Spray castable single-color double-density rubber tire and molding process thereof

A rubber tire and molding process technology, applied in the field of rubber tires, can solve the problems of complex extrusion process, poor tire comfort, high failure rate, etc., and achieve the effects of reducing energy consumption, uniform dynamic balance, and stable production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

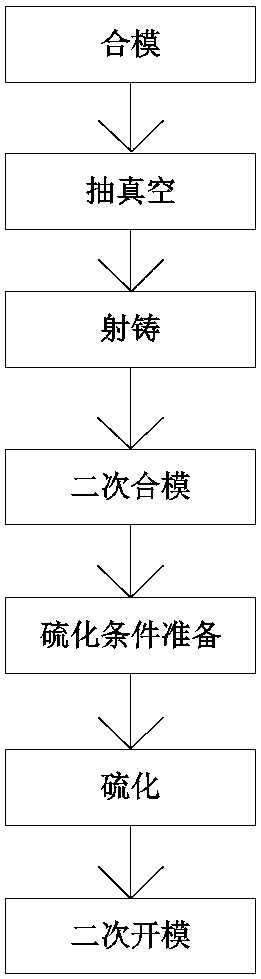

[0037] The injection-castable single-color double-density rubber tire molding process includes the following steps,

[0038] Step 1: Close the mold, close the upper half mold and the lower half mold to form a mold cavity, set the mold core in the mold cavity, the mold cavity is divided into the upper mold cavity and the lower mold cavity with the mold core as the boundary, take the rubber material for double density injection casting;

[0039] Step 2: Open the mold, open the mold cavity, separate the upper half mold and the lower half mold respectively containing half a rubber tire, and automatically remove the mold core;

[0040] Step 3: second mold closing, the upper half mold and the lower half mold respectively containing half of the rubber tire are closed twice, and the inside of the rubber tire is hollow after the mold core is removed;

[0041] Step 4: Put in the preformed lightweight and high-elastic rubber foam tire, and close the mold to make it suitable for vulcaniz...

Embodiment 2

[0045] The injection-castable single-color double-density rubber tire molding process includes the following steps,

[0046] Step 1: Close the mold, close the upper half mold and the lower half mold to form a mold cavity, set the mold core in the mold cavity, the mold cavity is divided into the upper mold cavity and the lower mold cavity with the mold core as the boundary, take the rubber material for double density injection casting;

[0047] Step 2: Open the mold, open the mold cavity, separate the upper half mold and the lower half mold respectively containing half a rubber tire, and automatically remove the mold core;

[0048] Step 3: second mold closing, the upper half mold and the lower half mold respectively containing half of the rubber tire are closed twice, and the inside of the rubber tire is hollow after the mold core is removed;

[0049] Step 4: Put in the preformed lightweight and high-elastic rubber foam tire, and close the mold to make it suitable for vulcanizat...

Embodiment 3

[0056] The injection-castable single-color double-density rubber tire molding process includes the following steps,

[0057] Step 1: Close the mold, close the upper half mold and the lower half mold to form a mold cavity, set the mold core in the mold cavity, the mold cavity is divided into the upper mold cavity and the lower mold cavity with the mold core as the boundary, take the rubber material for double Density injection casting; the upper half mold, lower half mold and mold core match the shape of the rubber tire to be formed, and the mold cavity and injection table are all fixed positions. Heating is carried out by setting heaters on the outer walls of the upper half mold and the lower half mold, so that when the mold is closed, the mold cavity is heated to 130°C~180°C. After closing the mold and before injection casting, vacuumize to make the mold cavity in a negative pressure state. During double-density injection casting, the material temperature is 60°C~80°C, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com