Rotary flow pulsation generating device

A flow pulsation and generation device technology, applied in mechanical equipment, circuit components, etc., can solve the problems of large flow pulsation, large axial force, dense arrangement of through holes, etc. in the pipeline system, and achieve excellent dynamic balance characteristics. The effect of small force and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

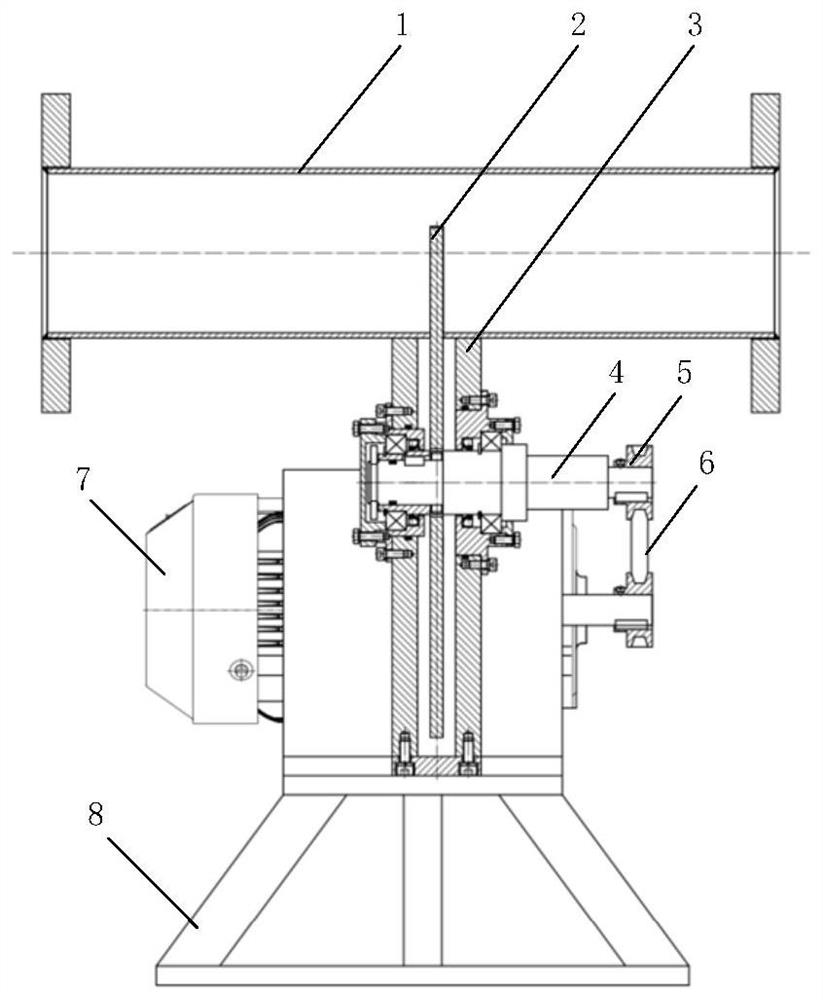

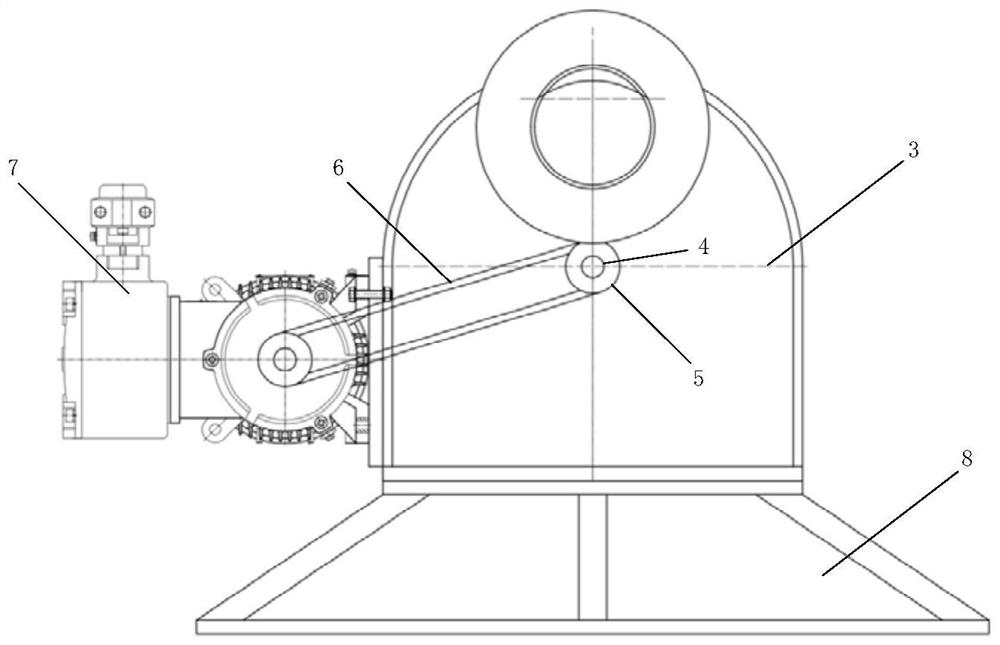

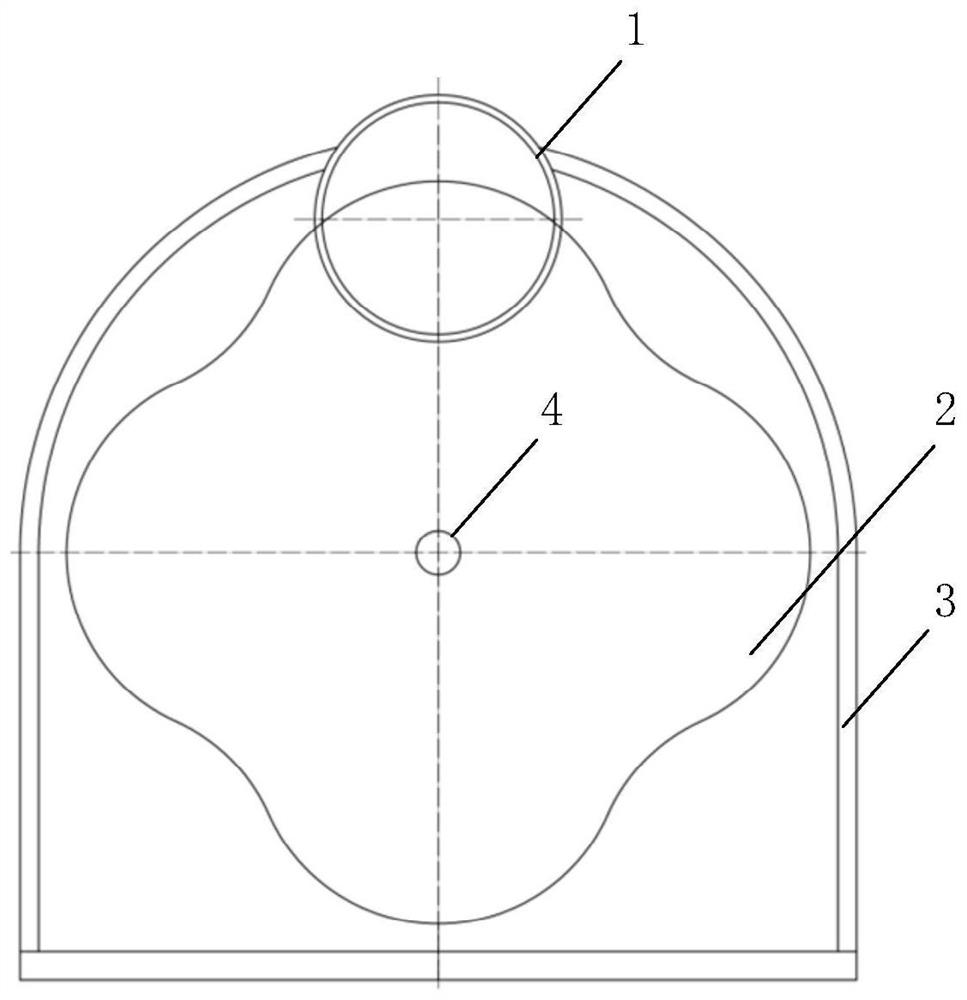

[0017] combine Figure 1-5 , The present invention provides a rotary flow pulsation excitation device with adjustable frequency and amplitude, which includes a pipe section 1, an overcurrent baffle 2, a casing 3, a shaft 4, a pulley 5, a belt 6, a motor 7 and a base 8. The overflow baffle 2 is inserted horizontally into the pipe section 1, and the drive shaft 4 is connected to the overflow baffle 2 by pins. The housing 3 installed outside the overflow baffle 2 acts as a seal, and the drive shaft 4 and the motor 7 pass through the belt 6 Connect with the pulley 5 to ensure that the motor 7 and the drive shaft 4 rotate at the same speed. The whole set of devices is fixed on the base 8, and the base 8 is connected with the ground through anchor bolts. When the motor 7 rotates with the drive shaft 4 and the overflow baffle 2, the flow area of the pipe section 1 cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com