Hollow tire mold core, hollow tire based on mold core and tire manufacturing method

A manufacturing method and hollow technology are applied in the field of hollow tires and tire manufacturing, and hollow tire mold cores, which can solve the problems of poor wear resistance of non-pneumatic tires, not easy to clean, and high manufacturing costs, so as to reduce harmful gas emissions and avoid heat loss. and process flow costs, the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

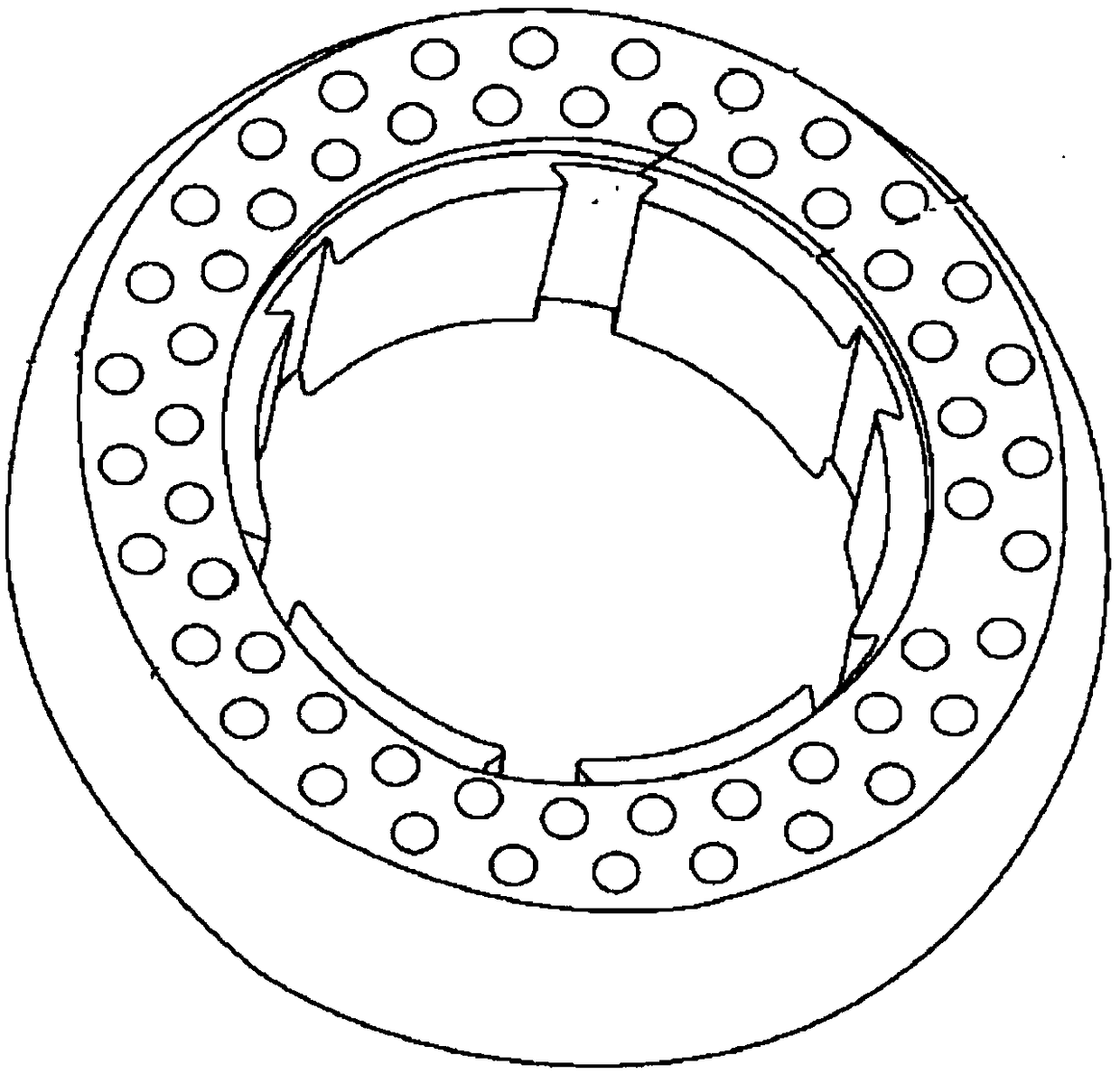

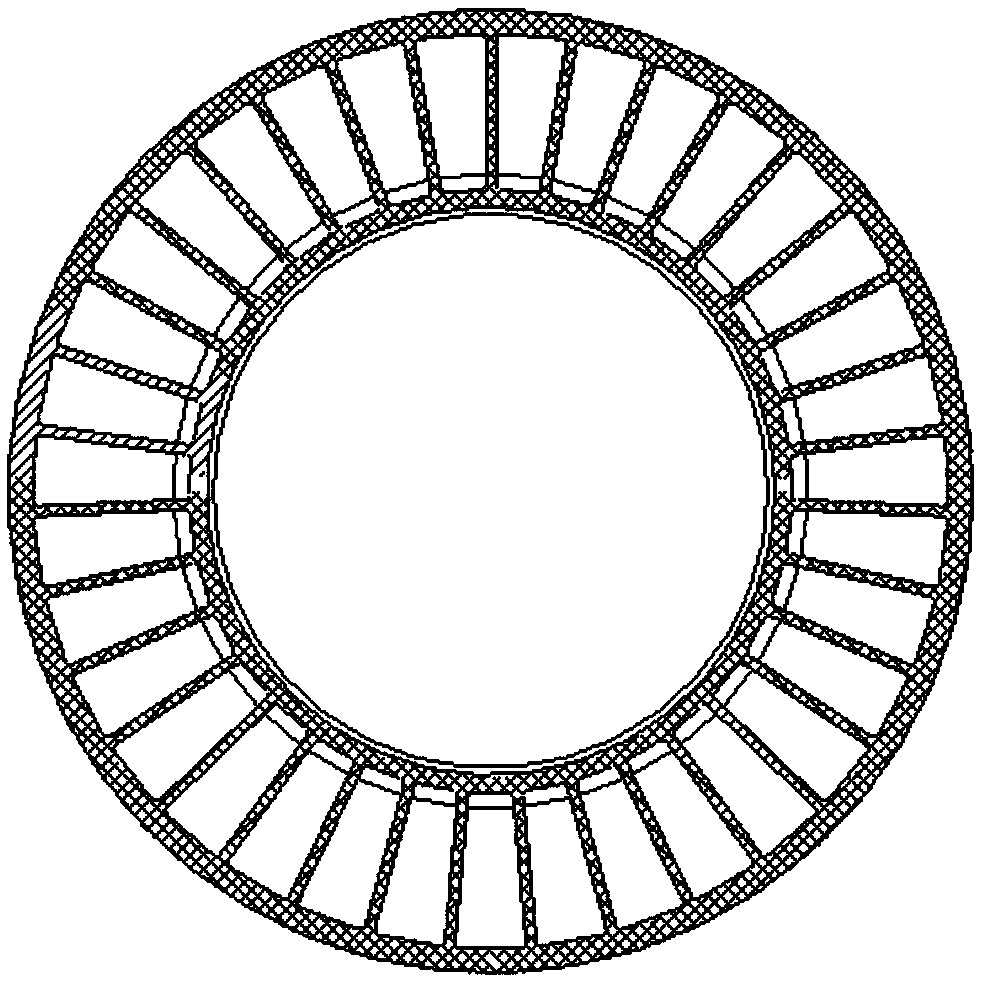

[0059] The hollow tire mold core 2 of this embodiment is applied to Figure 5 As shown in the cavity of the hollow and vulcanization molding device 1, such as Image 6 , 7 , 8, including a square core plate 21 and a circular upper core 22 and a lower core 23 arranged symmetrically on the upper and lower ends of the core plate 21; the upper core 22 and the lower core 23 The combined shape and size are as Picture 9 The cavity 33 of the hollow tire 3 shown is uniform.

[0060] The hollow tire 3 of this embodiment based on the above hollow tire core 2 is such as Picture 9 , 10 The shown includes a circular carcass 31 and a hollow inner cavity 33; the inner cavity 33 is provided with a tire frame 32 along the circular direction; the tire frame 32 can be in the shape of a wine barrel, a wheat ear, a propeller or a cross The grid shape, etc., in this embodiment is a series-connected wine barrel arch shape, which is consistent with the series-connected wine barrel arch shape of the comb...

Embodiment 2

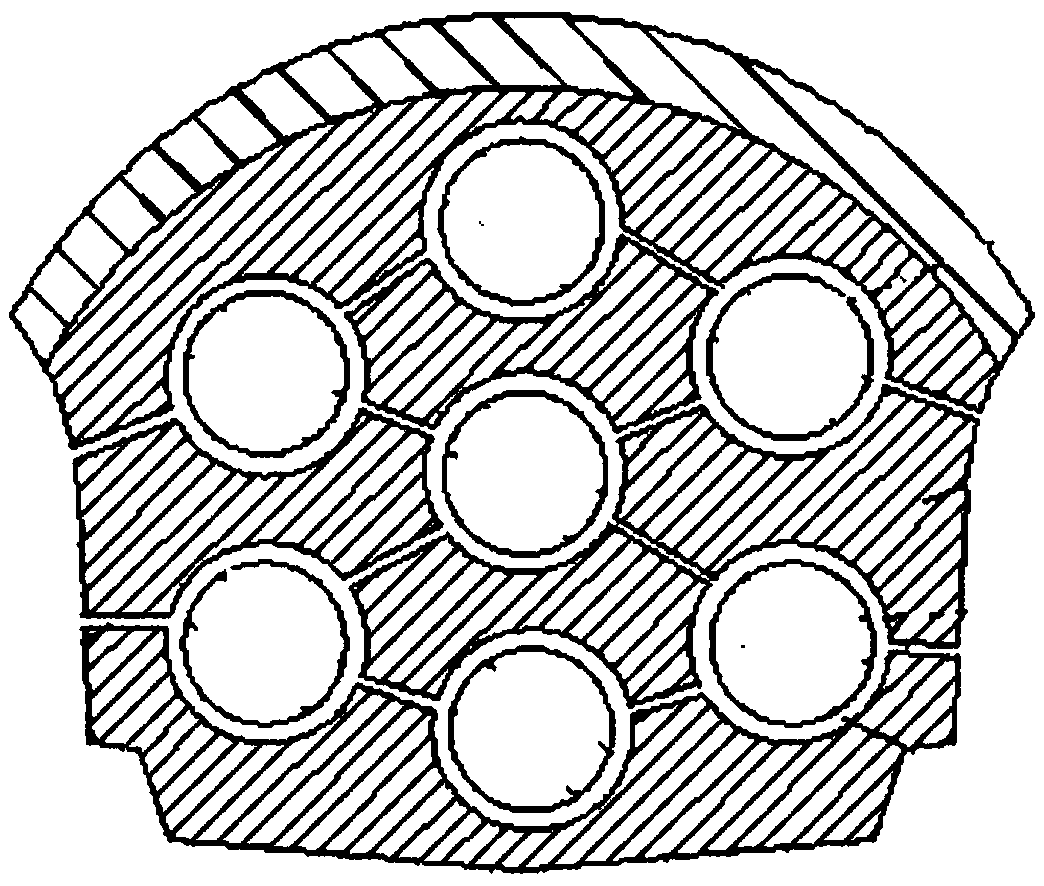

[0063] The basic structure of the hollow tire mold core 2 of this embodiment is the same as that of the embodiment 1. The difference and improvement are as follows: Figure 7 As shown, the mold core plate 21 in the upper mold core 22 and the lower mold core 23 protrudes outwardly to form a mold core ring protrusion 24 forming a gas channel 33 in the hollow tire 3;

[0064] The hollow tire 3 of the present embodiment based on the above hollow tire mold core 2 has an annular convex mold core 24. An annular gas channel 34 can be reserved at the annular center of the hollow tire 3. If the hollow tire 3 needs to be inflated, pass through the gas channel 34 communicates with the inner cavity 33 of the hollow tire 3.

[0065] The manufacturing method of the hollow tire 3 of this embodiment, the specific steps are:

[0066] Step 1. Rubber plasticization: The rubber particles are plasticized in the plasticizing injection screw, and the plasticized fluid rubber is temporarily stored in the pla...

Embodiment 3

[0076] The basic structure of the hollow tire core 2 and the core-based hollow tire 3 of this embodiment is the same as that of the second embodiment. The difference and improvement lies in that the upper end surface edge of the core plate 21 of the hollow tire core 2 is provided with positioning grooves. , It can facilitate the positioning of the upper mold half, the lower mold half and the hollow tire mold core 2 when they are closed.

[0077] The hollow tire 3 and tire manufacturing method of this embodiment, the basic steps are the same as that of embodiment 2, the production is as Picture 9 The inner cavity shown is a barrel-shaped tyre with a diameter of 200mm in series, and the specific steps are:

[0078] Step 1. Rubber plasticization: plasticize recycled rubber particles of crosslinkable waste rubber in a plasticizing injection screw. The plasticized fluid rubber is temporarily stored in the plasticizing cavity, and the plasticizing temperature is 60°C. , The purpose is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com