Non-clogging scraper feeder

A non-clogging, feeder technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as hindering the normal operation of the workshop, unable to adjust the amount of coal sent, affecting production efficiency, etc., to achieve uniform force, The effect of preventing coal clogging and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

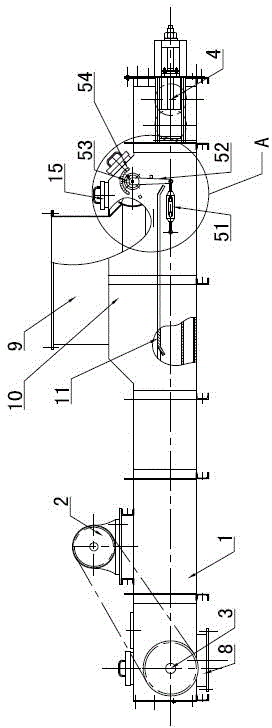

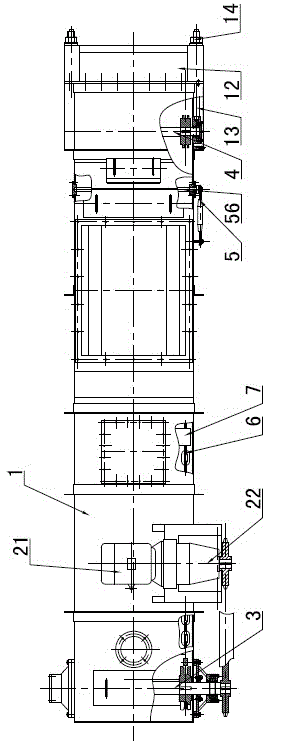

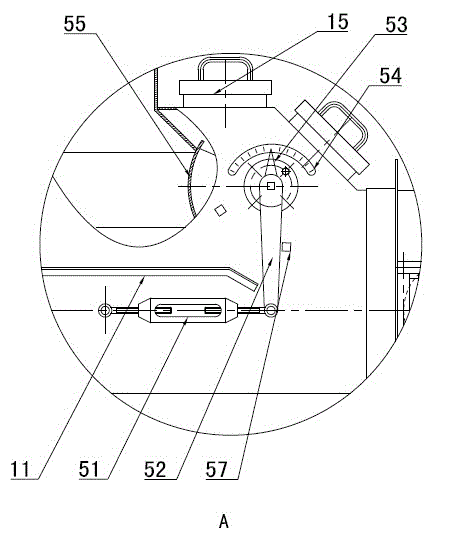

[0023] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0024] Refer to attached Figure 1-3 : Non-clogging scraper feeder, including casing 1, transmission device 2, head shaft assembly 3, tail shaft assembly 4, scraper chain 6 and scraper 7. The casing 1 is placed horizontally and horizontally, and the lower end is supported by side-by-side supporting feet. The casing 1 is made by welding the whole board, and the casing 1 can withstand the pressure of 0.034Mpa. The space between the silo and the feeding port of the feeder is sufficient for material flow, thus avoiding the phenomenon of siloing of fine materials. The upper part of the casing 1 is provided with a plurality of inspection ports 15, the inspection ports 15 are respectively arranged above the head shaft assembly 3 and the tail shaft assembly 4, a cover plate is provided above the inspection port 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com