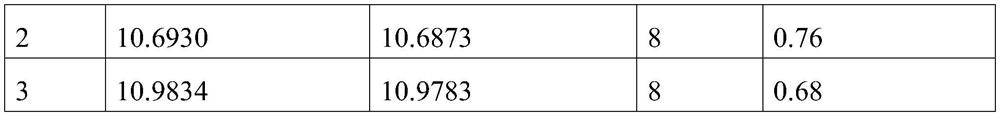

Embodiment 1

[0030] A scale remover for leachate anaerobic system, comprising the following raw materials in parts by weight:

[0031] 5 parts hydrochloric acid

[0032] 1 part citric acid

[0033] EDTA 1 part

[0034] Amino trimethylene phosphonic acid 0.4 parts

[0035] Hydroxyethylidene diphosphonic acid 0.3 parts

[0036] 0.2 parts of polymaleic acid

[0037] Sodium dodecyl sulfonate 0.3 parts

[0038] Sodium hexametaphosphate 0.9 parts

[0039] 45 parts of water

[0040] The preparation method of present embodiment descaling agent comprises the following steps:

[0041] S1: Put water in a container, heat it to 70°C with a jacketed heat source, then add citric acid, aminotrimethylene phosphonic acid, EDTA, hydroxyethylidene diphosphonic acid, polymaleic acid, dodecyl sulfonate in sequence sodium hexametaphosphate, sodium hexametaphosphate, stirred until there is no precipitation, cooled to room temperature, and set aside;

[0042] S2: adding hydrochloric acid to the solution p...

Embodiment 2

[0044] A scale remover for leachate anaerobic system, comprising the following raw materials in parts by weight:

[0045] 8 parts hydrochloric acid

[0046] 3 parts citric acid

[0047] EDTA 2 parts

[0048] Amino trimethylene phosphonic acid 1 part

[0049] Hydroxyethylidene diphosphonic acid 0.5 parts

[0050] 0.6 parts of polymaleic acid

[0051] Sodium dodecyl sulfonate 0.4 parts

[0052] Sodium hexametaphosphate 1.2 parts

[0053] 84 parts of water

[0054] The preparation method of present embodiment descaling agent comprises the following steps:

[0055] S1: Put water in a container, heat it to 70°C with a jacketed heat source, then add citric acid, aminotrimethylene phosphonic acid, EDTA, hydroxyethylidene diphosphonic acid, polymaleic acid, dodecyl sulfonate in sequence sodium hexametaphosphate, sodium hexametaphosphate, stirred until there is no precipitation, cooled to room temperature, and set aside;

[0056] S2: adding hydrochloric acid to the solution pr...

Embodiment 3

[0058] A scale remover for leachate anaerobic system, comprising the following raw materials in parts by weight:

[0059] 12 parts hydrochloric acid

[0060] 4 parts citric acid

[0061] EDTA 4 parts

[0062] Amino trimethylene phosphonic acid 2.5 parts

[0063] Hydroxyethylidene diphosphonic acid 1.6 parts

[0064] 0.8 parts of polymaleic acid

[0065] Sodium dodecyl sulfonate 0.5 parts

[0066] Sodium hexametaphosphate 1.5 parts

[0067] 135 parts of water

[0068] The preparation method of present embodiment descaling agent comprises the following steps:

[0069] S1: Put water in a container, heat it to 70°C with a jacketed heat source, then add citric acid, aminotrimethylene phosphonic acid, EDTA, hydroxyethylidene diphosphonic acid, polymaleic acid, dodecyl sulfonate in sequence sodium hexametaphosphate, sodium hexametaphosphate, stirred until there is no precipitation, cooled to room temperature, and set aside;

[0070] S2: adding hydrochloric acid to the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com