Rubber product one-step injection, hollowing and vulcanization forming production method

A rubber product, vulcanization molding technology, applied in the field of rubber product technology, can solve the problems of poor dynamic balance effect, poor comfort, uneven tire pressure, etc., to reduce harmful gas emissions, avoid process flow costs, The effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

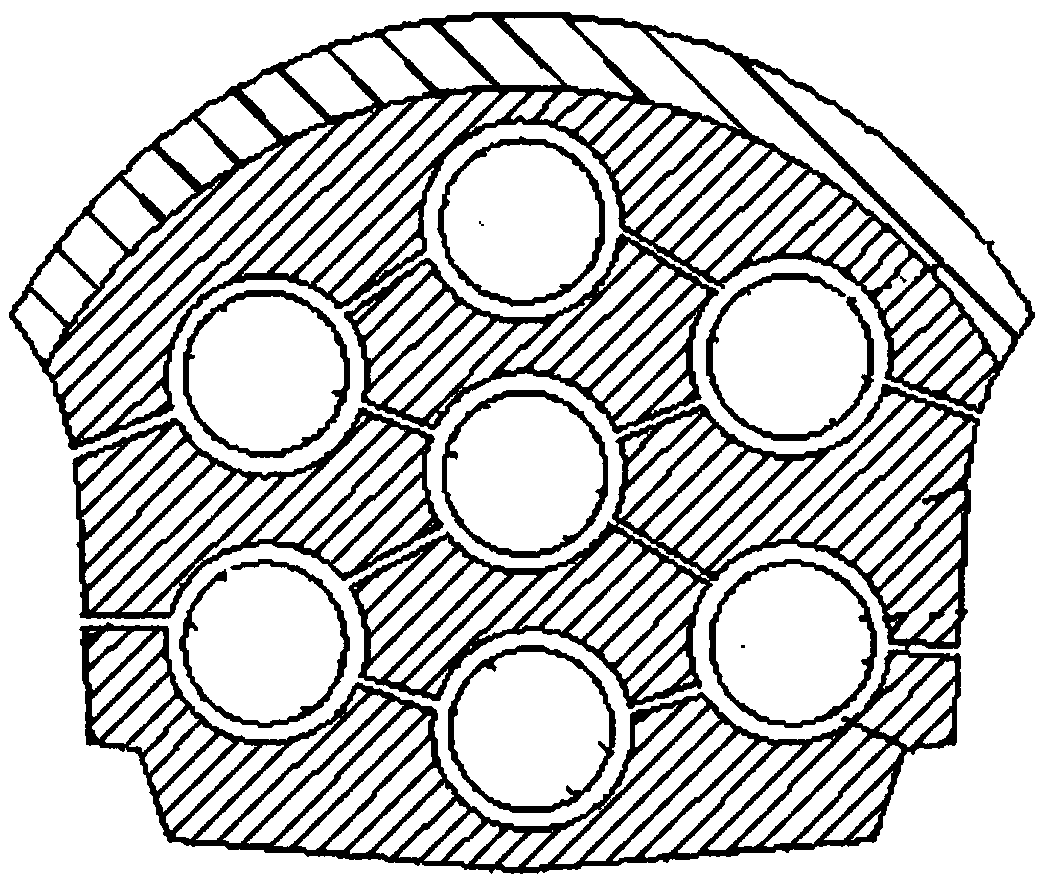

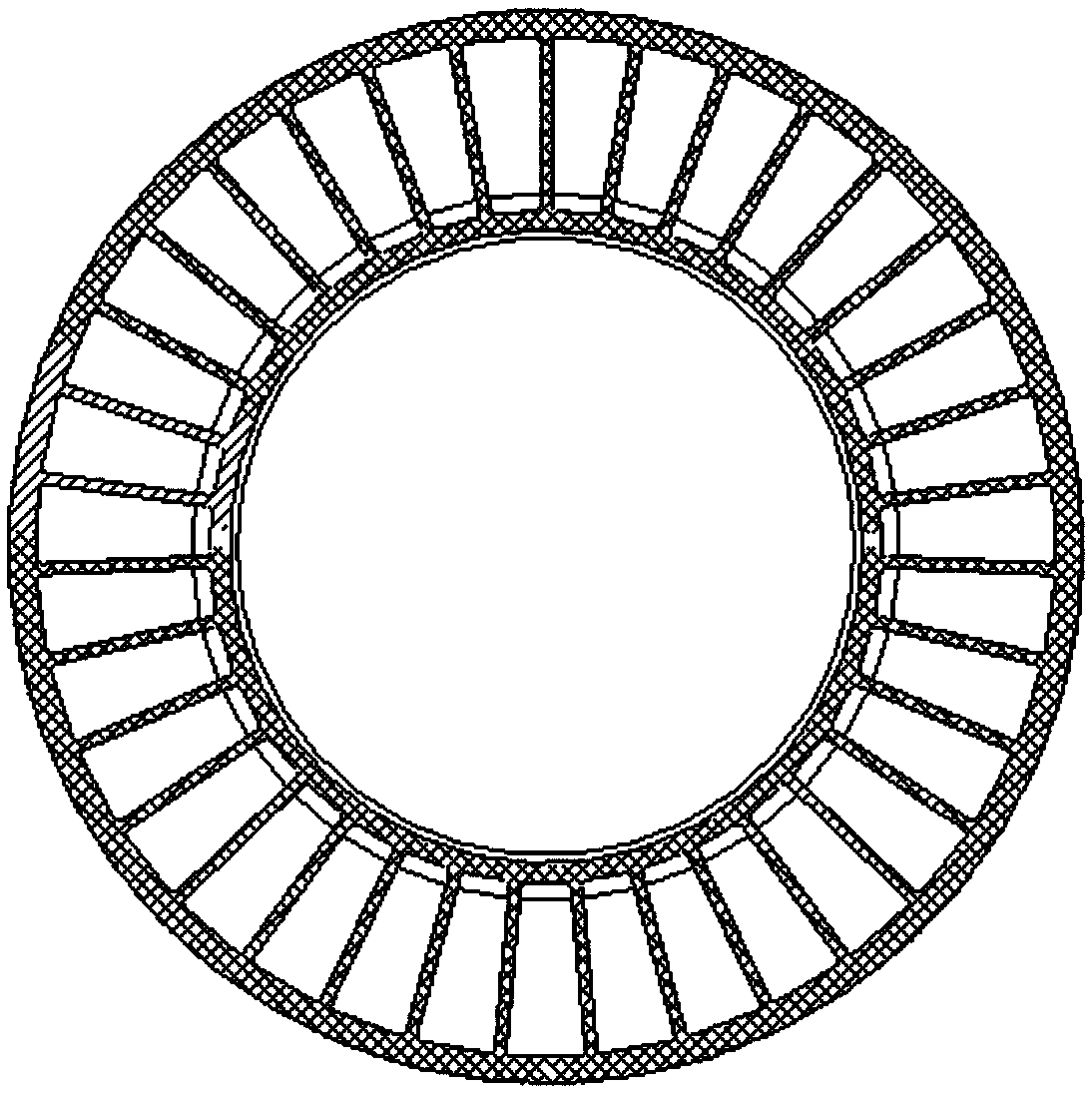

[0043]The one-time injection, hollow and vulcanization production method of rubber products in this embodiment completes the injection, hollow and vulcanization processes in the same mold cavity. The mold cavity includes an upper half mold, a lower half mold and a mold core. The hollow of the cavity lays the foundation. After the hollow, it has the conditions to fill the high-temperature and high-pressure gas required for vulcanization, and then integrates the injection molding, hollow and vulcanization devices, avoiding the heat loss and process flow caused by the flow of various processes in the prior art. It solves the disadvantages of repressurization, heating, energy consumption, time consumption and high cost in the traditional rubber product production process.

Embodiment 2

[0045] The specific steps of the one-time injection, hollow and vulcanization molding production method of rubber products in this embodiment are as follows:

[0046] Step 1. Rubber plasticization: Plasticize the rubber particles in the plasticizing injection screw, and the plasticized fluid rubber is temporarily stored in the plasticizing cavity. Generally, the plasticizing temperature is 60-100°C. The purpose is to Fluidize the rubber material, facilitate the subsequent injection, and keep warm, which can be kept warm by a built-in heater in the ring wall of the plasticizing chamber;

[0047] Step 2. Mold closing: the upper half mold and the lower half mold are closed to form a mold cavity, and the mold core is left at the geometric center of the mold cavity. During the mold closing process, the mold cavity can be heated to 130-180°C. Heaters are added to the outer wall of the half-mold and the lower half-mold to achieve the purpose and ensure the vulcanization requirements ...

Embodiment 3

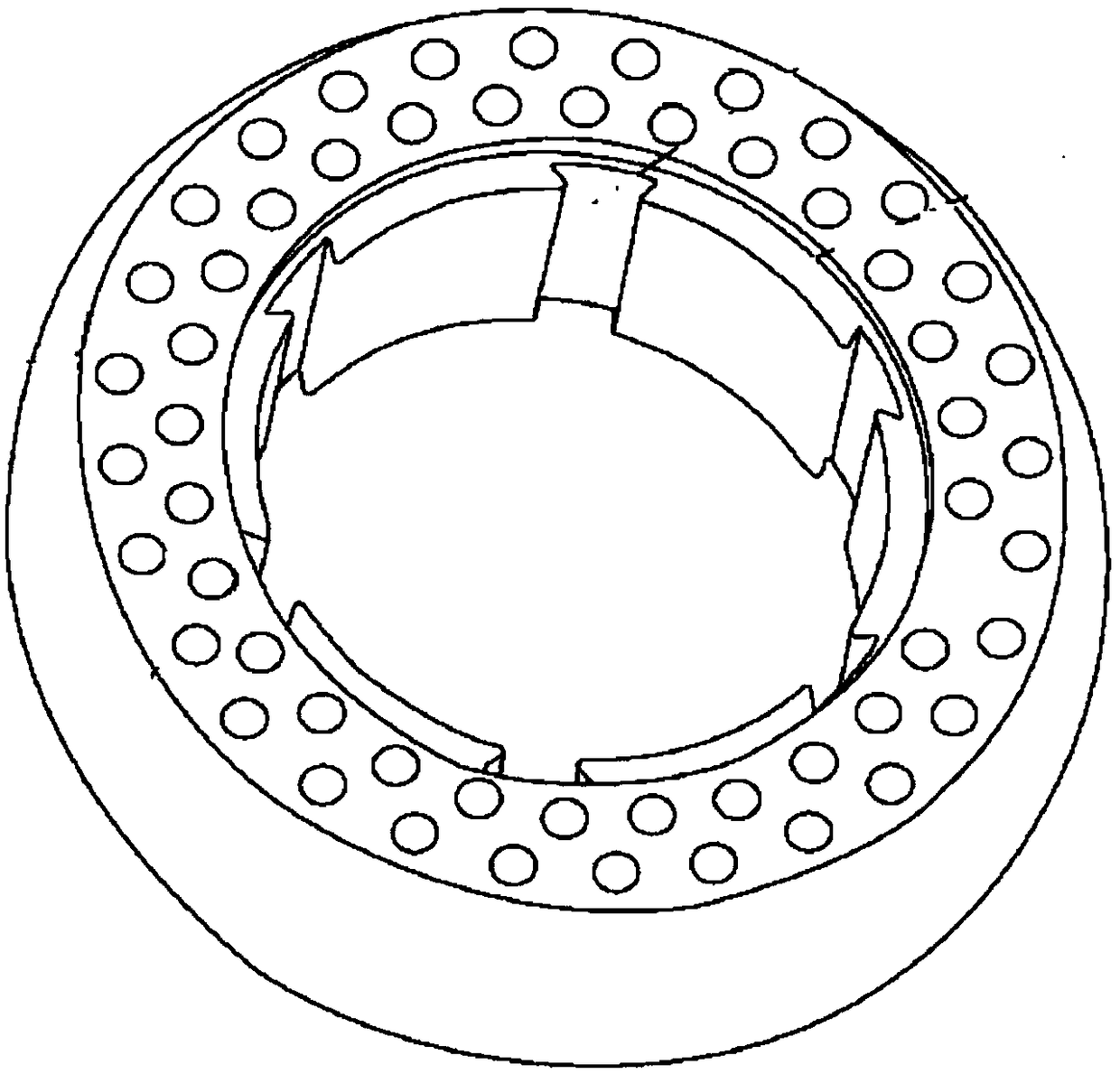

[0056] The production method of disposable injection, hollow and vulcanization molding of rubber products in this embodiment, the basic steps are the same as in Example 2, and the production is as follows: image 3 The inner cavity shown is a fan-shaped compartment tire with a diameter of 200mm. The specific steps are:

[0057] Step 1. Rubber plasticization: the regenerated rubber particles of cross-linkable waste rubber are plasticized in the plasticizing injection screw, and the plasticized fluid rubber is temporarily stored in the plasticizing chamber, and the plasticizing temperature is 60°C , the purpose is to fluidize the rubber material, facilitate the subsequent injection, and keep warm, which can be kept warm by a built-in heater in the ring wall of the plasticizing chamber;

[0058] Step 2, mold closing: the upper half mold and the lower half mold are closed to form a mold cavity. The shapes of the upper half mold and the lower half mold are both in the shape of a ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com