Power transmission device with combined pericycloid mechanism and double-crank mechanisms

A double-crank mechanism and power transmission technology, which is applied in the direction of machines/engines, mechanical equipment, combustion engines, etc., can solve the problems of complex shape, difficult implementation, and difficult processing, etc., and achieve a small number of parts, simple structure, and design The effect of many parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

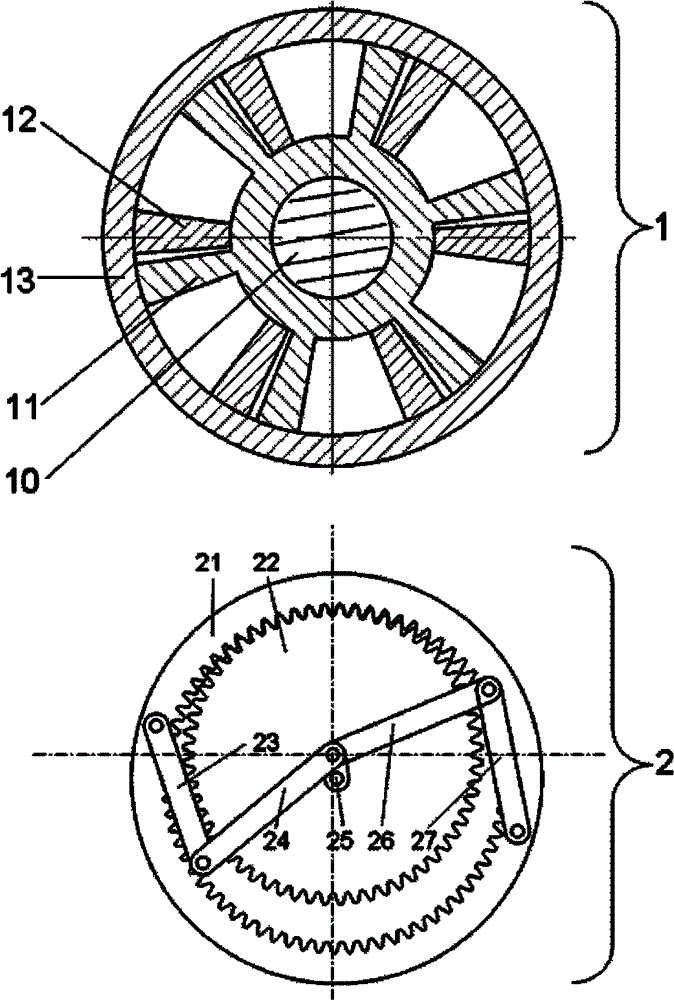

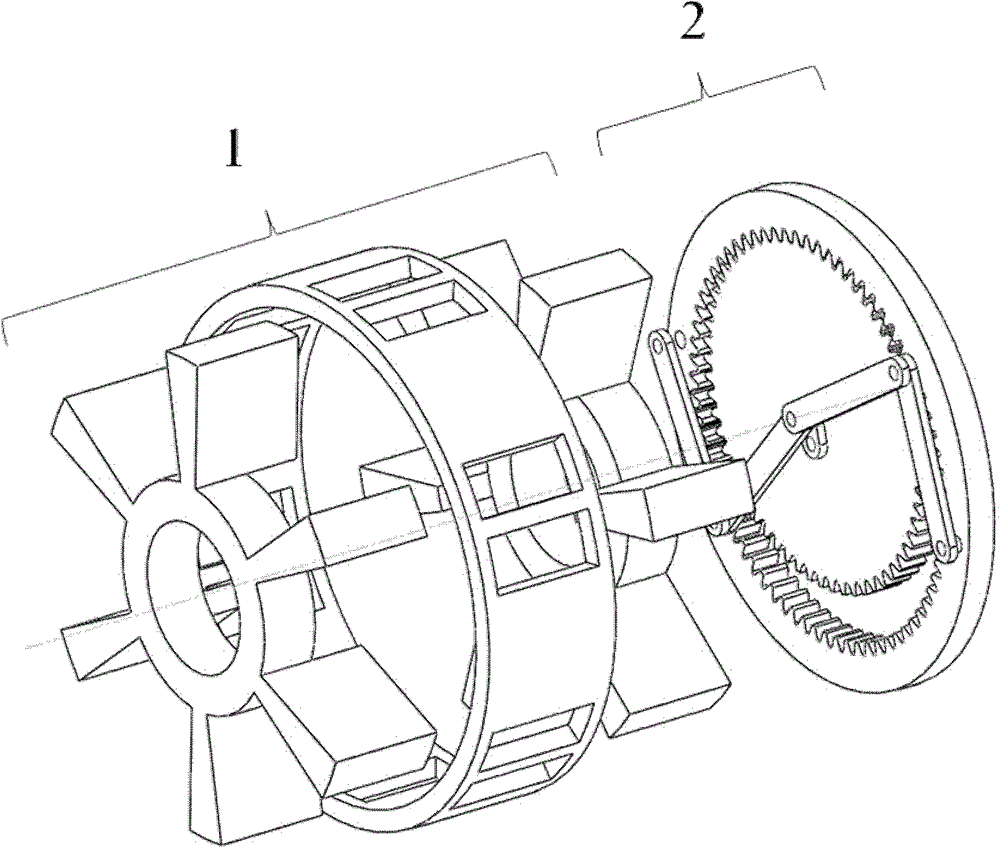

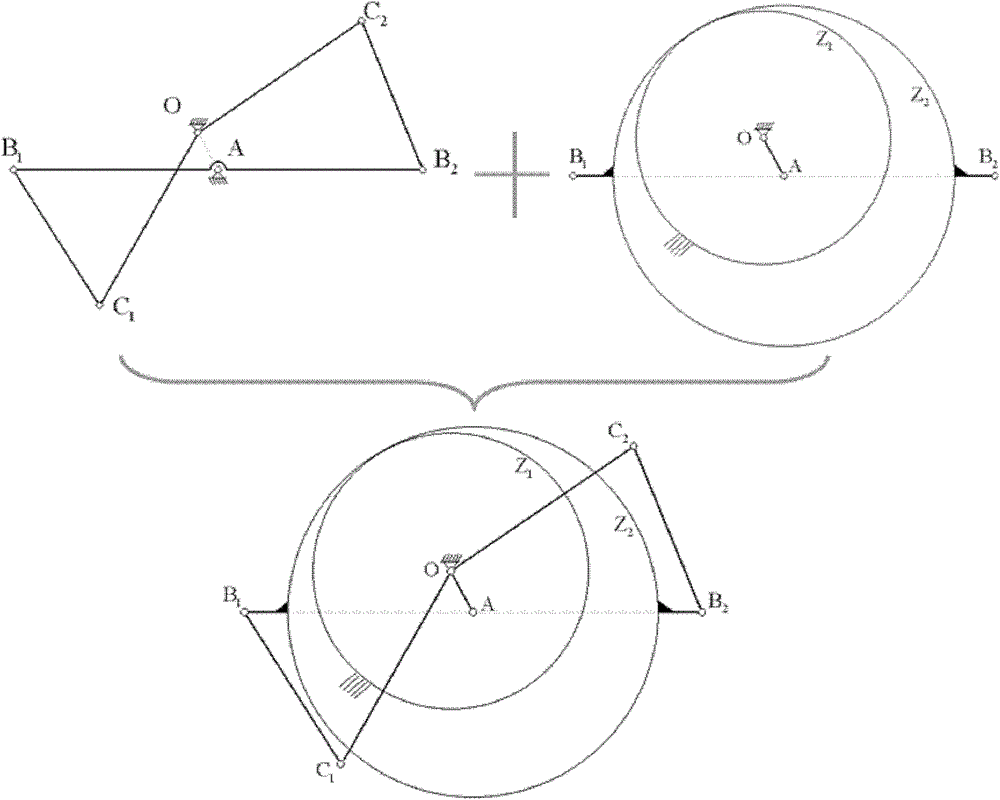

[0023] like figure 1 , figure 2 and image 3 As shown, the power transmission device combined with the cycloid mechanism and the double crank mechanism of the present invention includes a power cylinder assembly 1 and a differential drive assembly 2 connected with the power cylinder assembly 1. The power cylinder assembly 1 includes a rotor I11, a rotor II12, a power cylinder The shaft 10 , the cylinder 13 , the rotor I11 and the rotor II12 are coaxially and staggered (cross-shaped) installed in the cylinder 13 and rotate around the rotation axis of the power shaft 10 . That is, the power cylinder assembly 1 and the differential drive assembly 2 are coaxially arranged and assembled in combination through the respective cylinder blocks. In the power cylinder assembly 1, there are two rotors coaxially installed in the cylinder block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com