Forming method of non-planar polyurethane screen meshes

A technology of polyurethane sieve and forming method, which is applied in the field of forming non-planar polyurethane screen, which can solve the problems of low porosity, high water content of materials, and failure of mineral classification to meet the requirements, so as to achieve high porosity and increase sieve The effect of sub-area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

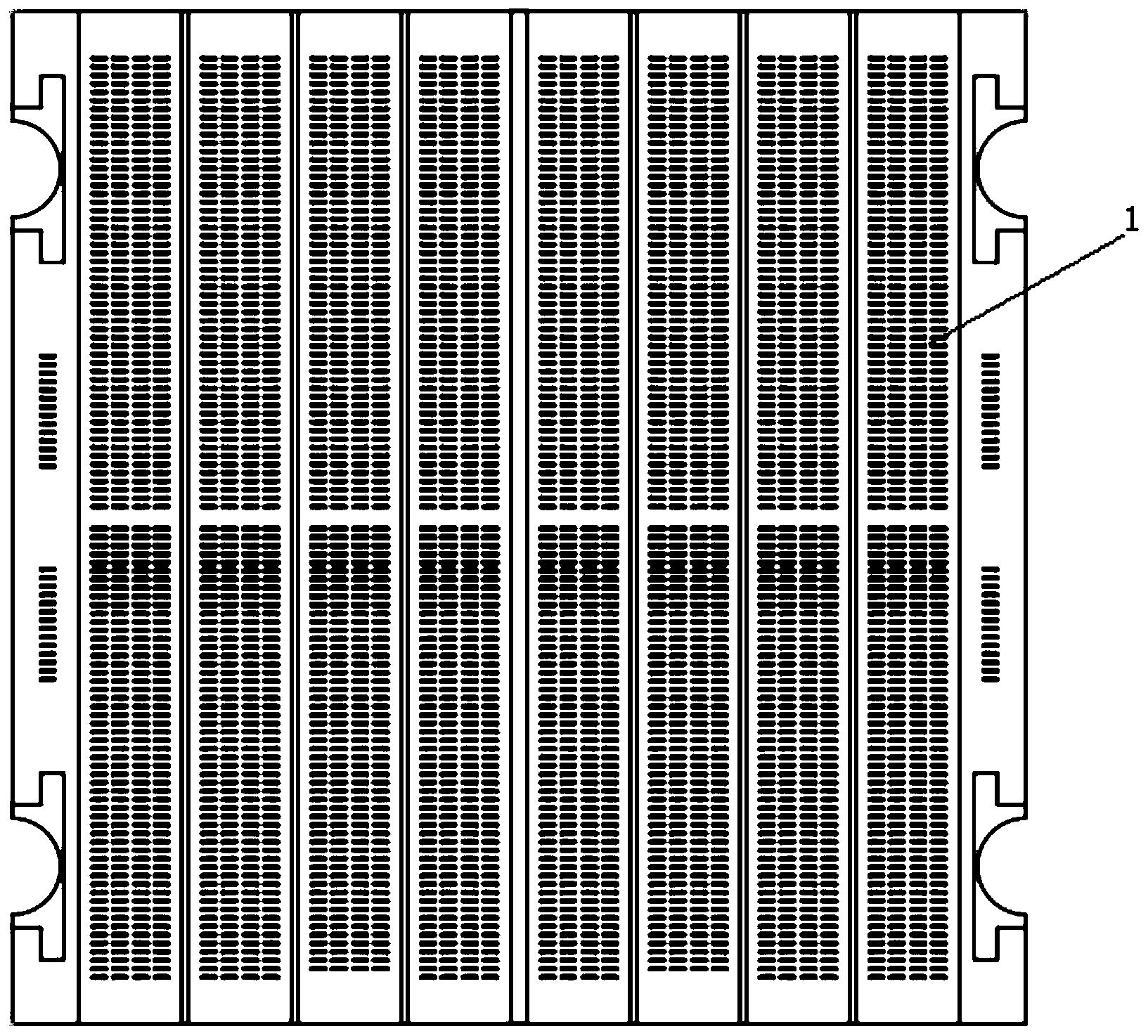

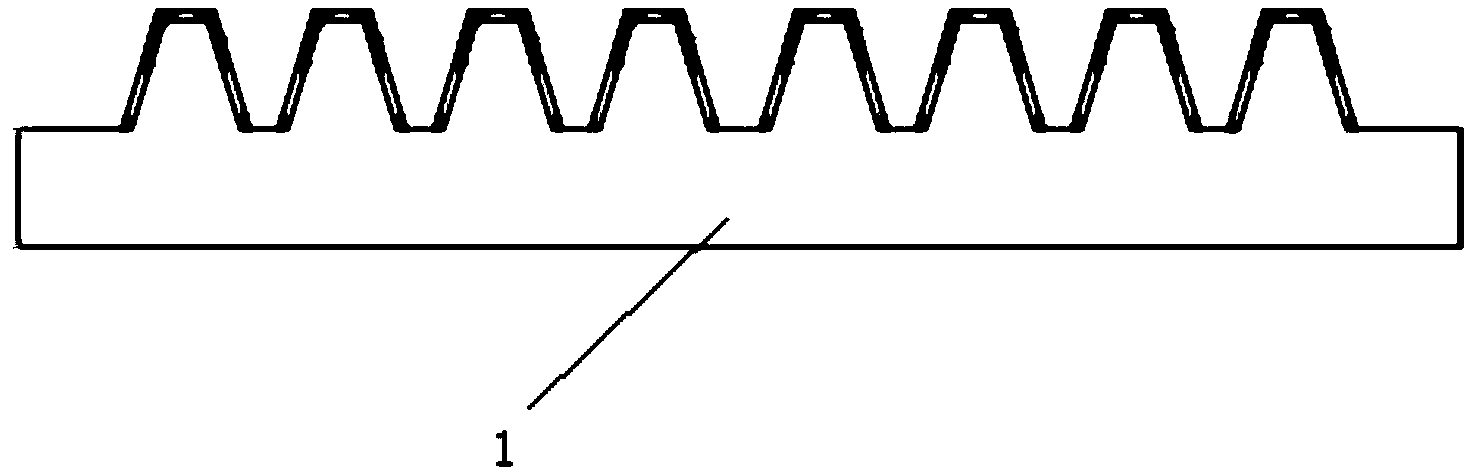

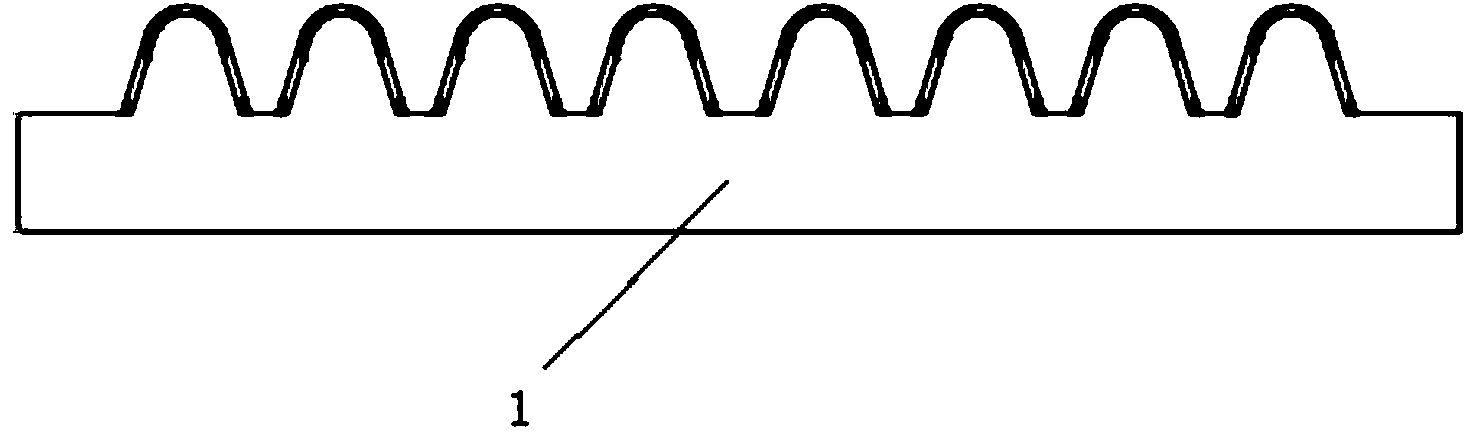

[0016] Referring to the accompanying drawings, a method for forming a non-planar polyurethane screen 1 includes the following steps:

[0017] a. Select high-strength polyurethane material, heat it in an oven to 140°, and carry out dehumidification and dehumidification treatment. After the raw material is dried, it enters the mixer, and at the same time, nano-materials, fumed silica, and ultra-fine toner are added to form synthetic materials. ;

[0018] b. Secondary synthesis with 400-ton injection molding machine, built-in Tian-shaped skeleton, the temperature of the first stage is controlled at 203°, and the method of vacuuming is used to adjust the control of one stage to facilitate molding. The mold temperature of the second stage is controlled at 180°. The temperature of the three stages is 100°C, 185°C, and 180°C respectively; when demoulding, circulating water needs to be injected to keep the mold cavity shaped after the material enters.

[0019] c. After taking out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com