Double-air-chamber box body for transmitting suspended materials

A technology of material transmission and dual air chambers, which is applied in the field of long-distance material transmission systems, can solve problems affecting system operation stability, obvious eddy current phenomenon, air hole blockage, etc., and achieve resource saving, high transportation efficiency, and reduced power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with accompanying drawings.

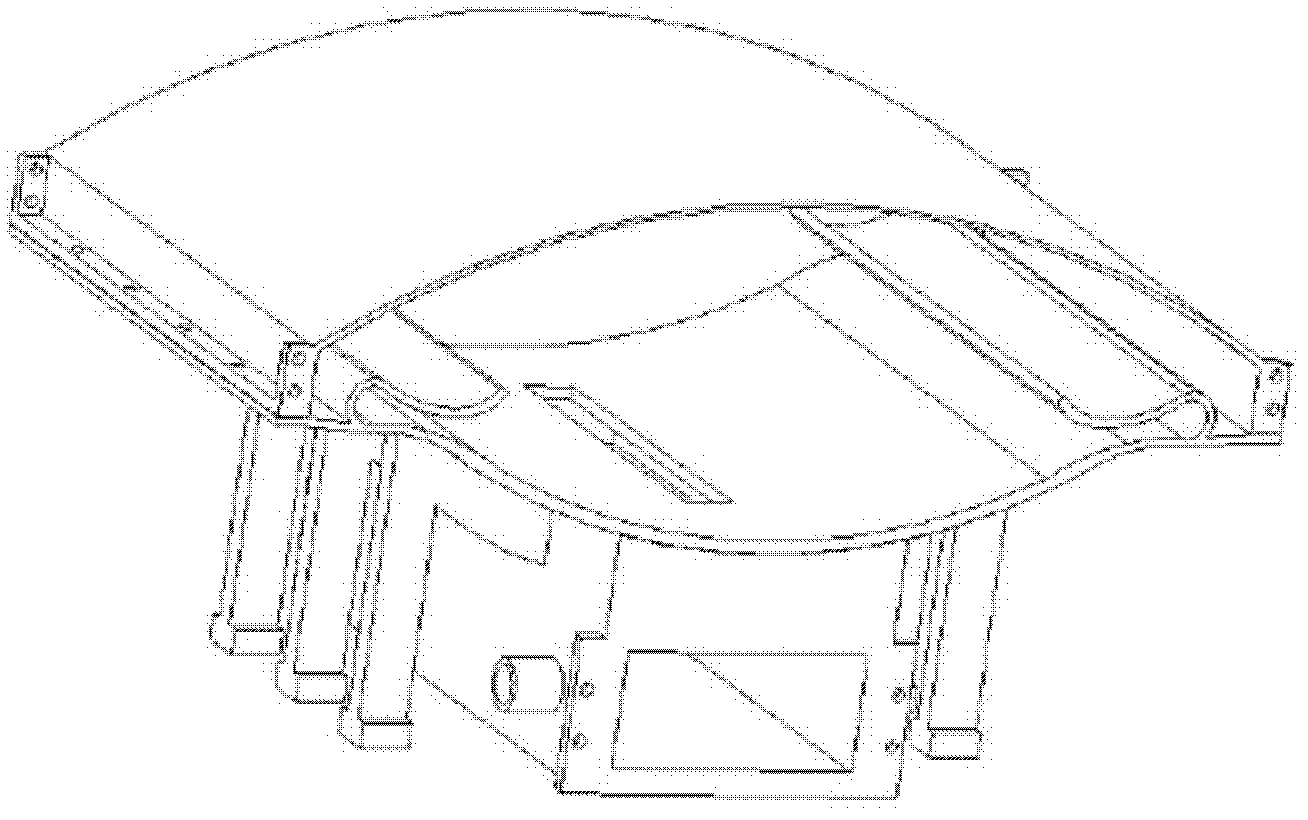

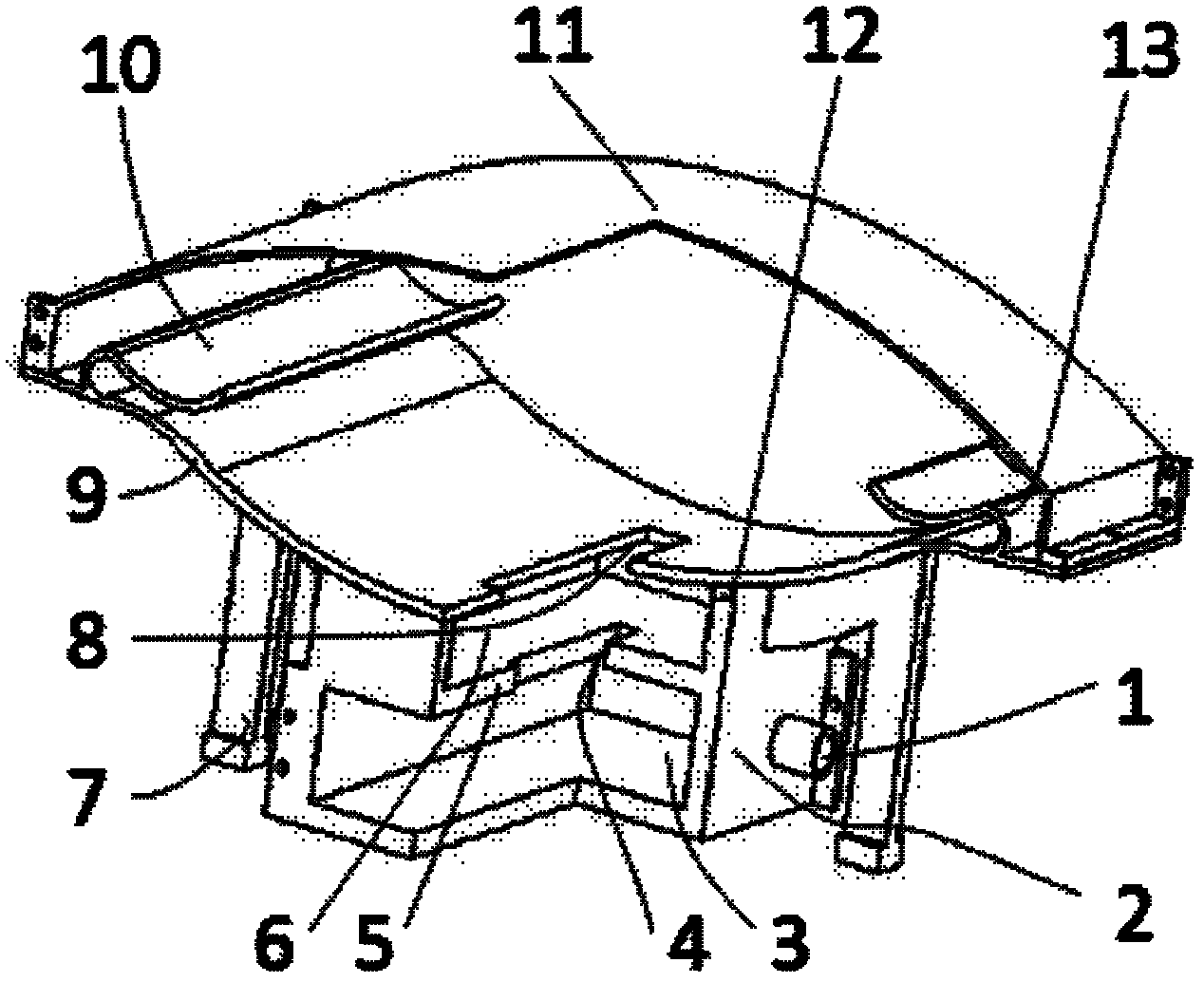

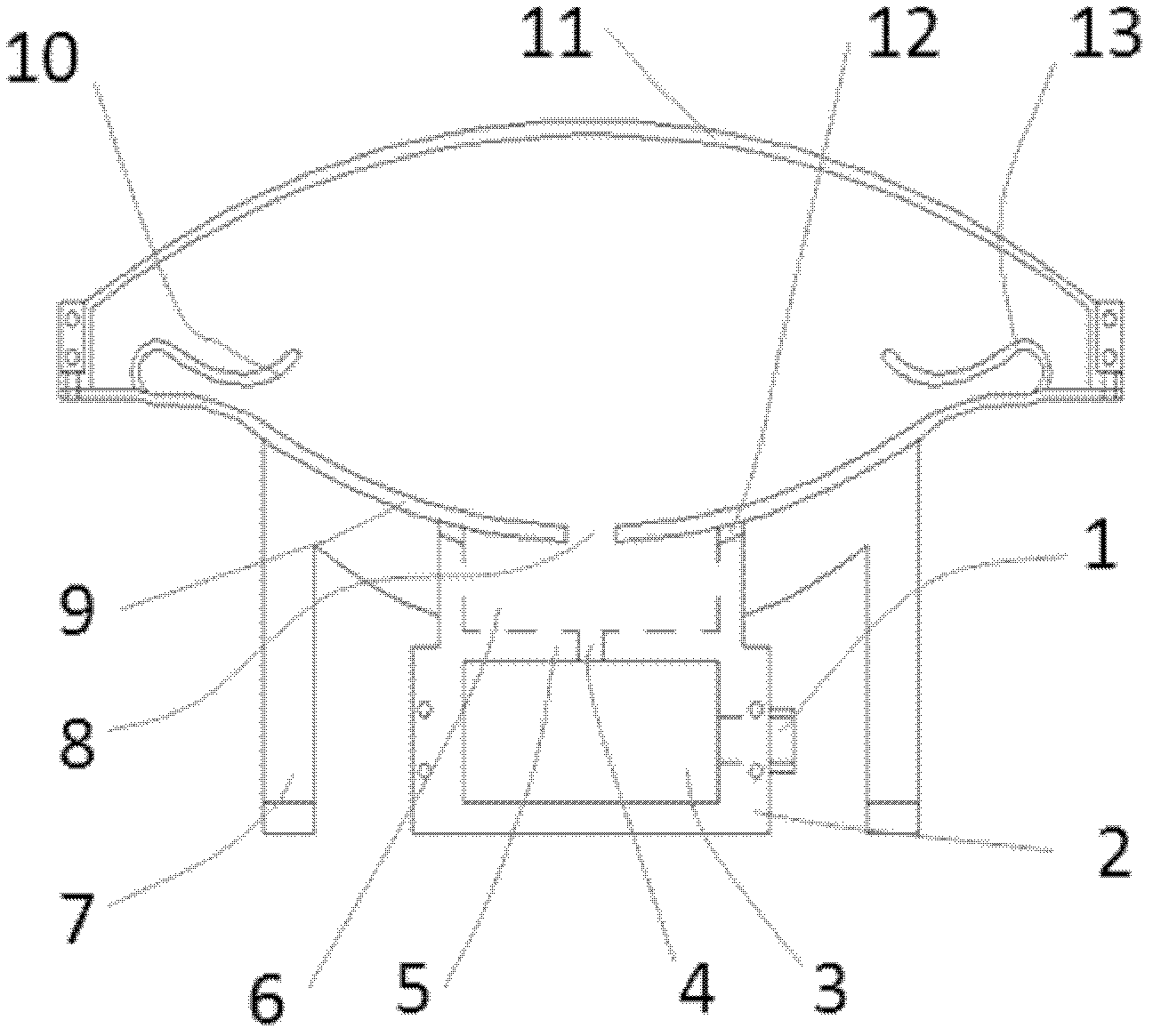

[0028] A double air chamber box for suspended material transfer, such as figure 2 As shown, it includes: an air chamber box 2, an airflow partition 5, a disc groove 9, a first arc body 10, a second arc body 13, a protective cover 11, and a rubber sealing tape 12.

[0029] First and second arc-shaped bodies 10, 13 are welded on both sides of the concave arc surface of the disc groove 9, forming a combination of the disc groove and the arc-shaped body; a disc groove air gap 8 is opened in the middle of the disc groove 9, such as Figure 7 , 8 , as shown in 9.

[0030] Compared with the air hole opening of the disc groove in the traditional material conveying system, the pan groove air slot 8 generates less eddy current and has less impact on the air cushion layer. The width of the slot air slot 8 on the disc slot 9 is twice the diameter of the through hole on the existing disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com