Built-in conical surface pre-positioned permanent magnet synchronous coupler

A permanent magnet synchronous and coupling technology, applied in the field of mechanical transmission, can solve the problems of large size and weight of positioning taper sleeve, easy to generate operation risks, etc., to achieve the effect of optimizing installation work, reducing the workload of on-site debugging, and reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

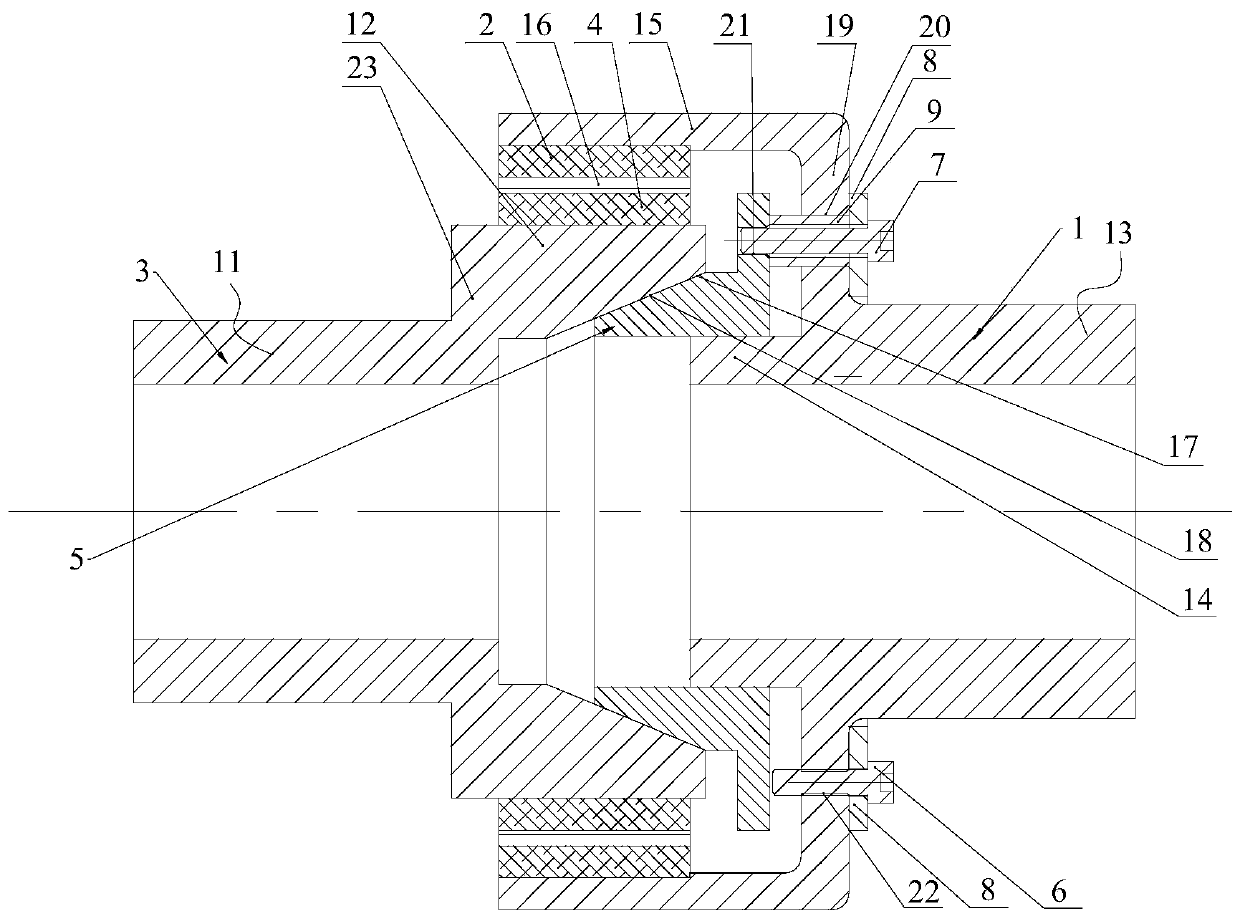

[0065] Such as figure 1 with 2 As shown, a permanent magnet synchronous coupling with built-in conical surface pre-positioning includes two rotors with coincident axes, namely the inner rotor 3 and the outer rotor 1, the inner rotor 3 includes a first body 11, and the first body 11 One end of the outer rotor 1 includes a second body 13, and one end of the second body 13 includes a second annular portion 14 and a third annular portion 15 arranged coaxially, and the third annular portion 15 Located outside the second annular portion 14, and the end surface of the second annular portion 14 is located inside the third annular portion 15, the third annular portion 15 is sheathed on the first annular portion 12, and the third annular portion An outer permanent magnet 2 is installed on the inner side wall of 15, and an inner permanent magnet 4 is installed on the outer side wall of the first annular portion 12, and the outer permanent magnet 2 corresponds to the inner permanent magn...

Embodiment 2

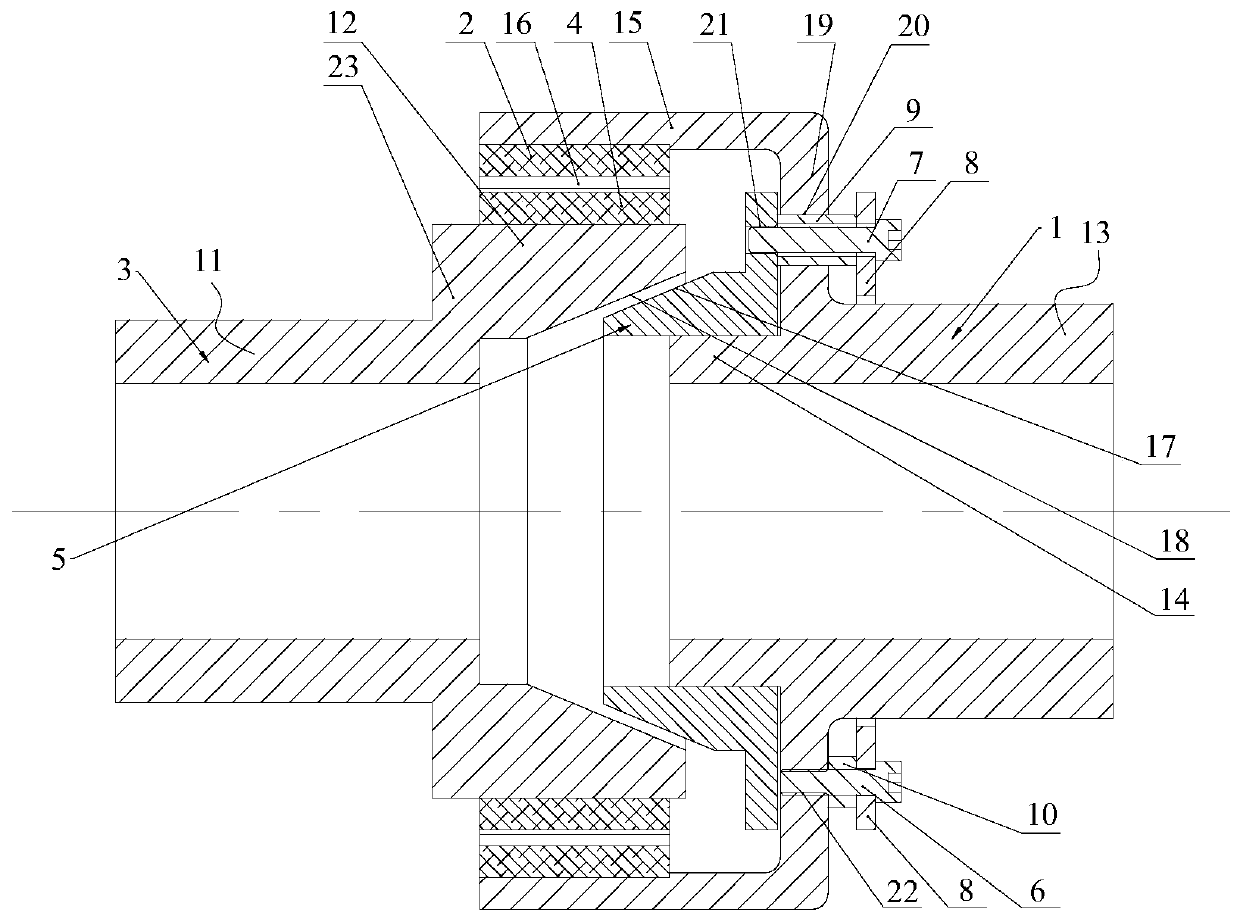

[0083] Such as image 3 with 4 As shown, a permanent magnet synchronous coupling with built-in conical surface pre-positioning includes two rotors with coincident axes, namely the inner rotor 3 and the outer rotor 1, the inner rotor 3 includes a first body 11, and the first body 11 One end of the outer rotor 1 includes a second body 13, and one end of the second body 13 includes a second annular portion 14 and a third annular portion 15 arranged coaxially, and the third annular portion 15 Located outside the second annular portion 14, and the end surface of the second annular portion 14 is located inside the third annular portion 15, the third annular portion 15 is sheathed on the first annular portion 12, and the third annular portion An outer permanent magnet 2 is installed on the inner side wall of 15, and an inner permanent magnet 4 is installed on the outer side wall of the first annular portion 12, and the outer permanent magnet 2 corresponds to the inner permanent magn...

Embodiment 3

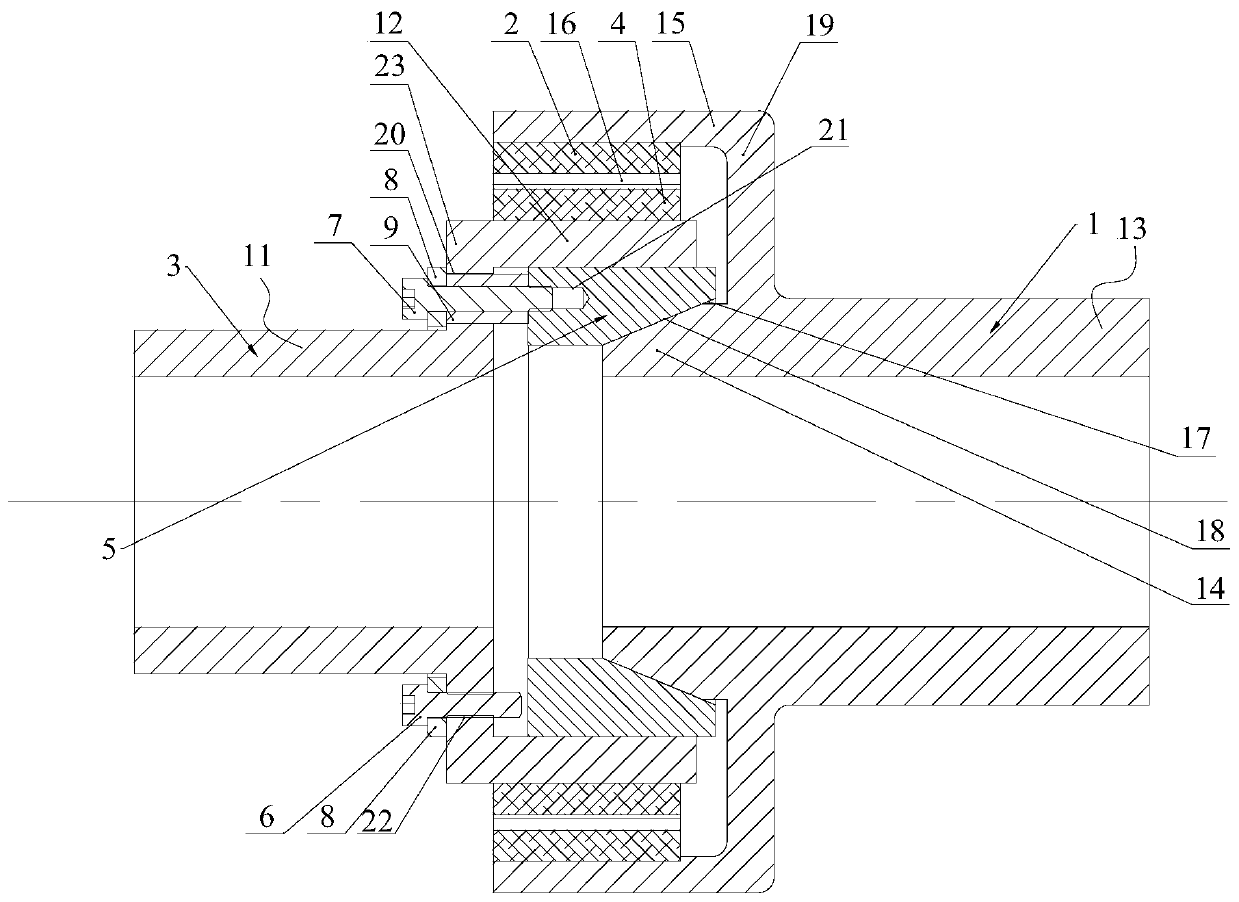

[0097] Such as Figure 5 with 6 As shown, a permanent magnet synchronous coupling with built-in conical surface pre-positioning includes two rotors with coincident axes, namely the inner rotor 3 and the outer rotor 1, the inner rotor 3 includes a first body 11, and the first body 11 One end of the outer rotor 1 includes a second body 13, and one end of the second body 13 includes a second annular portion 14 and a third annular portion 15 arranged coaxially, and the third annular portion 15 Located outside the second annular portion 14, and the end surface of the second annular portion 14 is located inside the third annular portion 15, the third annular portion 15 is sheathed on the first annular portion 12, and the third annular portion An outer permanent magnet 2 is installed on the inner side wall of 15, and an inner permanent magnet 4 is installed on the outer side wall of the first annular portion 12, and the outer permanent magnet 2 corresponds to the inner permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com