Production method for ultra-low quantitative corrugated core paper and product produced thereby

A technology for corrugated core paper and production method, which is applied in the field of recycled corrugated core paper and corrugated core paper, and can solve the problems of reducing the production of micro-corrugated base paper and low quantification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

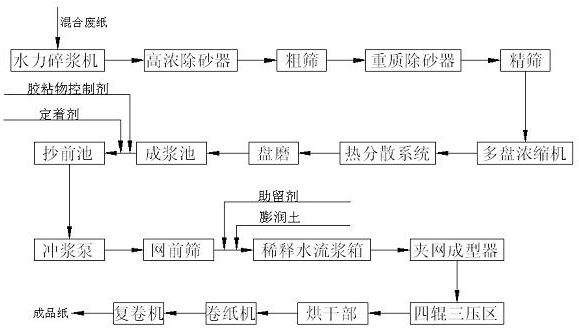

[0014] The specific steps of the production method of ultra-low weight corrugated medium paper of the present invention are described in further detail below:

[0015] 1. Raw material ratio: the present invention uses the mixed waste paper of imported office waste paper and domestic yellow board waste paper as raw materials to produce ultra-low quantitative corrugated medium paper, and the mass percentage of the two is 20-30:80-70, according to the waste paper The quality of paper raw materials and the quality of finished paper require proper adjustment of the ratio.

[0016] 2. Waste paper treatment: Send the mixed waste paper into the hydraulic pulper for disintegration. The sieve plate of the pulper has an aperture of 13-16mm, and the pulp concentration after disintegration is controlled between 3.5-4.0%. ; After crushing, the slurry is sent to the high-concentration desander to remove relatively heavy and large impurities such as sand, ironware, and glass; the slurry from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com