Surfactant and chelating agent ternary compound descaling agent

A surfactant and chelating agent technology, applied in the direction of surface active detergent composition, detergent composition, chemical instruments and methods, etc., can solve the problems of large amount of addition, limited use, high cost, etc., and achieve descaling rate Improvement, reduction of descaling cost, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

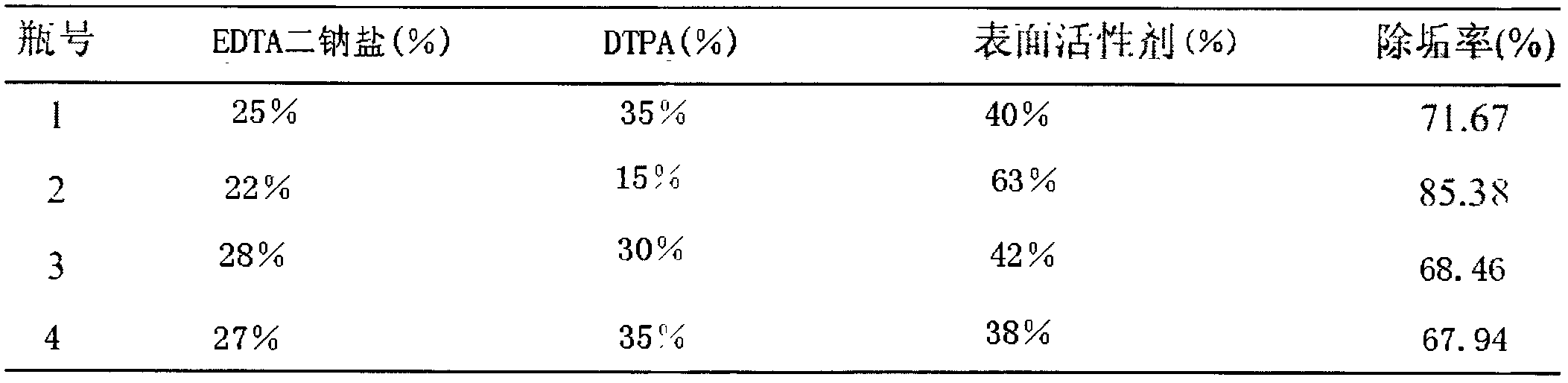

[0026] The present invention relates to a surfactant and chelating agent ternary compound descaling agent, which is formed by mixing OP-10, EDTA disodium salt and DTPA. According to mass percentage, the EDTA disodium salt accounts for 20%~ 30%, DTPA accounts for 10% to 40%, and the balance is OP-10.

[0027] In order to obtain the best formula, the present invention has done an experiment. In the experiment, 0.5000 g of barium sulfate scale was weighed, the pH value was 12, the temperature of the water bath was adjusted to 60° C., and the reaction was carried out for 24 hours. After the reaction, the recorded data are shown in the following table:

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com