Reverse osmosis membrane assembly continuous cleaning device, and method utilizing device for reverse osmosis membrane assembly cleaning

A technology of reverse osmosis membrane components and cleaning devices, which is applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc. It can solve the problems of membrane surface damage, waste of chemical reagents, and large amount of clean water, etc., and achieve an increase in automation , Save cleaning time and improve cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

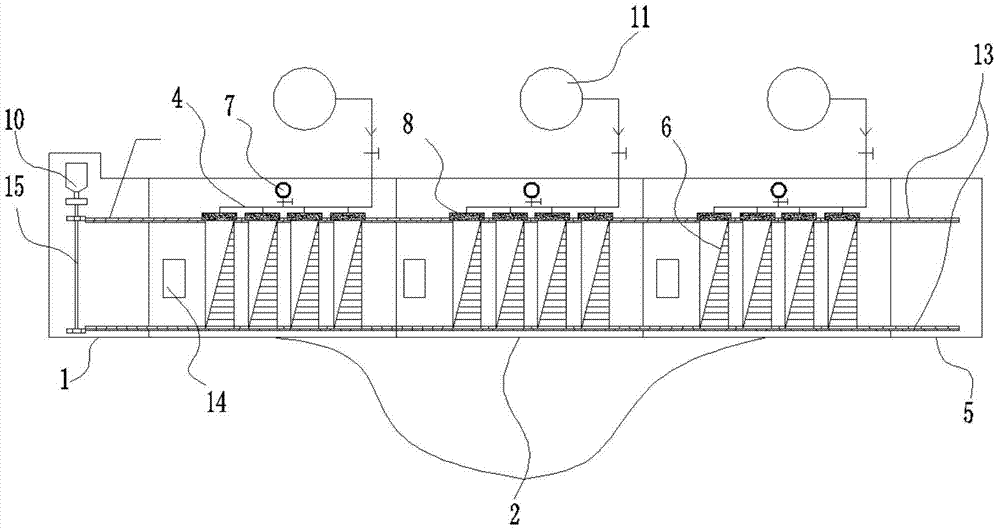

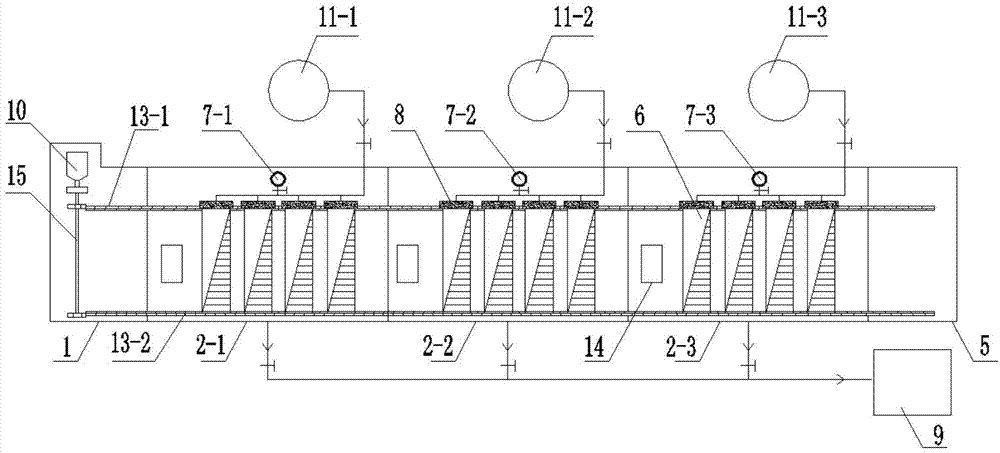

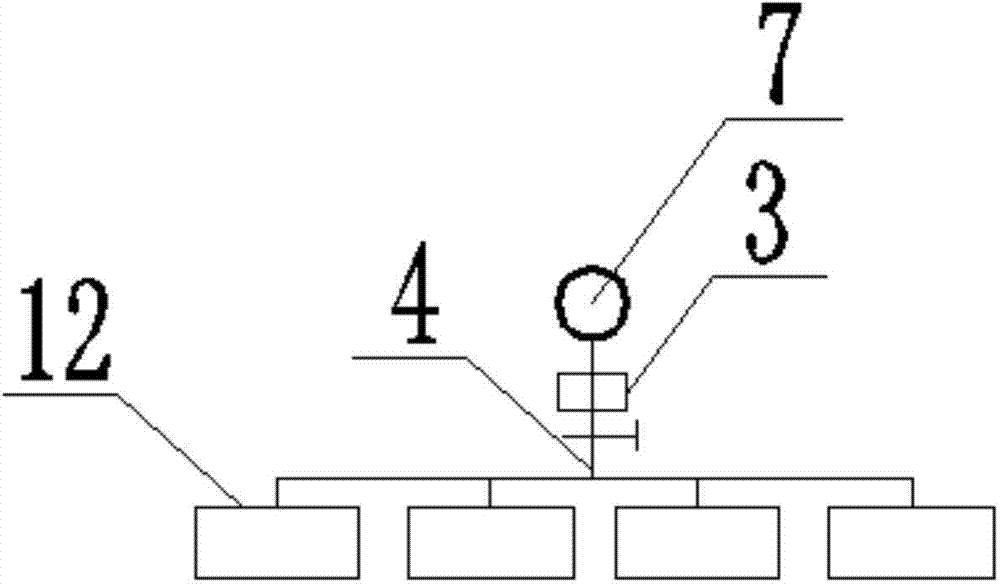

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a continuous off-line cleaning device for reverse osmosis membrane components includes: cleaning tanks 2 for soaking and cleaning reverse osmosis membrane components 6, the cleaning tanks 2 have several and are independent of each other; It is equipped with different cleaning fluids; it also includes a driving transmission device for driving the reverse osmosis membrane components to be continuously cleaned in mutually independent cleaning tanks. The driving transmission device includes a motor 10, a rotating shaft 15 and a chain 13. The motor 10 drives the chain to rotate through the driving rotating shaft 15, and the reverse osmosis membrane module 6 is connected to the chain. The chain 13 is a double chain, including a first chain 13-1 and a second chain 13-2, and the reverse osmosis membrane module 6 is detachably connected between the double chains. In order to achieve better cleaning...

Embodiment 2

[0048] combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , taking the use of 3 cleaning tanks as an example, the method for cleaning the reverse osmosis membrane module using the equipment of Example 1 is described in detail, as follows:

[0049] 1) In the installation area 1, fix the first batch of reverse osmosis membrane modules 6 on the inner side of the double chain 13 with a clamp 8, turn on the motor 10, and the motor 10 drives the first chain 13-1 and the second chain 13 through the rotating shaft 15 -2 synchronous movement, while the first batch of reverse osmosis membrane modules 6 also move together, when the first batch of reverse osmosis membrane modules 6 moves to the middle position of the first cleaning tank 2-1, stop the motor 10, open the reverse osmosis membrane module The clamp 8 on one side of the 6 seals the cleaning end cover 12 with the reverse osmosis membrane assembly 6, and then uses the clamp 8 to fix the cleaning end cover 12 a...

Embodiment 3

[0061] A factory uses a reverse osmosis system as a pre-desalination process. It uses self-provided well water as the treatment water source. After pretreatment, it enters the reverse osmosis device. The system is a one-stage two-stage reverse osmosis device with a total of 5 sets of reverse osmosis devices, and the water production capacity is 500t / h, the membrane module is American DOW Dow RO reverse osmosis membrane; after two years of operation of the system, the water production rate has decreased, and the system pressure and pressure difference have increased. In order to meet the production requirements of the enterprise, the polluted reverse osmosis membrane module After disassembly, the continuous off-line cleaning technology and equipment of the present invention are used to clean the membrane module to improve the operation effect of the reverse osmosis system. Three cleaning tanks are used, and the method is the same as in Example 2. First of all, according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com