Centrifugal molding mold of concrete rectangular pile

A technology of centrifugal forming and rectangular piles, which is applied in the direction of the mold, can solve the problems affecting the quality of the centrifugal forming of concrete square piles, the tube wall of the mold is easily deformed, and the strength is not satisfactory, so as to achieve a simple and reasonable structure and increase the rigidity And the effect of stability and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

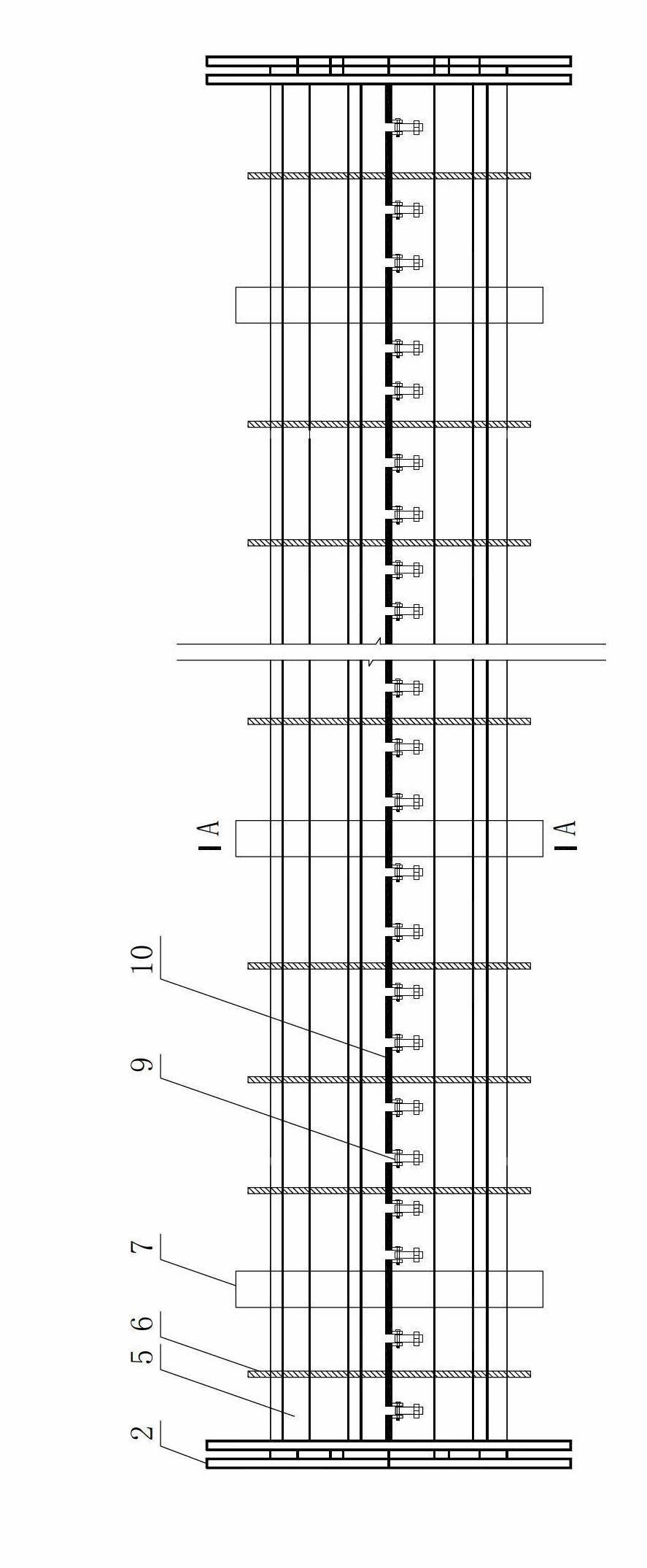

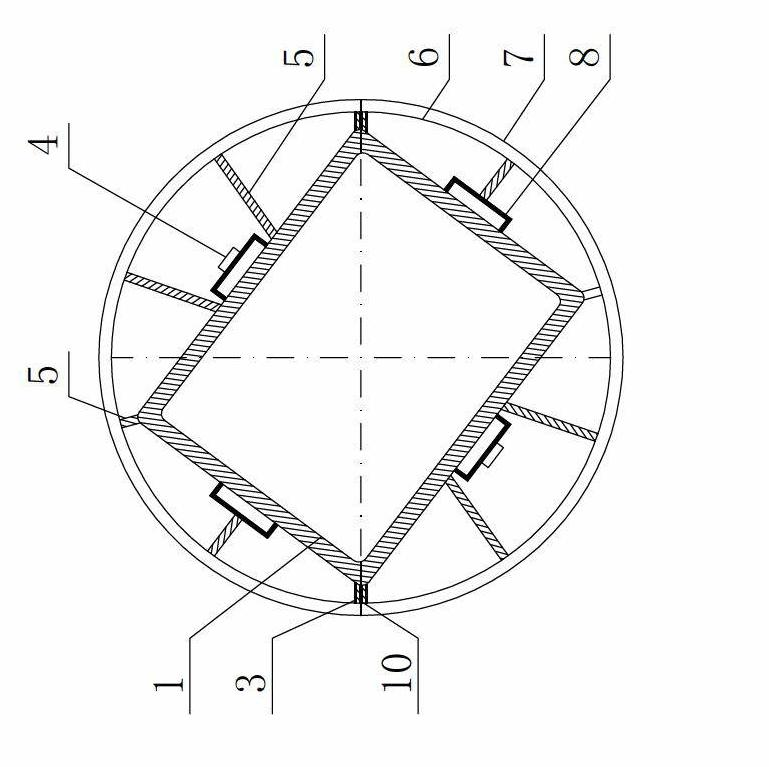

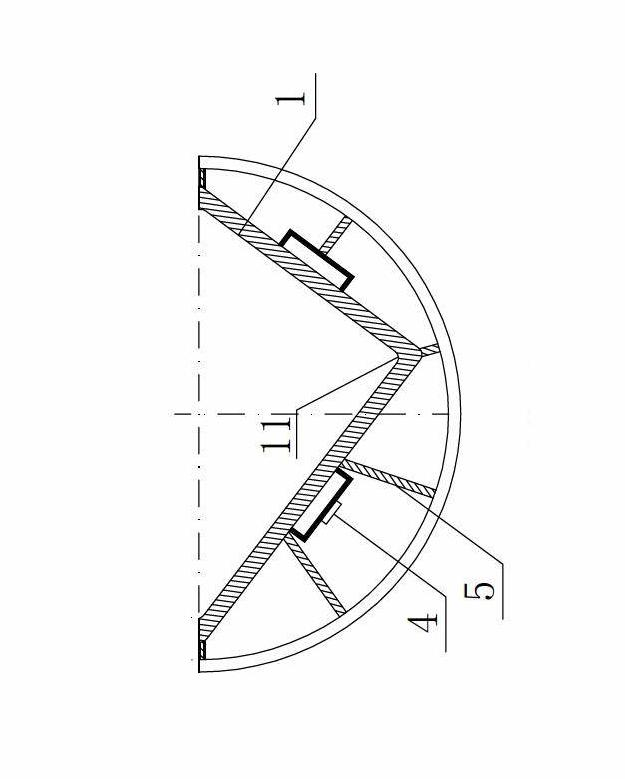

[0020] Embodiment 1, the concrete rectangular pile centrifugal molding mold of the present invention, by two pieces of shapes, butt buckle and connected cross-section is not isosceles right-angled triangle or grows longer than 1.5 times of wide rectangular slot mold 1 and is connected to the mold End plates 2 at both axial ends, tongue and groove plates 3 fixedly connected to both sides of the axial notch of each groove mold 1, centrifugal balancer 4, and reinforcing longitudinal plates 5 fixedly connected to the outside of each groove mold 1 and reinforcing ring plate 6, running wheels 7 of multiple semicircular steel structures fixedly connected to the outside of each groove mold 1, box girder 8 of 冂 shape, clamping bolts 9 for clamping the mold, on the upper and lower Groove mold 1 closing place, sealing pad 10 in the sealing groove of upper or lower groove mold 1 closing place, circular arc interior angle 11 with four sides equal corners, arc radius 4-35mm. The two grooves...

Embodiment 2

[0021] Embodiment 2: concrete rectangular pile centrifugal forming die of the present invention, by two pieces of shape identical, buckle and the cross-section that connects is not isosceles right angle triangle or grows longer than the groove 1 of the rectangle of 1.5 times of width and is connected in mold axial two The end plate 2 at the end, the tongue and groove plate 3 fixedly connected to both sides of the radial notch of each groove, the centrifugal balancer 4, the reinforced vertical plate 5 and the reinforced ring plate 6 fixedly connected to the outside of each groove, fixedly connected to A plurality of semicircular steel structure running wheels 7 on the outside of each groove, a 冂-shaped box girder 8, clamping bolts 9 for mold clamping, at the place where the upper and lower molds are closed, in the sealing groove of the upper mold or the lower mold The sealing ring 10 and the circular arc 11 with equal corners on four sides have a radius of 4-35 mm. The two groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com