Adaptive order tracking vibration reduction metamaterial shaft structure

A technology of order tracking and metamaterials, applied in the direction of rotation vibration suppression, vibration suppression adjustment, spring/shock absorber, etc., can solve problems such as inability to change, achieve good vibration and noise reduction effects, good dynamic balance, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

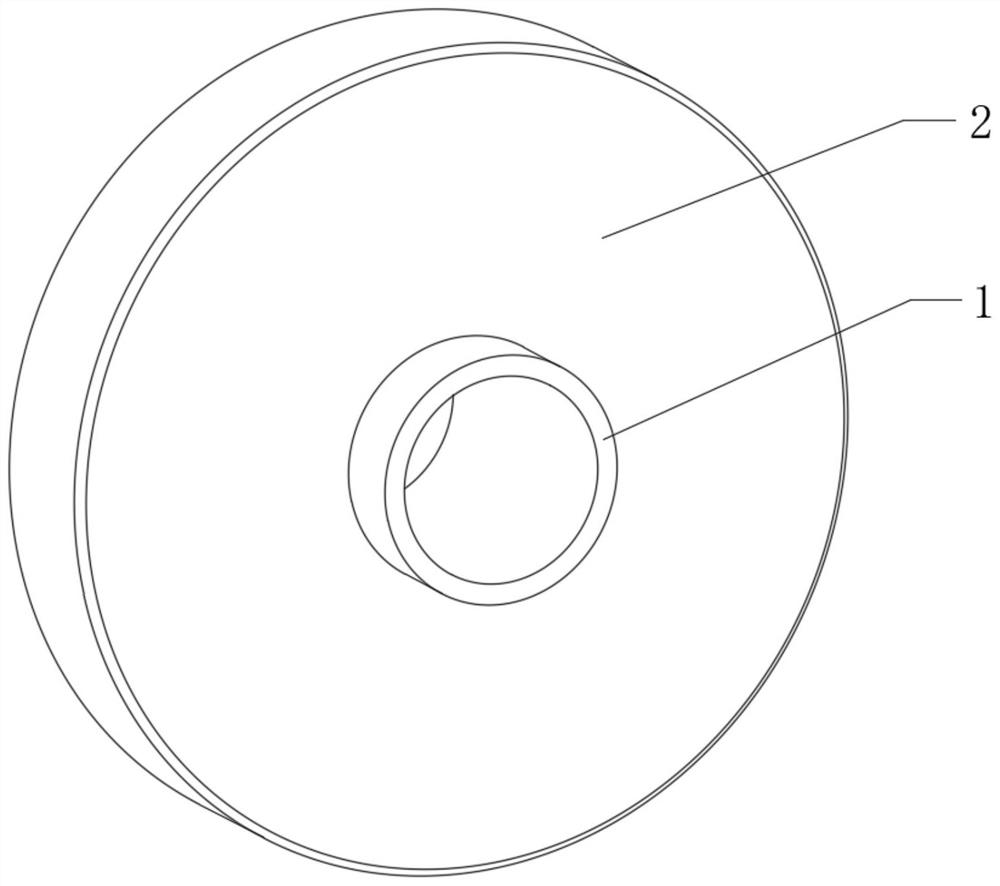

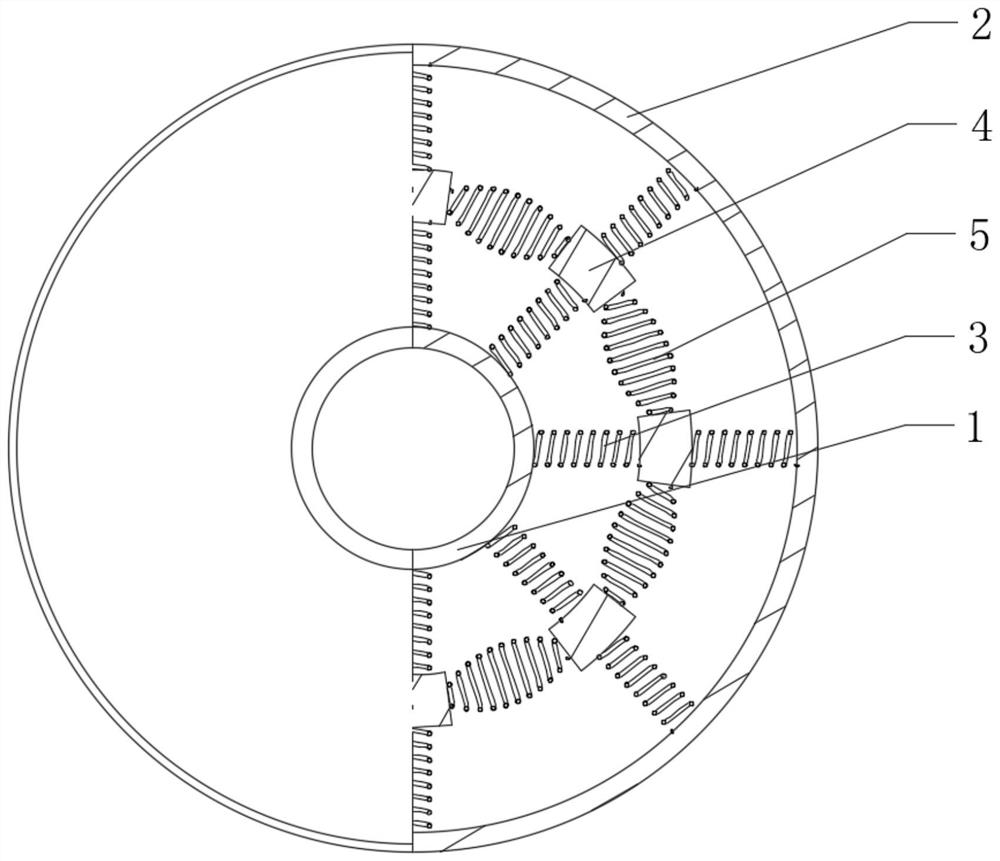

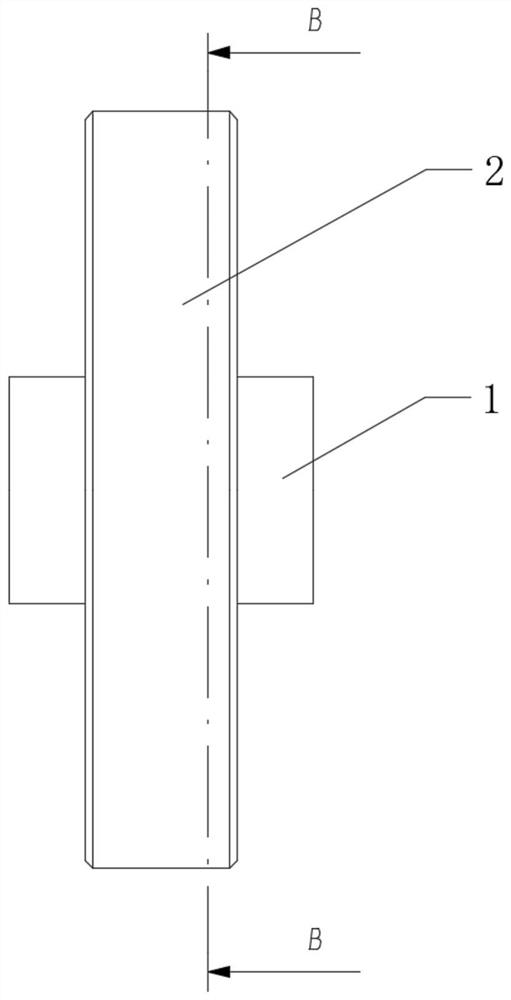

[0028] Such as Figure 1 to Figure 6 As shown, an adaptive order tracking vibration damping metamaterial shaft structure provided by the present invention includes a shaft base 1, a housing 2 and a unit cell unit, and the unit cell unit includes a constant stiffness spring 3, a mass block 4 and a variable stiffness spring 5. Mass blocks 4 are respectively connected to shaft base 1 and housing 2 through constant stiffness springs 3 , and adjacent mass blocks 4 are connected through variable stiffness springs 5 .

[0029] In this embodiment, there are eight mass blocks 4 and they are annularly distributed around the shaft base 1 , the number of constant stiffness springs 3 is sixteen, and the number of variable stiffness springs 5 is eight. During actual use, the number of mass blocks 4 can be increased or decreased according to usage requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com