Scale inhibitor and descaling agent and preparation method thereof

A scale remover and anti-scaling technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of short validity period of scale inhibitors and scale removers, aggravated corrosion of downhole tools, complicated on-site construction technology, etc. Good descaling effect, short descaling time, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

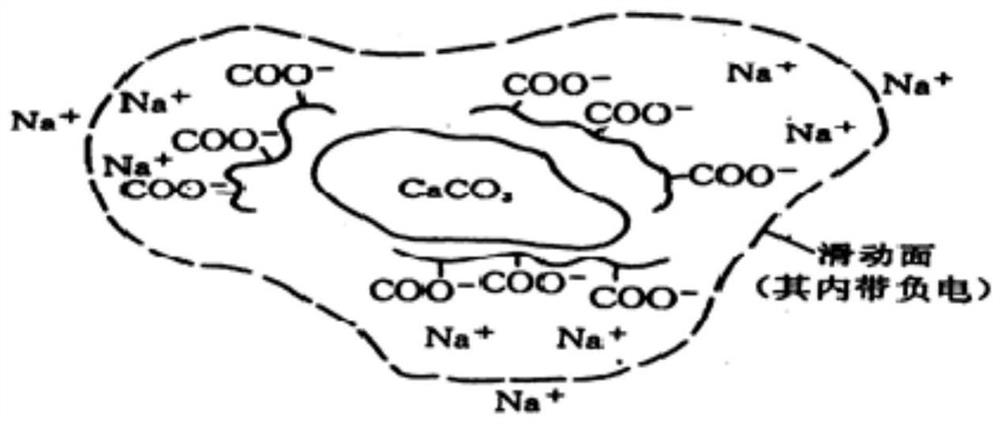

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] On the other hand, the embodiment of this application provides a method of preparation of scale -resistant and dirt, which is used to prepare the above -mentioned one of the dirt and division agent. This method includes:

[0051] According to the weight of each component, the reference time is added after adding water, anti-infrastructure, and stuning agent in turn. Salva removal agent.

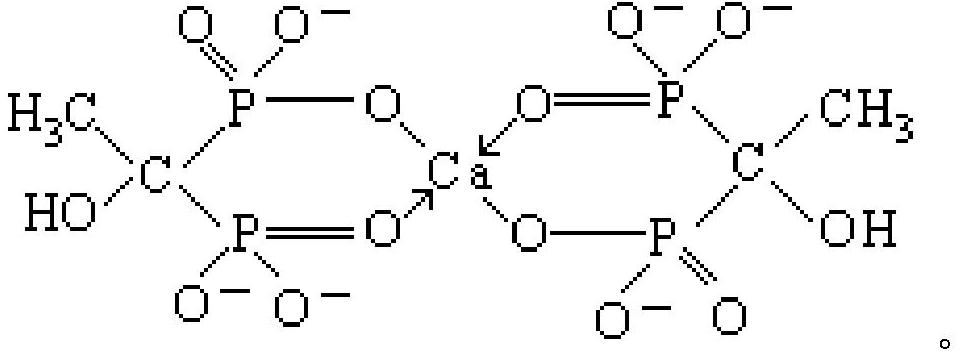

[0052] Furthermore, the amount of water consumption is 98.271-98.944 part of the water as the base solution. Sodium), stir for 10 minutes, add 0.004-0.006 sulfur ether, 0.004-0.005 parts of methylated single-scale polyamine, 0.005-0.01 parts of hydrolyzed polymeric anhydride, 0.01-0.02 parts of carboxyl anecidal ethylenevyl two-based ethylenevylvida ethylvida Phosphate, 0.15-0.4 parts of sodium dulate, and stirred for 5-10 minutes to obtain a dirt removal agent.

Embodiment 1

[0055] Take 98.271 parts of water as a base solution, add 0.2 part of potassium chloride, then add 0.004 sodium sodium salt, 0.005 parts of glucose acid potassium, stir for 10 minutes, then add 0.004 sulfur ether, 0.004 0.004 Paquerized monocular polyamine, 0.005 parts of hydrolyzed polymeric anhydride, 0.01 parts carboxyl anethinyl phosphate, 0.15 part of sodium dulate benzene sodium, stir for 5 minutes to obtain dirt and dirt removable agent Essence

Embodiment 2

[0057] Take 98.271 parts of water as a base solution, add 0.2 part of potassium chloride, then add 0.004 sodium sodium salt, 0.006 copies of glucose acid potassium, stir for 10 minutes, and then add 0.006 sulfur ether, 0.004 0.004 Paquerized monocular polyamine, 0.008 part of hydrolyzed polymeric anhydride, 0.01 part of carboxyl anethinyl phosphate, 0.2 sodium dulate benzene sulfate, stir for 6 minutes to obtain dirt and dirt removal agent Essence

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com