Highly-elastic hollow molded rubber tire and making process thereof

A technology of rubber tires and high elasticity, applied in the field of rubber tire products, can solve the problems of low production efficiency, easy air leakage, and high labor intensity of workers, so as to achieve the effects of enhancing elasticity, eliminating transportation costs and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

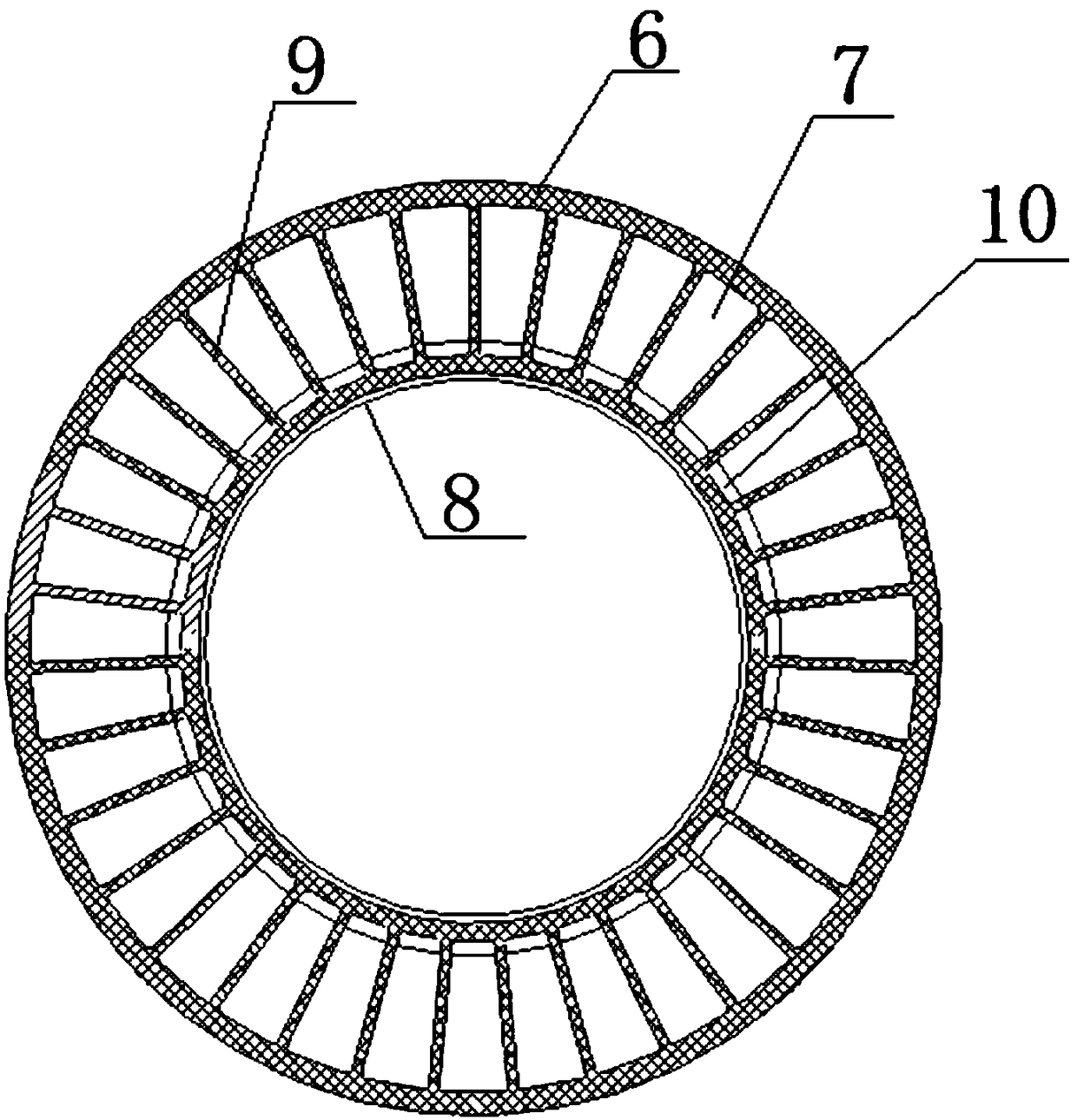

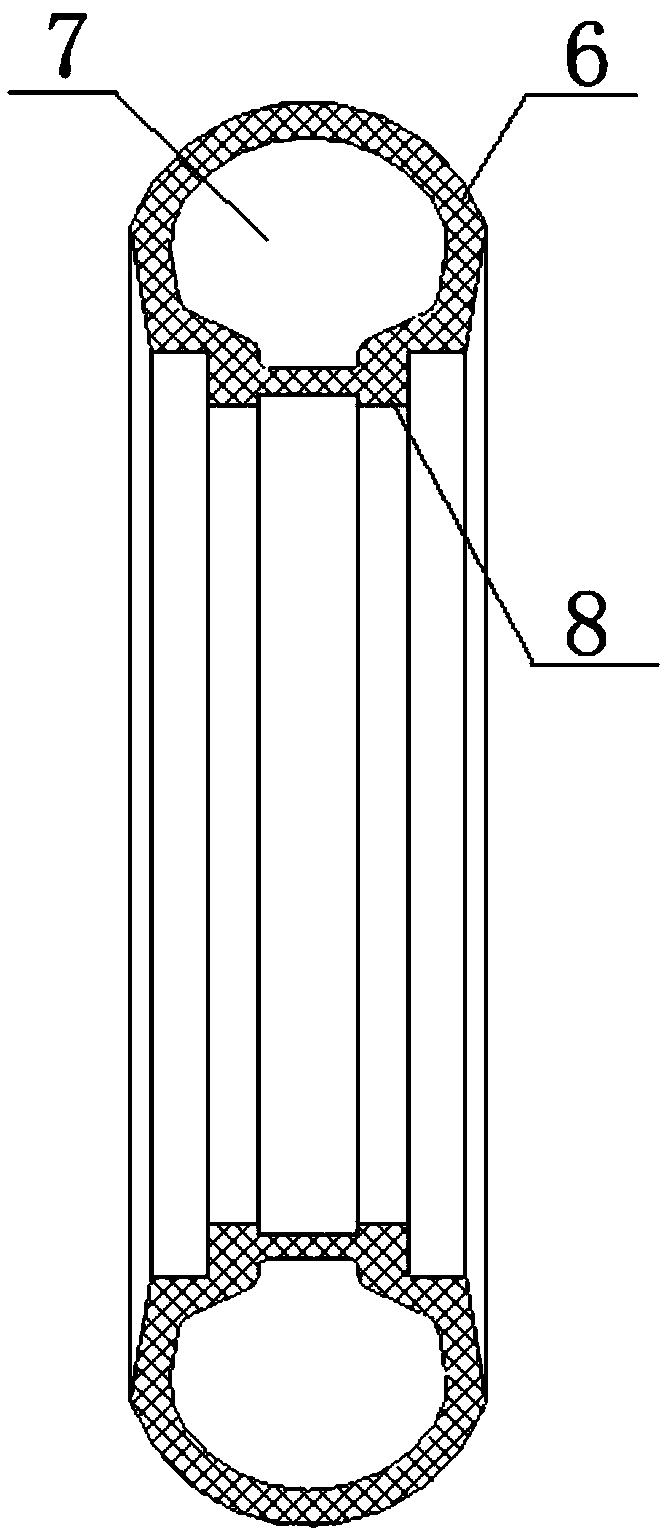

[0056] The high elastic hollow molded rubber tire of the present embodiment, as figure 1 , 2 As shown, it includes a tire body 6, the interior of the tire body 6 is a hollow-molded sealed cavity, and the sealed cavity is evenly separated into a plurality of tire sub-cavities 7 by a partition 9, without additional inflation, when a certain When the cavity is pierced, it does not affect the use of the tire; the inner ring of the tire body 6 is a tire clip 8 that fits the wheel hub, and the shape of the tire clip 8 fits the shape of the wheel hub, and is in a continuous concave-convex step shape. In order to stick to the wheel hub stably.

Embodiment 2

[0058] The high elastic hollow molded rubber tire of the present embodiment, as figure 1 , 2 As shown, the basic structure is the same as in Embodiment 1, and the improvement is that: the inner side of the tire sub-cavity 7 close to the hub is also covered with a tire inner layer 10, and the tire sub-cavity 7 is isolated from the outside world for a second time; the tire body The outer layer of 6 is provided with a steel wire braided layer and a nylon wire braided layer to meet the requirements of wear resistance and high strength; the tire card edge 8 is covered with a high-strength thick steel wire layer to ensure the fit between the tire and the wheel hub. The separator 9 and the tire body 6 are an integrated structure of the same material that is released from the same mold, and can be integrally injection molded; the separator 9 can be designed to be thin enough, smaller than the tire thickness, and enhance its elasticity; the material of the tire inner layer 10 It is a ...

Embodiment 3

[0060] The basic structure of the high-elastic hollow-molded rubber tire of this embodiment is the same as that of Embodiment 1, and the improvement is that: the outer layer of the tire body 6 is provided with a steel wire braided layer and a nylon wire braided layer to meet the requirements of wear resistance and high strength; the tire The card edge 8 is covered with a high-strength thick steel wire layer to ensure the fit between the tire and the wheel hub. The partition 9 and the tire body 6 are an integrated structure of the same material that is released from the same mold, and can be integrally injection molded; the partition 9 can be designed to be thin enough, less than the tire thickness, to enhance its elasticity.

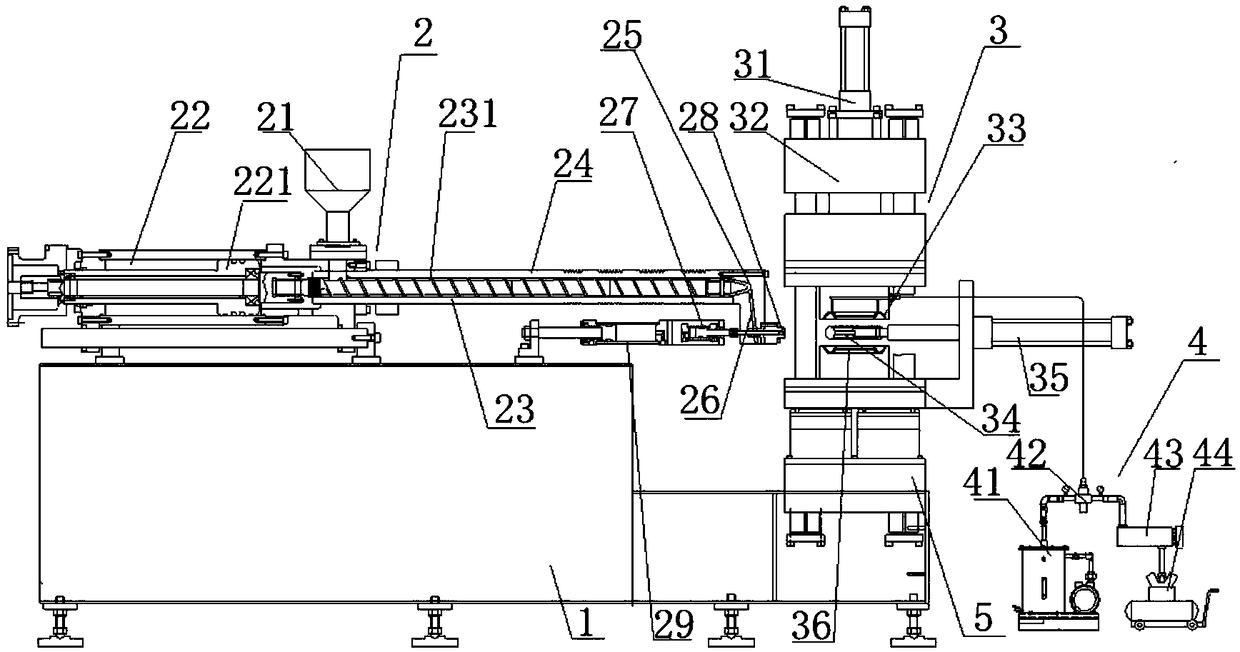

[0061] The high-elastic hollow-molded rubber tire of this embodiment is produced by one-step injection, hollowing, and vulcanization processes of a one-time molding production system, and the injection, hollowing, and vulcanization of the high-elastic hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com