Electrolytic descaling device for circulating water treatment of ship boiler

A circulating water and boiler technology, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., can solve problems such as reducing the strength of the furnace, complicated operation, and increased heat transfer resistance. Achieve the effects of improving space utilization, reducing device volume, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

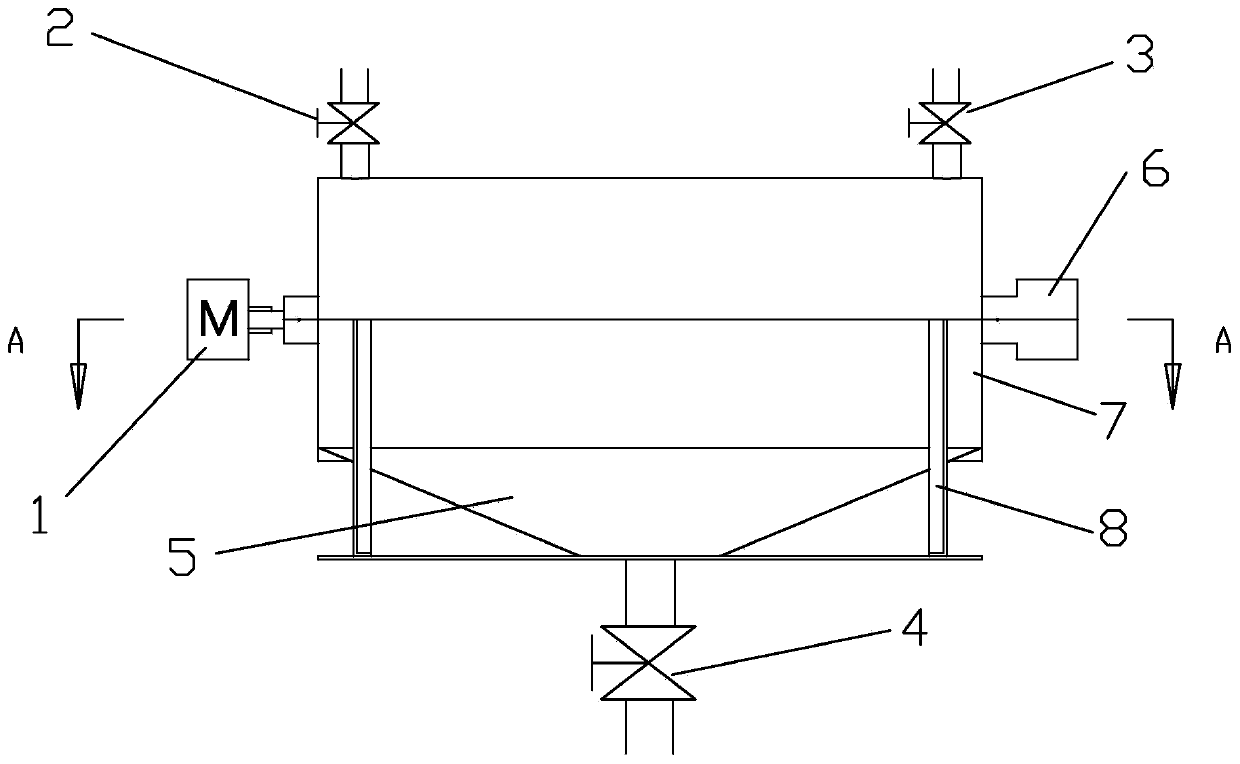

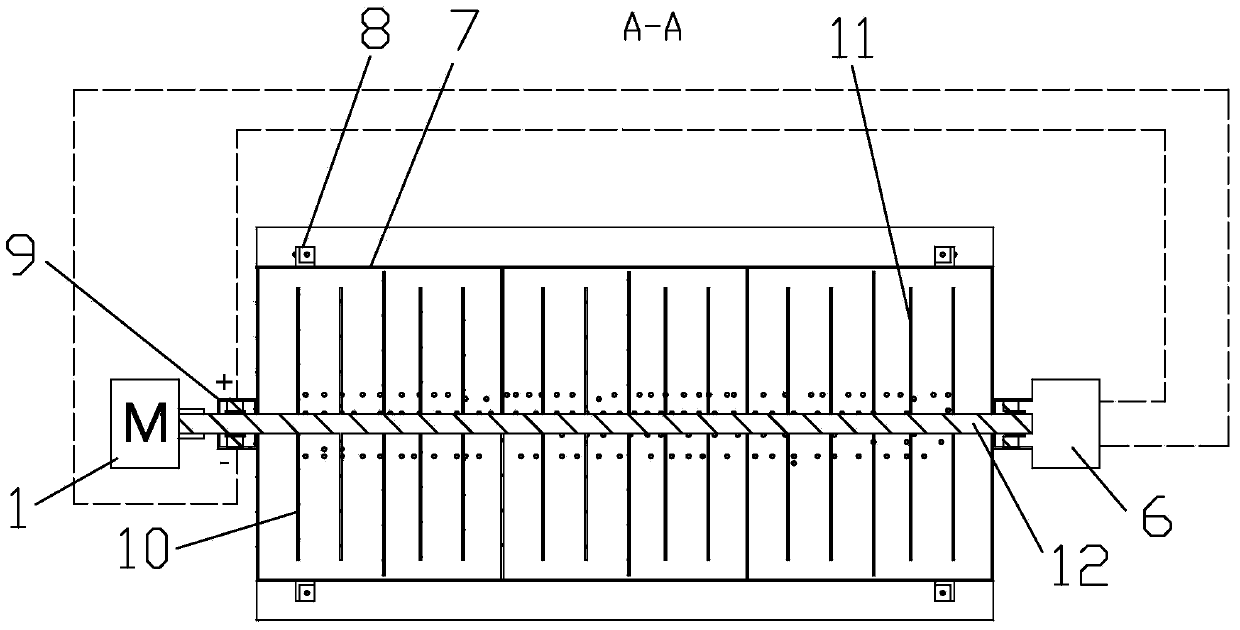

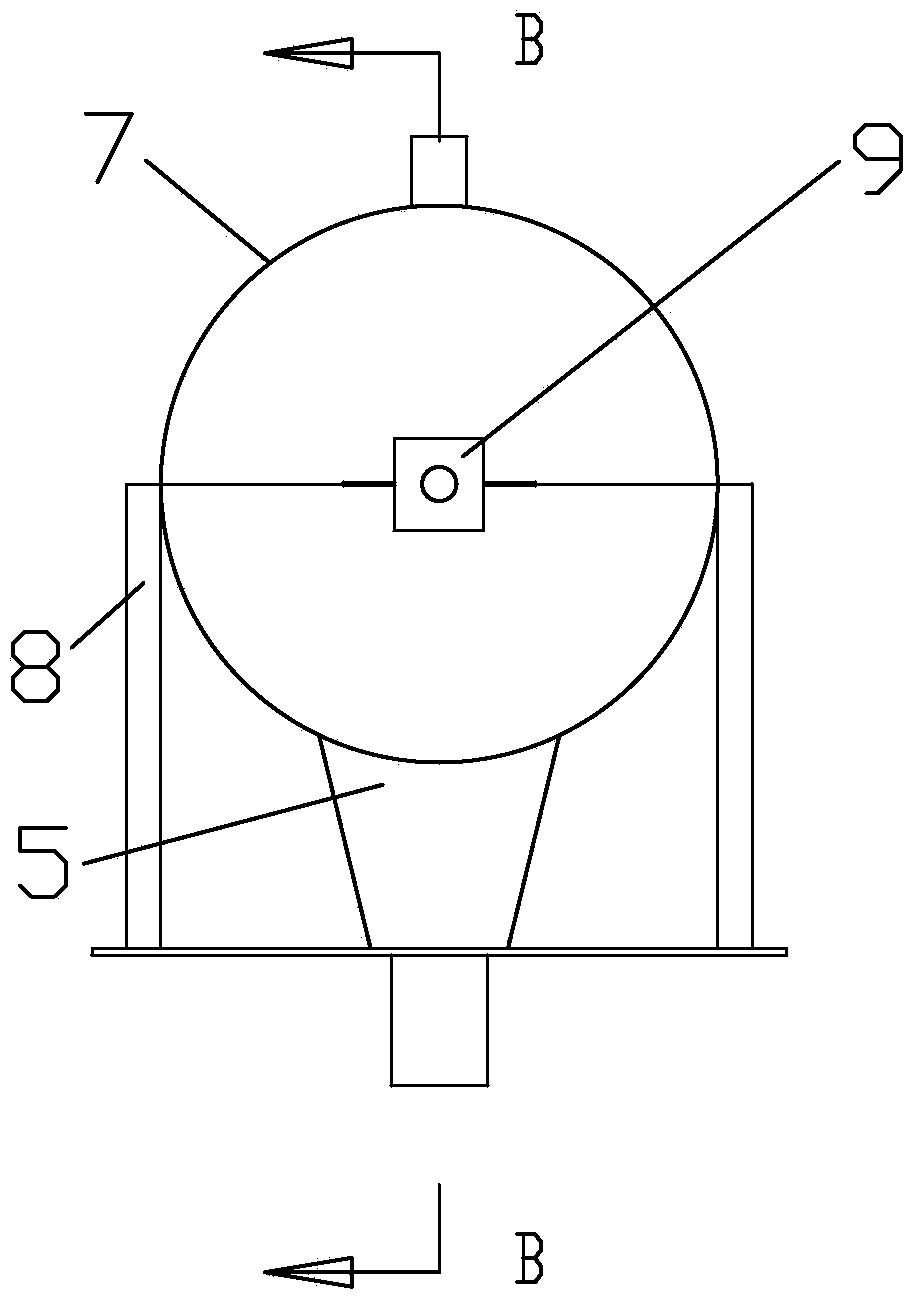

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings. like Figure 1-5 As shown, an electrolytic descaling device for the treatment of circulating water in ship boilers includes a geared motor 1, a water inlet valve 2, a water outlet valve 3, a sewage valve 4, a commutator 9, a scraper 13, and a disc-type flat electrode 10 , sedimentation tank 5, conductivity detection electrode 11, scale controller 6, cylindrical barrel 7, sedimentation tank 5, rotating shaft 12, carbon brush 14, slip ring 15 and shaft sleeve 16;

[0029] The rotating shaft 12 is installed on the center line of the cylindrical barrel 7 through bearings, one end of the rotating shaft 12 is connected with the geared motor 1, and the other end is connected with the scale controller 6; the geared motor 1 drives the rotating shaft 12 to slowly rotate, thereby Drive the disc-type flat electrode 10 to rotate slowly;

[0030] The bottom of the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com