Wholly-weighed storage bin based on plurality of discharging scrapers

A technology of unloading scraper and storage bin, which is applied in the direction of loading/unloading, container, packaging, etc., which can solve the problems of increased production cost, ineffective effect, and warping of unloading scraper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

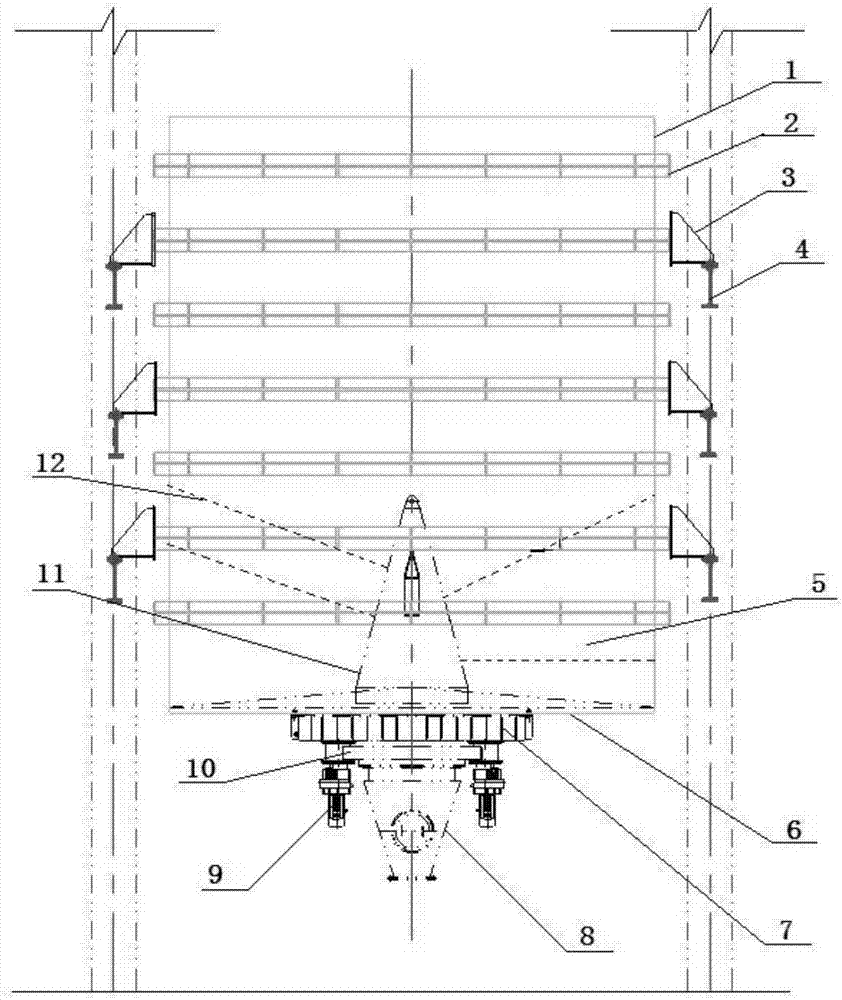

[0027] Such as figure 1 As shown, a kind of integral weighing storage bin based on multiple discharge scrapers described in the embodiment of the present invention includes:

[0028] The storage bin 1 is cylindrical, which is different from the storage bin in which the lower part of the traditional technology is in the shape of an inverted cone or a hyperbolic cone. The silo largely avoids the occurrence of coal blocking.

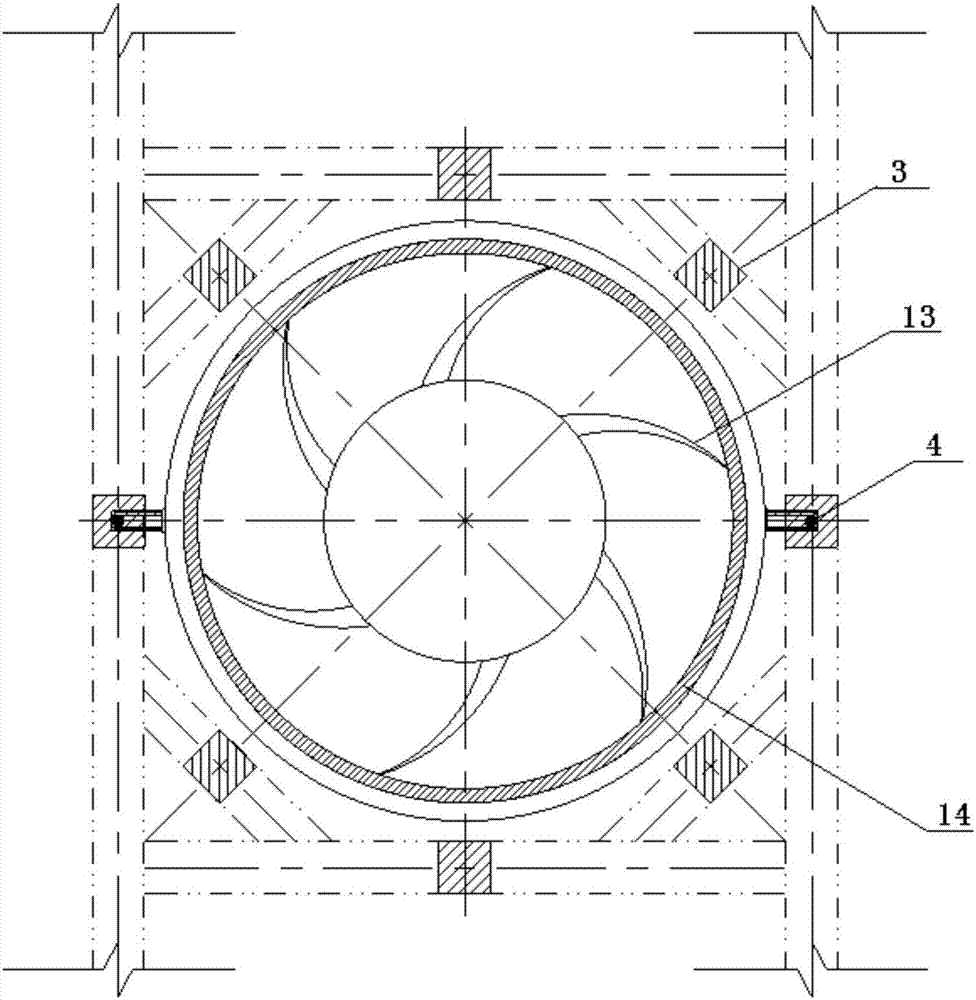

[0029] Reinforcement device 2 is installed on the outside of storage bin 1 to improve the overall stability of raw coal bunker 1, and is evenly distributed at the same interval along the vertical direction of storage bin 1. Reinforcement device 2 is provided with n layers in total. A corbel support 3 is provided on the i-th layer of the device 2, and the reinforcement device 2 is fixed on the corbel suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com